Trimdek Sheet Roll Forming Machine For Making Trimdek Roof Sheets And Walling in Australia

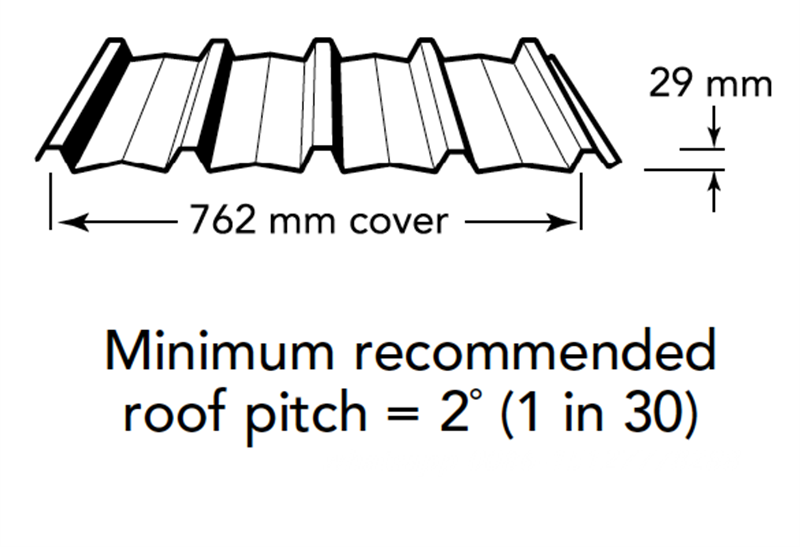

ZTRFM’s Trimdek Sheet Roll Forming Machine For Making Trimdek Roof Sheets And Walling is engineered in China to meet and exceed Australian safety regulations and performance expectations. Designed for the long‑span Trimdek profile, it delivers a lightweight yet exceptionally sturdy cladding solution, ideal for roofs and walls. With a coverage width of 762 mm and a 29 mm rib height including an anti‑capillary groove, this machine produces panels that are both economical and watertight—even on pitches as low as two degrees.

Key Features of Trimdek Sheet Roll Forming Machine

With its wide pans, square ribs, bold ribs and fluted pans, Trimdek roofing and cladding delivers a sleek, modern roofline and subtle linear effect at low pitches while providing outstanding structural strength and exceptional spanning capability for enhanced design flexibility.

– Long‑Span Design: Allows wider support spacings for faster, more cost‑effective installation.

– Optimized Rib Profile: 29 mm ribs with a capillary groove ensure superior drainage and leak resistance.

– Coverage & Dimensions: Offers 762 mm cover width (820 mm overall sheet width) in steel thicknesses from 0.42 to 0.48 BMT.

– High‑Strength Materials: Compatible with 500 MPa yield‑strength steels, maximizing durability without excessive brittleness.

The Drawing Profile:

Technical Specifications of Trimdek Sheet Roll Forming Machine

| Component | Specification | Notes |

| Raw Material | Galvanized steel | Customer specified |

| Material Thickness | 0.3–0.7 mm | Adjustable per order |

| Decoiler Capacity | 7.5 tonne; Ø 450–600 mm inner diameter | Manual (standard) or hydraulic (optional) |

| Roll Forming Stations | 18 stations (20–22 rollers total) | GCr12MoV rollers; 75 mm shafts hardened |

| Forming Speed | 15–20 m/min (no holes); 0–20 m/min (with holes) | PLC controlled |

| Machine Frame | Vertical arch weldment; precision machined | Steel plate welded structure |

| Drive & Power | Gearbox transmission; covered for safety | 7.5 kW motor + 3 kW auxiliary |

| Bearings | Harbin brand | Proven reliability |

| Safety & Finish | Full guarding; high quality paint finish | Burr free, rust resistant, neat cable organization |

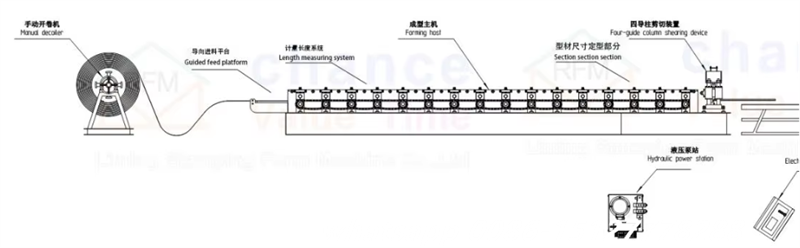

Trimdek Sheet Roll Forming Machine For Making Trimdek Roof Sheets And Walling – Production Workflow

- Coil Unloading & Decoiling

- Sheet Guiding & Feeding

- Roll Forming

- Precision Sizing

- Hydraulic Cutting

- Finished Panel Splicing

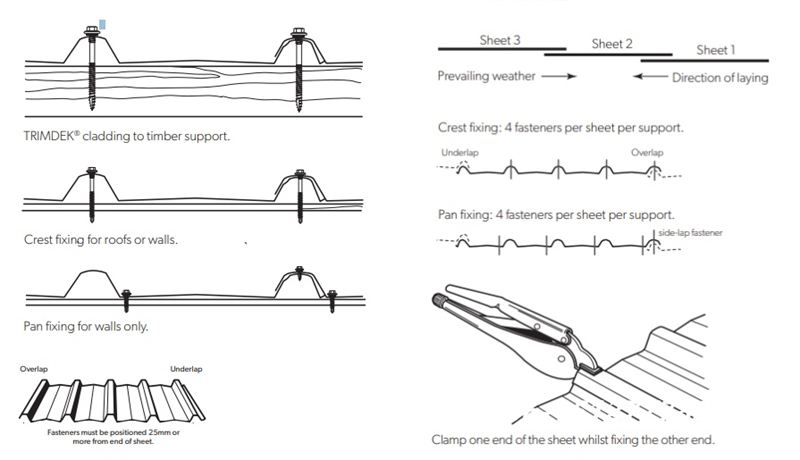

Trimdek Sheet Roll Forming Machine For Making Trimdek Roof Sheets And Walling – Installation Guidelines and Applications & Benefits

The More Pictures of the Machine

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP