This automated production line represents a significant advancement in light steel framing technology. Designed specifically for residential, commercial, and industrial construction projects, it offers a superior alternative to traditional wood framing. The system combines high production efficiency with exceptional precision, delivering durable steel components that meet the demands of contemporary architecture.

Light Gauge Steel Framing Machine

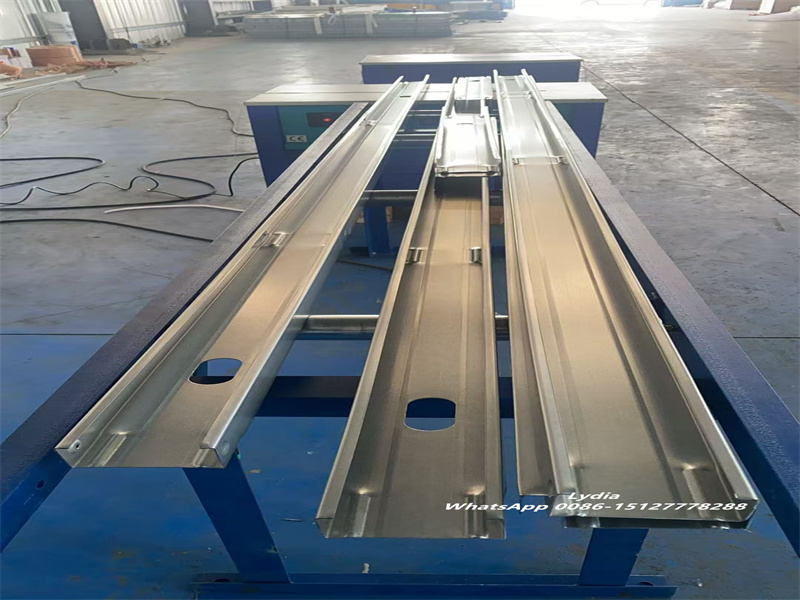

Technical Specifications of Light Gauge Steel Framing Machine

The system accommodates galvanized or painted steel coils with thickness ranging from 0.8 to 1.0 mm. Its reinforced vertical arch design ensures stability during high-speed operation, reaching up to 30 meters per minute. The precision-ground 40Cr alloy drive shafts deliver reliable performance, while the 7.5 kW servo motor provides consistent power. The hydraulic servo shear mechanism, equipped with Cr12Mov blades, maintains cutting precision through over one million cycles. With a throughput capacity of 14-20 linear meters per minute, the system meets demanding production schedules.

Light Gauge Steel Framing Machine

Structural Advantages of Light Gauge Steel Framing Machine

Compared to conventional wood framing, this system offers multiple benefits. The steel components demonstrate complete resistance to moisture damage and insect infestation, addressing two major limitations of wood construction. They maintain dimensional stability without warping or shrinkage, even in varying climatic conditions. The material’s inherent fire resistance significantly enhances building safety. From an environmental perspective, the system uses recyclable materials, reducing construction waste. The standardized components enable rapid on-site assembly, while the precision manufacturing process minimizes material waste and associated cleanup costs.

Light Gauge Steel Framing Machine

Applications of Light Gauge Steel Villa Frame Keel Roll Forming Making Machine

The framing system finds extensive use across various construction sectors. It’s particularly suitable for educational facilities, healthcare buildings, and hospitality structures where durability and precision are paramount. The technology also serves industrial plants and storage facilities exceptionally well. For wall systems, it efficiently produces both load-bearing and non-load-bearing components, making it ideal for modular and prefabricated construction projects

Processing Flow

Decoiler → Feeding → Material Leveling → Roll Forming → Punching → Post Cutting → Finished Product Output

System Components of Light Gauge Steel Framing Machine

The material handling unit features a 1.5-ton capacity coil holder with manual expansion adjustment. Its dual-clamp central braking system and integrated leveling mechanism with four guide rollers ensure smooth material feeding. The punching station offers multi-function capability, creating standard 3.5 mm fastener holes and 16.5 mm threaded receptacles with servo-controlled precision.

The forming section boasts 80mm diameter main shafts made from 45# steel, combined with hardened, polished forming rollers for consistent quality. The stable arch-frame construction maintains alignment during operation. For cutting operations, the guided shear mechanism delivers clean, deformation-free sections using high-durability Cr12Mov blades.

Control is managed through an industrial PC with 17″ human-machine interface, featuring network and USB data connectivity. The system incorporates premium components including Panasonic programmable controllers, Schneider electrical systems, OMRON precision encoders, and INVT servo drive technology for reliable operation.

Key Benefits of Light Gauge Steel Framing Machine

This production system delivers enhanced productivity through optimized high-volume output capabilities. Its precision engineering ensures tight tolerances and consistent quality across all produced components. The adaptable configuration allows quick changeovers between different profiles, increasing operational flexibility. Most importantly, the weather-resistant structural solutions offer long-term performance advantages over traditional building materials.

Light Gauge Steel Framing Machine

Light Gauge Steel Framing Machine

Light Gauge Steel Framing Machine

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP