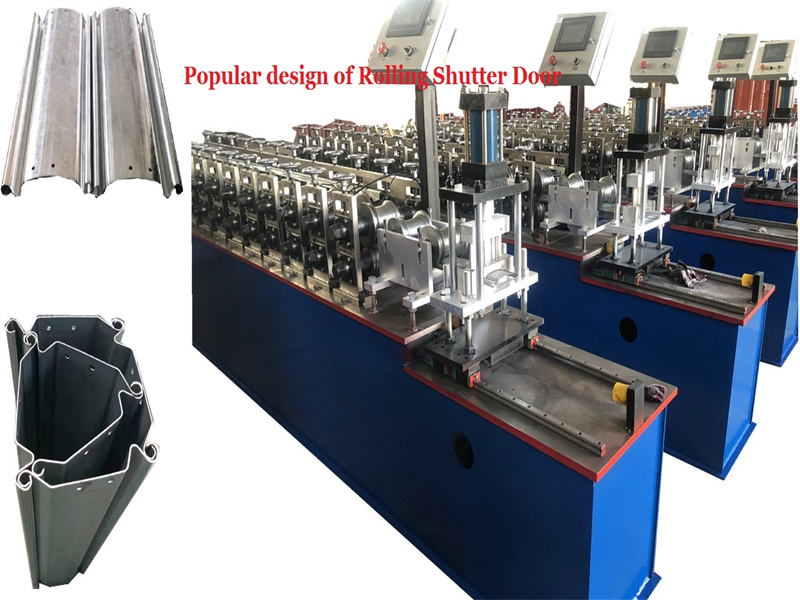

Popular Rolling Shutter Machine Design for Algeria

Rolling shutters and grilles need minimal headroom above the structure’s opening, rolling up neatly behind the lintel without taking up valuable hall space on the sides or at the ceiling. We offer a variety of roll forming machines tailored for different shutter doors, and many of our rolling shutter forming machines have been exported to numerous countries. If you have your door design, simply share your drawing with us, and our engineers can offer tailored advice. We’re ready to provide professional recommendations if you’re working on a new project.

Key Features of the Popular Rolling Shutter Machine Design for Algeria:

- Fully automated and PLC-controlled, with a forming speed of up to 25 meters per minute.

- The machine frame adopts a pillar design, giving it an elegant appearance and enhanced durability while minimizing rusting issues.

- Offers a competitive price without compromising on quality, one of the reasons for its widespread popularity.

- Uses GCr12 steel for rollers, ensuring a long service life.

- Compact PLC control box that saves space.

- Overall small and intelligent design.

Below are some technical specifications:

| No. | Item | Specification |

| 1 | Material to be formed | GI, AI |

| 2 | Operation | Automatic |

| 3 | Voltage | 380V 60Hz 3Phase (or as required) |

| 4 | Sheet thickness (mm) | 0.8-1.2mm |

| 5 | Material width (mm) | As per your requirement |

| 6 | Effective cover width | As per your design |

| 7 | Machine size (L×W×H) | 5000mm × 800mm × 1400mm |

| 8 | Speed | 8-15m/min |

| 9 | Shaft diameter | 40mm |

| 10 | Machine weight | 3000-3500kg |

| 11 | Roller material | C45 steel, quenched and chromed |

| 12 | Motor brand | Siemens or Guomao |

| 13 | PLC brand | Siemens, Delta, or Mitsubishi |

| 14 | Total power (kW) | 8kW |

| 15 | Hydraulic system power | 4kW |

| 16 | Main forming the core power | 4kW |

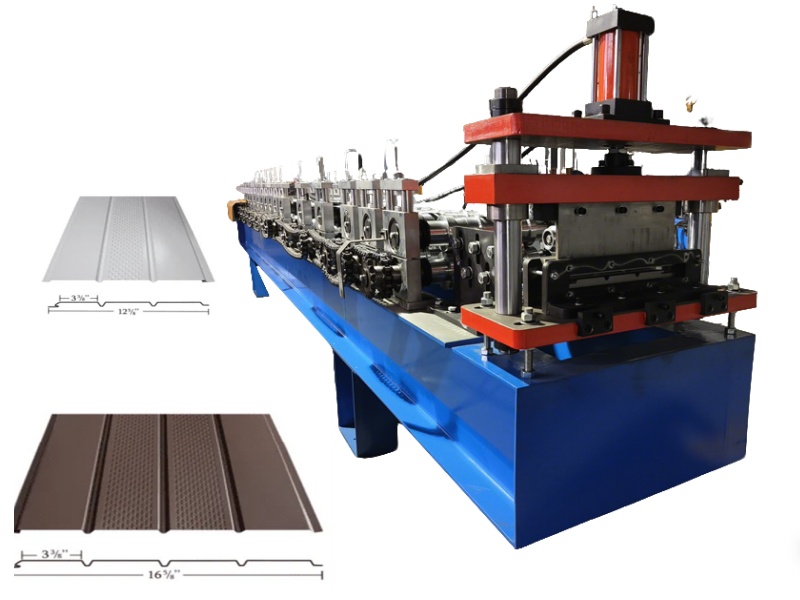

Some sample images of rolling shutters we’ve manufactured:

Additional tube components we can supply for rolling shutters include:

- Guardrails

- Bottom rolling shutter parts

- Octagonal tubes

- Protective covers

All these components can be customized according to the specific shutter design. Our forming machine design can also be tailored for elements such as mold frames, middle plate frames, and more. You can choose among hydraulic shearing, disc shearing, or flying saw cutting systems for cutting options.

Container house frame making machine Australian specification standards shipping living container house frame making machine is

Specification Standards Shipping Living Container House Frame Making Machine The Australian specification standards shipping living

Stainless Steel & Aluminum Door Frame Making Machine The stainless steel and aluminum door frame

The ZTRFM Soffit Panel Roll Forming Machine is engineered for manufacturers who require fast, stable,

STAY IN THE LOOP