What is a Cable Tray?

A cable tray, also known as a cable bridge, is designed to support and protect cables in various applications. By placing cables inside the tray, they are shielded from external damage and organized for safer installation. Cable trays are widely used in public and industrial facilities, such as underground parking lots, libraries, thermal power plants, and chemical factories.

Cable Tray Cover Roll Forming Machine

Types of Cable Trays

- U-Type Cable Tray

- Tray-Type Cable Tray

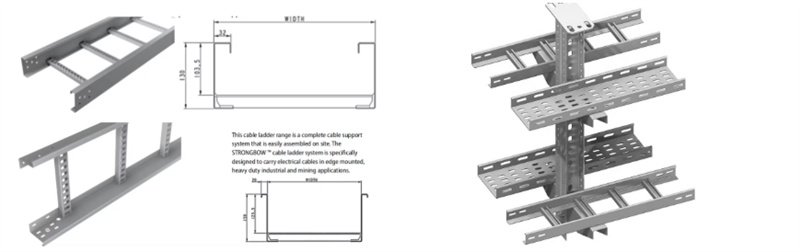

- Ladder-Type Cable Tray

- Grid-Type Cable Tray

Most systems are composed of support arms and installation accessories, making them adaptable for different environments.

Cable Tray Roll Forming Production Line

The roll forming production line is the most widely used method for manufacturing cable trays. It supports multiple production batches and offers large-scale manufacturing capabilities.

Cable Tray Roll Forming Machine

Advantages:

- Labor-saving and high automation

- High production efficiency

- Reduced material waste

Limitations:

- Requires large floor space

- High power consumption

- Less suitable for small-batch production

- Limited flexibility for combining different coil and block types

Optimal working area: 40m × 4m. This setup is ideal for producing long-span bridges but requires a large workshop, which may not be suitable for all customers.

Cable Tray Roll Forming Machine

Third-Generation Cable Tray Machine

To address customer needs, our company has developed the third-generation cable tray machine, which integrates rolling and bending technology.

Key Features:

- Multi-function design: Each unit can operate independently or in combination.

- Additional functions: Capable of producing cover plates, Tipon, and Elbow Tipon simultaneously.

- Reduced working area requirement: Only 20m × 4m.

- Limitation: Can only produce standard 2-meter bridges or up to 4-meter bridges within a specified range.

Ladder Cable Tray Machine

Customers who already own the third-generation cable tray machine can easily expand into ladder cable tray production with minimal additional cost.

- Ladders can be directly formed on the cable bridge.

- Cross arms can be shared with the bridge structure.

- Automatic size adjustment: Supports 100 / 150 / 200 models.

- Material thickness: 1.0–3.5 mm.

- Requires only minimal additional cross-arm equipment.

For specific needs, a dedicated ladder machine can also be provided.

Cable Tray Roll Forming Machine

Cable Tray Roll Forming Machine

Tray-Type Cable Tray Production

Tray-type production is generally more costly compared to ladder-type trays.

Options:

- Ordinary punching trays: Produced using a 400T hydraulic punching machine + combined punching system + 2–3 forming machines.

- European standard trays / energy-saving trays: Require a complete production line worth around 2 million RMB, with dedicated molds for each model.

Specifications:

- Waist height: ≤100 mm (special models <150 mm)

- Bottom width: ≤400 mm

Many customers choose to invest in full-model forming machines, but this can lead to unnecessarily high costs. Selecting only the required models is a more economical approach.

Common Misunderstandings About Cable Tray Machines

A frequent misconception is that customers need to purchase all possible equipment and accessories upfront. In reality, this is not necessary due to China’s mature industrial supply chain.

Recommended Strategy:

- Start with large-volume, high-profit, and simple products.

- Outsource accessories such as bends or spare parts at a very low cost.

- Expand your production line gradually as your business grows.

Step-by-step investment ensures maximum value, reduces capital costs, and simplifies production management.

Common Misunderstandings About Cable Tray Machines

Cable tray forming equipment offers a range of solutions for different production needs. While roll forming lines provide efficiency and scale, the third-generation cable tray machine introduces flexibility and space-saving advantages. By understanding the real needs of your business and avoiding unnecessary investment, you can optimize production efficiency and achieve sustainable growth.

Engineered by Zhongtuo for Precision and Surface Protection As patio and pergola structures become more

Zhongtuo Industrial Cable Tray Roll Forming Production Line Zhongtuo Cable Tray Roll Forming Machine is

Full Automatic Steel Supermarket Shelves Storage Rack Upright Pillar Roll Forming Machine Improve Warehouse Efficiency

Cable Ladder & Cable Tray Roll Forming Machine High-Efficiency Steel Side Rail Forming Machine for

STAY IN THE LOOP