Container house frame making machine

Australian specification standards shipping living container house frame making machine is designed to make the container house frame in batch and fully automatically.

modular house frame making machine

What is a living container house?

The container house is a building system that once again hits the fashion trend, and can be moved to various places anytime and anywhere, bringing people a more convenient and comfortable life. The solar photovoltaic panel can be used for indoor electricity, the solar water heater can be heated and supplied with water, and the indoor shower and domestic water are discharged by the sewage treatment system for reuse. Depending on the number of people, container houses of different sizes can be made.

modular house frame making machine

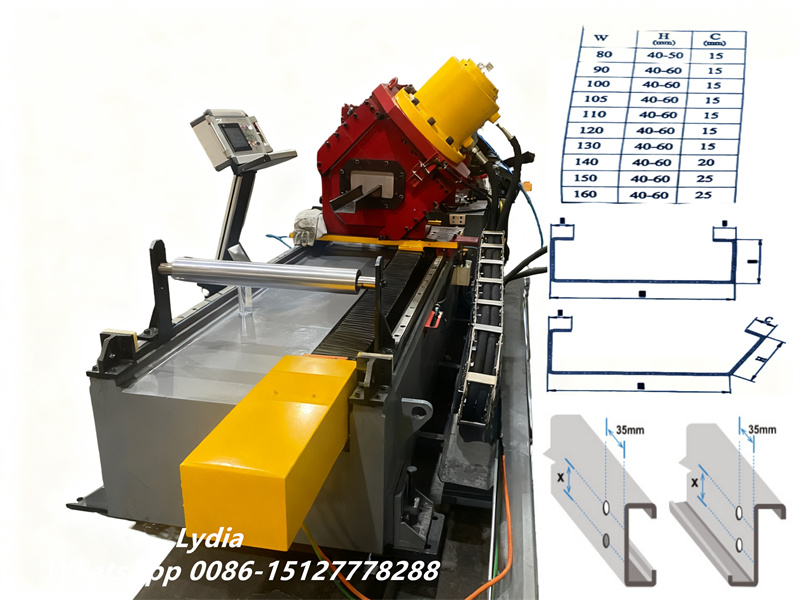

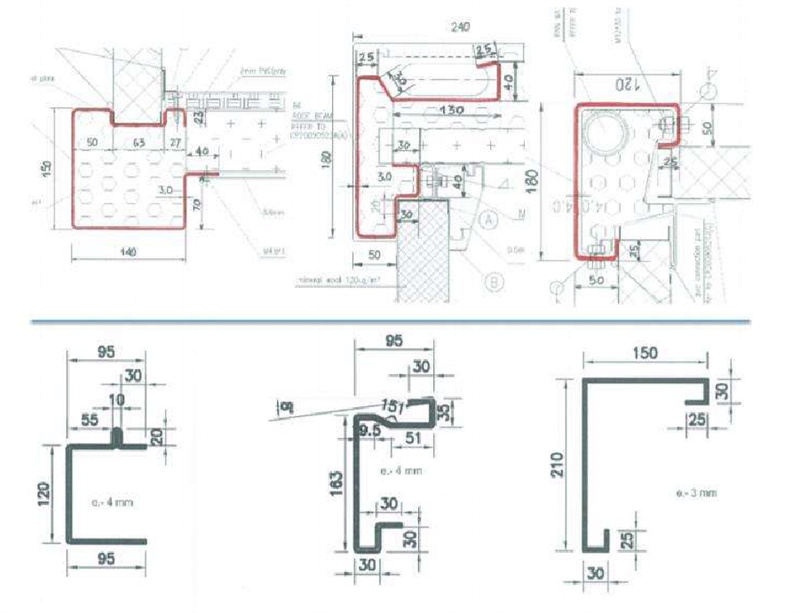

In this article, I will take one part, the container house pillar frame, for example, to show you how the machine makes it.

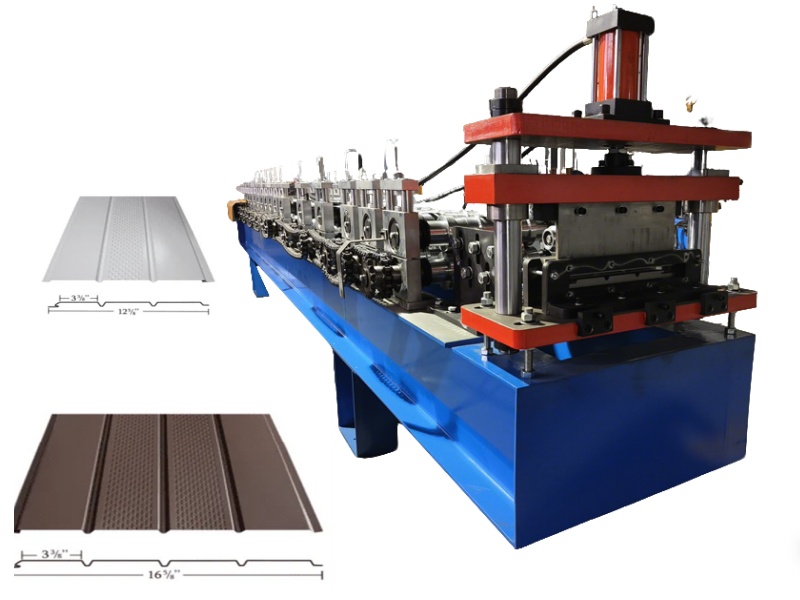

The container house frame making machine we design like follows:

Features of the Australian specification standards shipping living container house frame making machine:

- It uses the gearbox as a transmission to make sure the power can be given evenly.

As the material thickness could reach 4.0mm, the machine should be strong enough to make it work.

- It uses the hydraulic molding cutting to make sure the shape will not be changed.

- The molds will be processed accurately to ensure the shape is accurate and beautiful.

- The container house frame pillar machine working speed can reach 25 meters per minute.

- All the brands of the motor and PLC, we use the world-famous and then it can make sure the good working effect.

Automatic Container House Frame Roll Forming Machine

Here are some container house frame-making machine parameters for your reference:

Product raw material: galvanized sheet, Thickness: 3.0~4.0mm, Strength: Q235

The main unit consists of 26 rolls.

Shaft diameter: 95 mm, quenching and tempering finishing;

Roller material GCr15 heat treatment finishing,

Living container house frame making machine

The roller is completely blackened, and the forming speed is 15m/min.

- Wu roll shaping device;

- Hydraulic control center ; sleeve; (power: 55KW, with air conditioning cooling device)

- Hydraulic back punching device;

Including: punching a combined mold sleeve;

- Hydraulic forming shearing device;

Blanking shear, shearing tool material: Cr12MoV, heat treatment;

- Computer-controlled consoles;

Control quantity and automatic cutting length;

System components: PLC, touch screen (Delta), encoder (OMRON), etc.;

Shear length tolerance ≤ ± 2.0mm.

Specification Standards Shipping Living Container House Frame Making Machine The Australian specification standards shipping living

Stainless Steel & Aluminum Door Frame Making Machine The stainless steel and aluminum door frame

The ZTRFM Soffit Panel Roll Forming Machine is engineered for manufacturers who require fast, stable,

Cee & Zee Eave Struts Roll Forming Machine for Metal Buildings High-Performance Purlin Mill In

STAY IN THE LOOP