We are pleased to announce the successful delivery of our high-performance double-layer trapezoidal RIB metal roof wall panel tile roll forming machine to our clients in the United States. Designed specifically for the North American construction and roofing market, this machine combines precision, efficiency, and versatility in a compact system.

High-speed double-layer roofing sheet forming machine

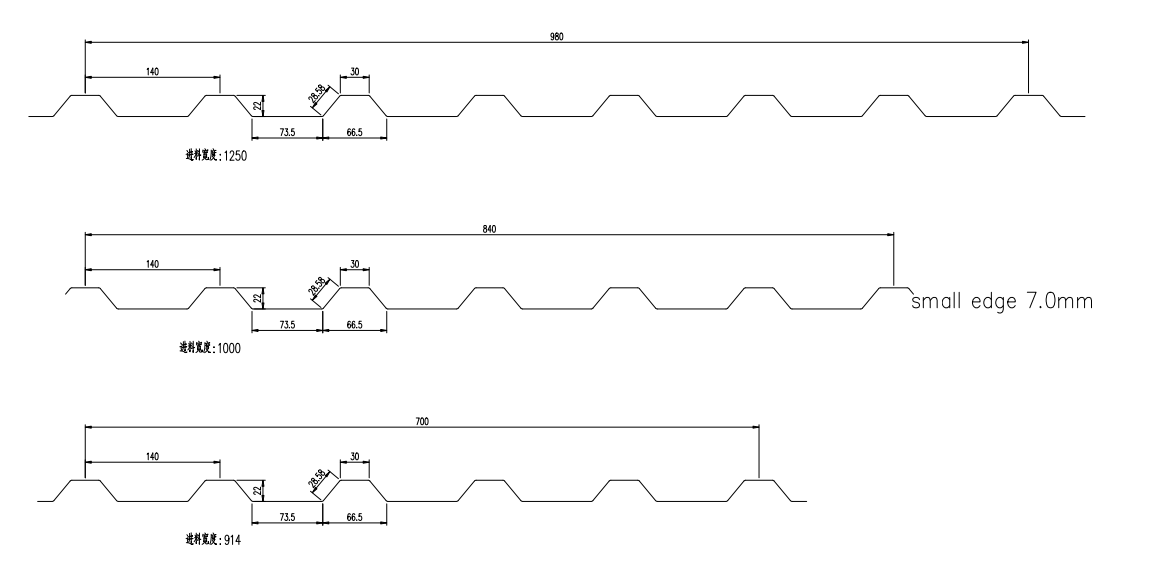

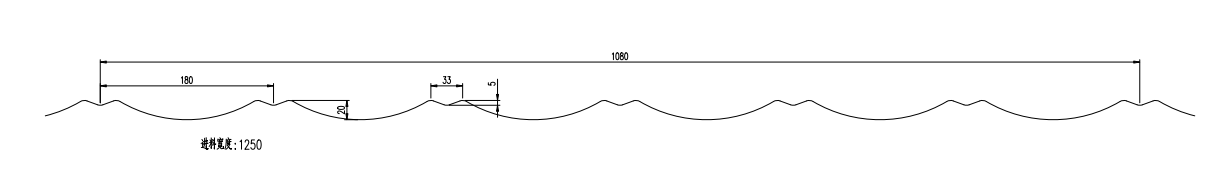

Custom Profile Drawing: (Available upon request)

Double-layer Machine

Double Layer Roll Forming Machine

Double Layer Roll Forming Machine Configuration & Packing List:

- 5T Manual Decoiler – 1 Set (Optional upgrade: Hydraulic decoiler)

- Guide Feeding Device – 1 Set (With leveling, hand cutter, support rollers, and adjustable feeding size)

- Main Roll Former – 1 Set (Chain-driven with steel welded base and up/down layers [13/16 stations])

- PLC Control Station – 1 Set (Delta PLC & Touchscreen, Schneider electrical parts, Omron encoder)

- Cutting System – 1 Set (Hydraulic cutting with Cr12 blades, ±1mm tolerance)

- Hydraulic Oil Pump Station – 1 Set (With air cooling, 5.5kW motor, and coded hydraulic connections)

- Simple Collect Table – 1 Set (Optional: Automatic stacking system)

- Spare Parts Kit – 1 Set

High-speed double-layer roofing sheet forming machine

Double Layer Roll Forming Machine Technical Specifications:

- Raw Material: GI & PPGI

- Material Thickness: 0.4–0.6 mm

- Feeding Width: Max 1250 mm

- Work Speed: 0–15 m/min

- Shaft Diameter: 80 mm (solid, 45# steel with tempering treatment)

- Rollers: Chrome-coated (0.03mm) 45# steel with internal ball bearings

- Machine Frame: 350# H steel welded with diagonal bracing

- Transmission: Chain drive (with lubrication required)

System Highlights:

Ball bearing-integrated rollers for synchronized rotation

Grooved shafts with fixed nut/cushion design to avoid loosening

Multi-order input on the control panel to avoid production interruptions

Numbered rollers and spacers for easy maintenance

Oil tubes and electrical wires clearly labeled for easy installation

High-speed double-layer roofing sheet forming machine

Hydraulic System:

Hydraulic Motor: 5.5 kW

Oil Type: 46# hydraulic oil (approx. 100L)

Cutting tolerance: ±1mm/3m

Cooling system: Air-cooled hydraulic station

High-speed double-layer roofing sheet forming machine

Simple Stacker:

Dimensions: 3m x 1m

Movement: Roller shaft assisted

Construction: Steel bar welded

High-speed double-layer roofing sheet forming machine

High-speed double-layer roofing sheet forming machine

This machine provides a compact yet powerful solution for contractors and roofing panel manufacturers looking to serve the growing U.S. steel structure and wall panel market. Our machines are custom-built to meet each client’s profile and production needs.

For more information or a custom quote, feel free to contact us!

Engineered by Zhongtuo for Precision and Surface Protection As patio and pergola structures become more

Zhongtuo Industrial Cable Tray Roll Forming Production Line Zhongtuo Cable Tray Roll Forming Machine is

Full Automatic Steel Supermarket Shelves Storage Rack Upright Pillar Roll Forming Machine Improve Warehouse Efficiency

Cable Ladder & Cable Tray Roll Forming Machine High-Efficiency Steel Side Rail Forming Machine for

STAY IN THE LOOP