Width Adjustable Metal U Channel Steel Lining Profile Rolling Machine

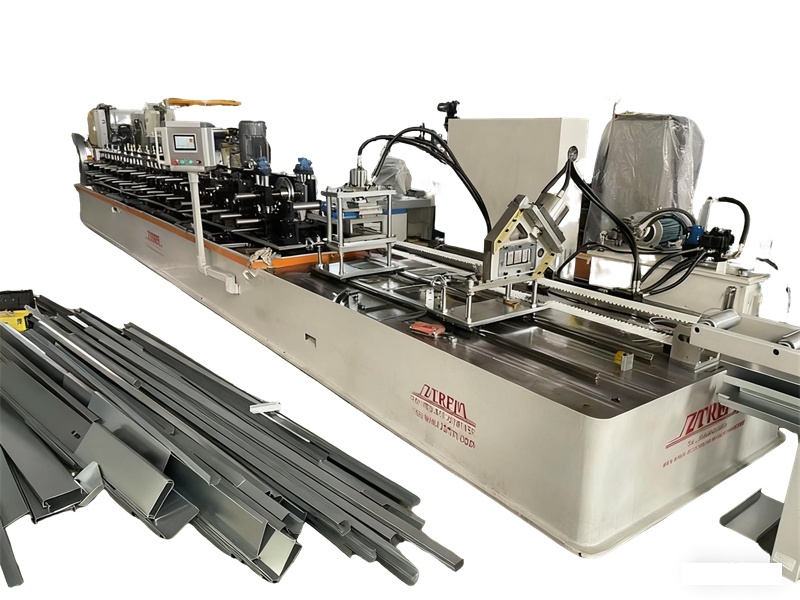

The Width-Adjustable Metal U-Channel Steel Lining Profile Rolling Machine is a high-precision forming line specifically designed for manufacturing steel reinforcement channels. This machine provides full flexibility for different profile dimensions and is ideal for modern construction material factories and metal framing component manufacturers across the United States.

Drywall C U Channel Machine

Thanks to its adjustable design and servo-controlled system, one machine can produce multiple U channel sizes without the need to change rollers, significantly improving productivity and reducing production costs.

Main Features of U Channel Roll Forming Machine

The Width-Adjustable U-Channel Roll Forming Machine offers a fully automated forming process with precise dimensional control.

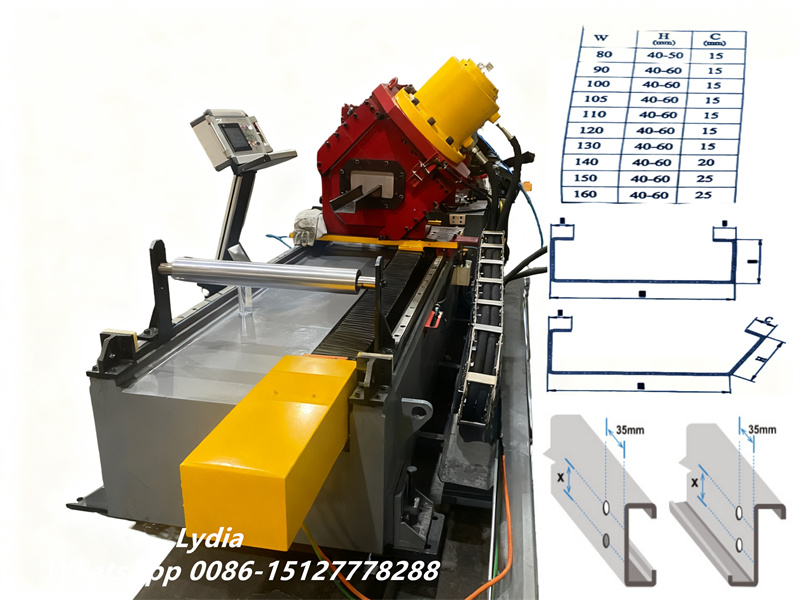

Adjustable Dimensions

- Bottom width: 10–40 mm

- Height: 5–40 mm (adjustable by changing coil width)

Automation and Speed

- PLC control for automatic size adjustment

- Maximum forming speed: with punching 50m/min, without punching 70m/min

- Servo tracking cutting system ensures clean, accurate cuts

Material Range

- Suitable for galvanized steel, cold-rolled steel, or stainless steel

- Coil thickness: 0.8–1.2 mm

Drywall C U Channel Machine

Technical Specifications of the track and stud Roll Former

| Item | Specification |

|---|---|

| Roller Material | GCr15, CNC machined, heat-treated (HRC56–62) |

| Frame Structure | 8 mm welded steel plate with cast iron archway |

| Roller Shaft Diameter | 70 mm (Material: 45# steel) |

| Drive Motor | 15 kW |

| Transmission | Chain drive |

| Forming Stations | 9 forming steps |

| Processing | Rough machining → Heat treatment → Precision finishing → Hard chrome plating |

This cold roll forming process gradually bends the steel strip into the required U-channel shape.

