Cee & Zee Eave Struts Roll Forming Machine for Metal Buildings High-Performance Purlin Mill

In metal building construction, speed, accuracy, and consistency matter more than ever. Therefore, choosing the right Cee & Zee Eave Struts Roll Forming Machine becomes a key factor in producing high-strength structural components. Designed for continuous, stable, and high-speed production, this metal building purlin mill offers superior performance for large-scale manufacturing needs.

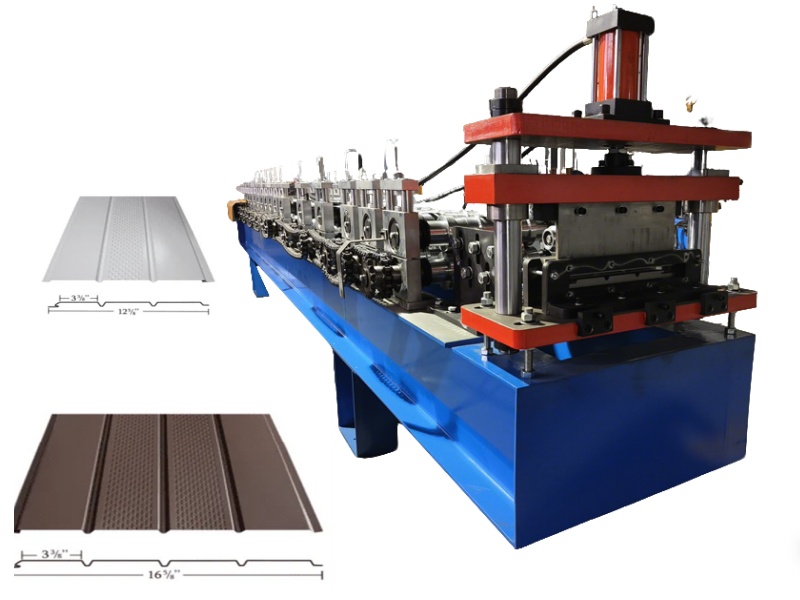

Cee Zee purlin mill

Our Cee and Eave Strut Roll Forming Line is engineered by ZTRFM Machine and Zhongtuo Machine, combining precision design with a robust mechanical structure to ensure reliable forming results for steel structures, warehouses, workshops, and industrial buildings.

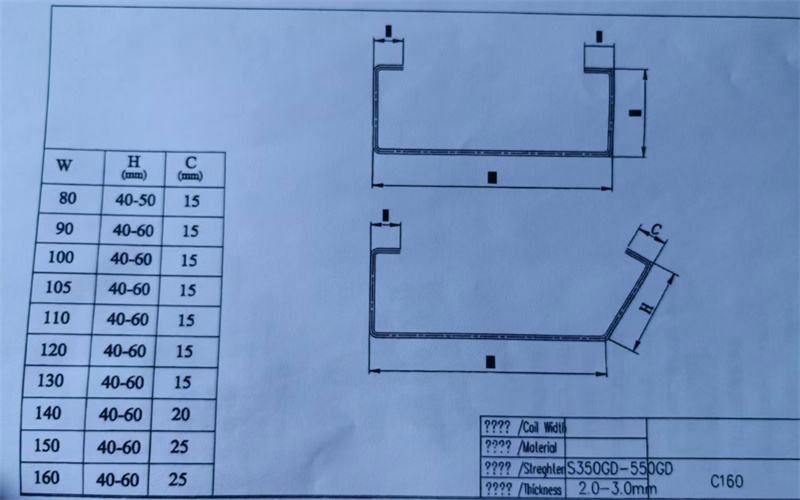

Cee & Zee Eave Strut Roll Forming Machine Configuration Table

| Section | Function Description |

|---|---|

| Hydraulic Decoiler with Loading Cart | Automatically loads and unwinds steel coils for smooth feeding. |

| Shearing & Butt-Welder | Cuts the material head and welds coil ends for nonstop production. |

| Horizontal Accumulator | Stores material temporarily to maintain continuous forming. |

| Leveling Bridge Unit | Level incoming sheets to ensure accurate forming. |

| Looper 1# | Aligns steel strips before entering the punching station. |

| Isolated Punch Station (8 Punch Seats) | Performs customized punching patterns efficiently. |

| Looper 2# | Stabilizes sheet entry into the forming machine. |

| Roll Forming Section | Shapes Cee and Zee Eave Struts with high precision. |

| Flying Cutting Die | Cuts profiles at high speed without stopping the line. |

| Output Conveyor | Transfers finished profiles smoothly. |

| Stacker | Automatically stacks purlins for easy packaging. |

| Electric Control Cabinet | The entire line is controlled by PLC for safe and automated operation. |

