This roll forming machine is specially designed to produce metal studs, track, furring channel, and omega profiles at high speed with excellent precision and automation. It is ideal for lightweight steel framing systems used in walls, ceilings, and partitions.

stud and track purlin machine

Machine Features of Omega Purlin Roll Forming Machine:

The hat channel roll forming machine is composed of several key components, including a decoiler, feeding and leveling system, pre-shearing unit, roll forming section, hydraulic post-cutting device, run-out table, hydraulic station, and a PLC control system.Designed for long production runs, this machine delivers consistently accurate profiles with smooth, well-defined shapes.

stud and track purlin machine

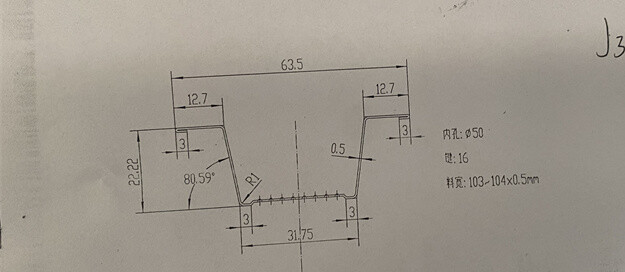

Technical Specifications of Hat Channel Roll Forming Machine

| No. | Item | Specification | Optional |

| 1 | Suitable Material | Galvanized Coil, PPGI, Carbon Steel Coil Thickness: 0.25–1.2 mm Yield Strength: 250–550 MPa Tensile Strength: G350–G550 MPa |

|

| 2 | Forming Speed | 10–40m/min | Customizable |

| 3 | Forming Stations | 8–14 | |

| 4 | Decoiler | Manual Decoiler | Hydraulic or Double Head Decoiler |

| 5 | Main Motor Brand | Sino-German Brand | Siemens |

| 6 | PLC System | Panasonic | Siemens |

| 7 | Inverter | Yaskawa | |

| 8 | Driving System | Chain Drive | Gearbox Drive |

| 9 | Rollers Material | Steel #45 | GCr15 |

| 10 | Station Structure | Wall Panel Station | Forged Iron / Torri Stand |

| 11 | Punching System | Not Included | Hydraulic / Mechanical Punch Press |

| 12 | Cutting System | Post-Cutting | Pre-Cutting |

| 13 | Power Supply | 380V / 60Hz / 3 Phase | Customizable |

| 14 | Machine Color | Industrial Blue | Customizable |

Key Component Details of the Hat Channel Roll Forming Machine

3-Ton Manual Decoiler

Max Weight: 3 Tons

Coil Inner Diameter: 450–550 mm

Structure: Steel plate & C-beam welded

Function: Manual tensioning & support of coils for feeding

Feeding & Guiding Device

Width Range: 200–300 mm

Feeding Type: Manual

Function: Prevents deviation before roll forming

Roll Forming Machine

Base Structure: Welded C-beam with integrated drive

Forming Speed: 12–15 m/min

Voltage: 415V / 50Hz / 3 Phase

Roller Material: GCr15, CNC machined, HRC58–62, chromed 0.05 mm

Shaft: ASTM1045, Ø60 mm

Forming Steps: 18

Transmission: Gear drive, 5.5 kW Guomao Motor

Side Wall Thickness: 18 mm

Hydraulic Cutting Unit

Cutting Type: Stop-to-cut hydraulic shear

Motor Power: 4 kW

Working Pressure: 12–16 MPa

Blade Material: Cr12, heat treated

Length Measurement: Omron encoder

Tolerance: ±1.0 mm

stud and track purlin machine

stud and track purlin machine

stud and track purlin machine

stud and track purlin machine

Engineered by Zhongtuo for Precision and Surface Protection As patio and pergola structures become more

Zhongtuo Industrial Cable Tray Roll Forming Production Line Zhongtuo Cable Tray Roll Forming Machine is

Full Automatic Steel Supermarket Shelves Storage Rack Upright Pillar Roll Forming Machine Improve Warehouse Efficiency

Cable Ladder & Cable Tray Roll Forming Machine High-Efficiency Steel Side Rail Forming Machine for

STAY IN THE LOOP