Each roller station ensures the profile maintains perfect accuracy and a smooth finish.

Drywall C U Channel Machine

Drywall C U Channel Machine

Drywall C U Channel Machine

Advantages of a cold roll forming machine

- Produces multiple U-channel sizes with one machine

- Fully automatic PLC and servo control system

- Precise dimension change without manual roller adjustment

- Heavy-duty gearbox and frame for stability

- Meets U.S. market standards for door and window reinforcement production

- Ideal for manufacturers of steel stud, track, and lining profiles

Drywall C U Channel Machine

Drywall C U Channel Machine

Drywall C U Channel Machine

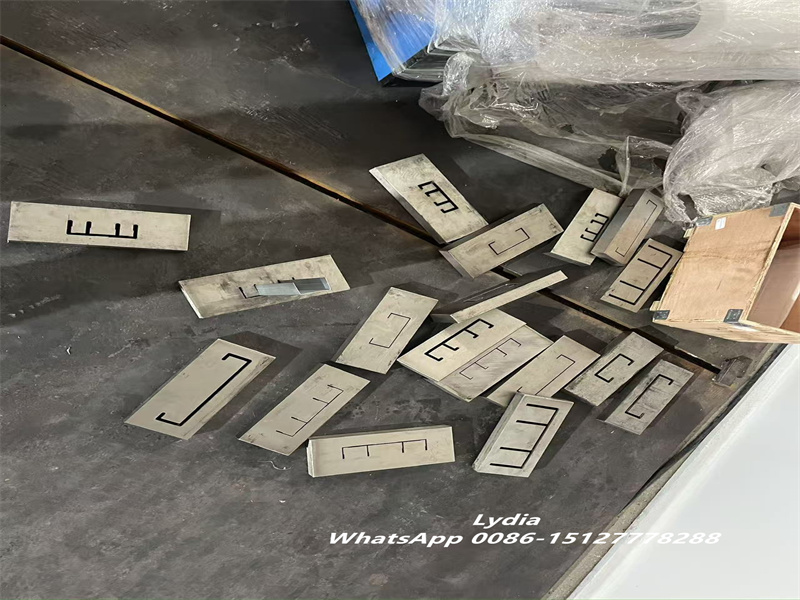

Applications of Drywall CU Channel Machine

- PVC Door and Window Reinforcement

- Metal Stud and Track Systems

- Drywall Framing Profiles

- Light Steel Keel and Ceiling Support Channels

- Construction and Building Material Production

Stainless Steel & Aluminum Door Frame Making Machine The stainless steel and aluminum door frame

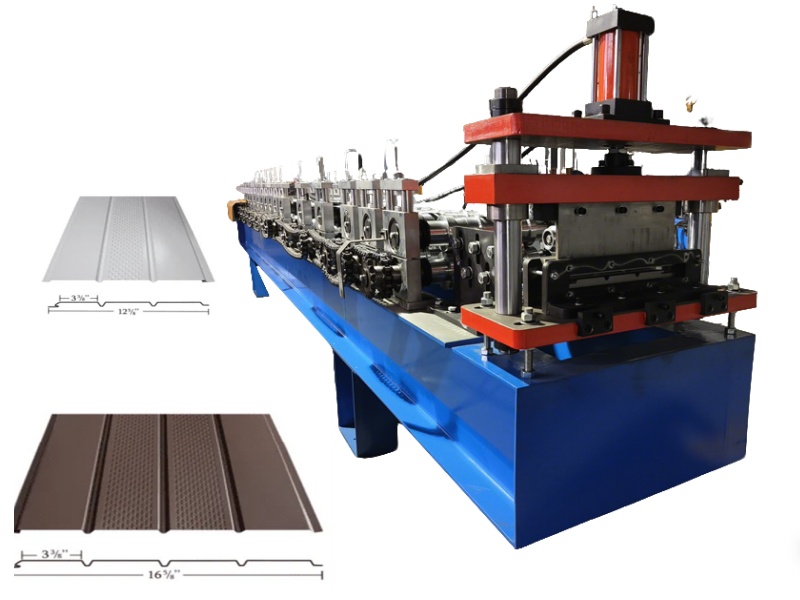

The ZTRFM Soffit Panel Roll Forming Machine is engineered for manufacturers who require fast, stable,

Cee & Zee Eave Struts Roll Forming Machine for Metal Buildings High-Performance Purlin Mill In

We are pleased to announce the successful delivery of our high-performance double-layer trapezoidal RIB metal

STAY IN THE LOOP