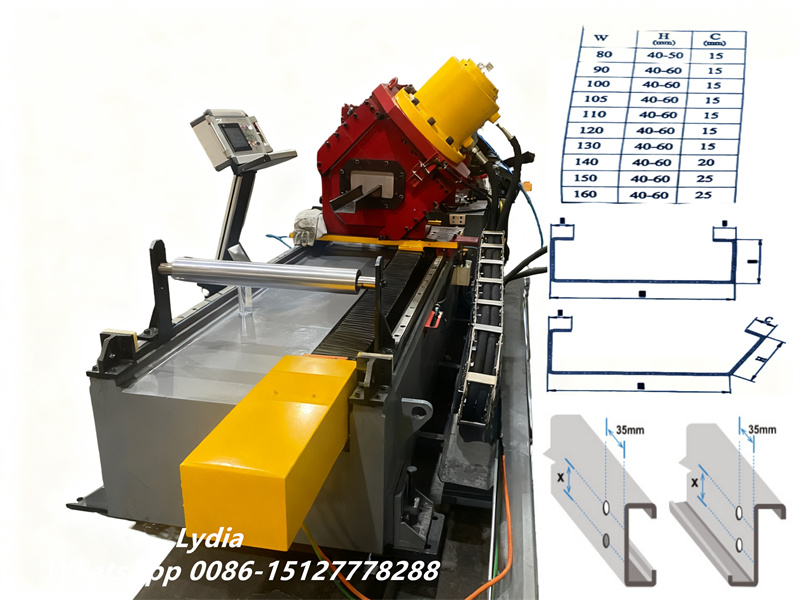

C/Z purlin roll forming machine

What Is a Cee & Zee Eave Strut Roll Forming Machine?

A Cee and Eave Strut roll forming machine is specialized forming equipment used to manufacture structural eave struts for metal buildings. These components provide essential support to roofs and wall systems. Because eave struts connect roof panels and wall panels, they must be formed with precision and strength — exactly what our purlin mill ensures.

Unlike traditional manual forming, our automatic production line offers:

- Consistent output

- High forming accuracy

- Continuous high-speed production

- Flexible profile adjustment

Key Features of Our Metal Buildings Purlin Mill

1. Fully Automatic High-Speed Operation

The system uses loopers and an accumulator, ensuring that punching, forming, and cutting remain continuous — significantly boosting production efficiency.

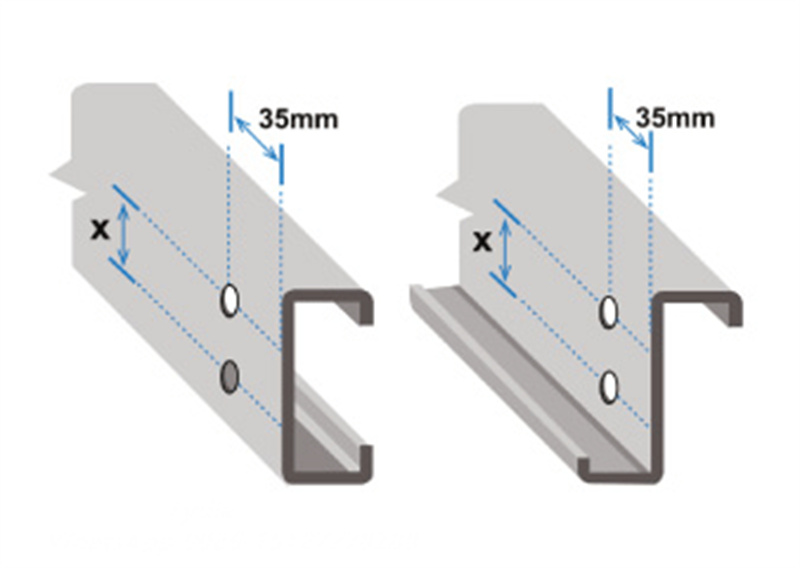

2. Precision Punching for Structural Applications

With an isolated punch station containing 8 punching seats, you can achieve multiple hole patterns for different structural requirements.

Zee Eave Strut roll forming machine

3. Heavy-Duty Roll Former for Cee & Zee Eave Struts

The forming section uses high-strength rollers and a rigid machine base to ensure accuracy even during long-term production.

4. Flying Cutting System

The automatic flying saw cutting die ensures profile lengths remain accurate without stopping the line, increasing output dramatically.

Eave strut roll forming line

5. Intelligent PLC Control System

The full line uses Delta or Siemens control options, giving you stable, safe, and user-friendly operation.

Why Choose ZTRFM Machine for Your Eave Strut Production?

Because metal building manufacturers need equipment that performs reliably even under heavy workloads, ZTRFM Machine and Zhongtuo Machine design every purlin mill with durability and precision in mind. Moreover, our engineering team ensures that each forming line is easy to operate, simple to maintain, and cost-effective for long-term production.

You’ll benefit from:

✔ Precision forming quality

✔ Custom profile design (Cee, Zee, eave struts)

✔ High production speed

✔ Long service life

✔ Global installation & training support

Applications of Cee & Zee Eave Struts

Our machine is widely used in manufacturing:

- Metal building frameworks

- Steel structure roofing

- Wall support systems

- Industrial warehouses

- Commercial workshops

- Agricultural steel barns

In summary, if you want a reliable, efficient, and high-accuracy solution for producing Cee & Zee Eave Struts, this roll forming line is your best choice. With advanced automation, flexible punching options, and stable forming performance, it is designed specifically for modern purlin manufacturing in metal buildings.

Stainless Steel & Aluminum Door Frame Making Machine The stainless steel and aluminum door frame

The ZTRFM Soffit Panel Roll Forming Machine is engineered for manufacturers who require fast, stable,

We are pleased to announce the successful delivery of our high-performance double-layer trapezoidal RIB metal

DIN Rail Roll Forming Machine Automatic DIN Rail Channel Making Line What is DIN Rail?

STAY IN THE LOOP