The ZTRFM Metal Ridge Cap Roof Tile Roll Forming Machine is designed for the efficient and precise production of metal ridge caps used at the apex of roofs to prevent water and snow penetration. It features a dedicated profile system, forming speed of 12–15 m/min, and is built with high-quality components from well-known brands. With 15 forming stations, a welded steel frame, and a hydraulic cutting system, this machine ensures stable performance, durability, and accuracy. Ideal for factory-based manufacturing, the machine offers easy installation, low noise, and high efficiency. It is especially suitable for clients seeking consistent output and long-term reliability in roofing material production.

The Ridge Cap Roof Tile Roll Forming Machine is designed to produce ridge caps that connect seamlessly with roof tiles, providing essential protection against rain and snow infiltration. Each machine is dedicated to forming one specific ridge cap profile

Main Specifications of Metal Ridge Cap Roof Tile Roll Forming Machine

| Item | Specification |

| Forming Steps | 15 stations |

| Shaft Diameter | 80 mm |

| Design Type | Middle plate welded structure |

| Machine Frame | 350# H-beam welded frame |

| Roller Material | 45# steel with hard chrome plating |

| Shaft Material | 45# steel |

| Working Speed | 7–15 meters per minute |

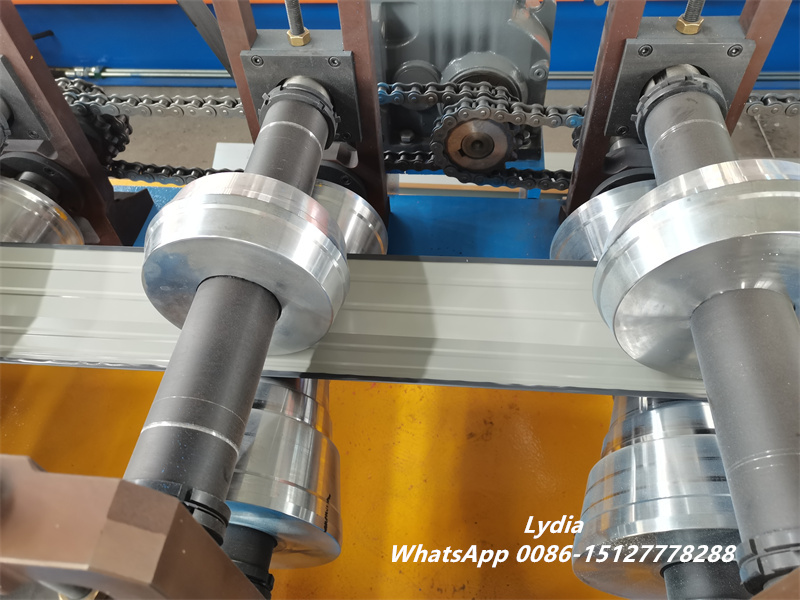

| Transmission Method | Chain-driven |

| Main Motor Power | 5.5 kW |

| Cutting Type | Hydraulic cutting |

| Machine Dimensions | 5600 mm × 600 mm × 800 mm |

Key Advantages

- There are two rollers at the feeding part, to put raw material between them to manufacture and process, which can guarantee the products are neat, parallel, and everything is uniform.

- There are two wheels on the two sides, which can help the operator adjust the raw material easily and make the sheet in the right

- There are manual cutters before roll forming, you can cut the raw material at any length as you need.

| 1 | Rolling shaft | Shaft material: 45# steel |

| 2 | Shaft diameter: 70 mm | |

| 3 | Tempering treatment | |

| 4 | Roller | Roller material: 45# steel |

| 5 | Chromed treatment | |

| 6 | Rolling station number | 12 stations |

| 7 | Work speed | 0-15 m/min |

| 8 | Machine frame | Carbon steel welded structure |

| 9 | Machine body | 350# H steel welded |

| 10 | Bearing | famous Chinese brand Harbin |

| 11 | Work power | 5.5 kw |

| 12 | Transmission | By chains, size of chain: 1 inch |

| Advantage:

1. For all of our rollers, spacers, and shafts, we all mark numbers on them, it is very convenient for you to maintain the machine in the future. 2. There are ball bearings inside the rollers to make all the rollers run at the same speed when the machine is running. 3. Because the rollers inside with ball bearings, our rollers are bigger than others, so the work speed is faster. 4. All rollers and spacers we do 3mm thickness chrome coating, to increase hardness and anti-rust. Some factories may use a 1-2mm chrome coating. 5. With two gears outside, make the shaft run from passive to active, with more power running faster. |

||

Engineered by Zhongtuo for Precision and Surface Protection As patio and pergola structures become more

Zhongtuo Industrial Cable Tray Roll Forming Production Line Zhongtuo Cable Tray Roll Forming Machine is

Full Automatic Steel Supermarket Shelves Storage Rack Upright Pillar Roll Forming Machine Improve Warehouse Efficiency

Cable Ladder & Cable Tray Roll Forming Machine High-Efficiency Steel Side Rail Forming Machine for

STAY IN THE LOOP