Kliplock Roll Forming Machine by ZTRFM

The Kliplock Roll Forming Machine, also known as the Klip-lok or Cliplock roll former, is expertly engineered to manufacture strong, corrugated Kliplock profiles for roofing and wall cladding. This high-efficiency system automates the entire metal sheet forming process and features a user-friendly HMI panel, making operation simple and intuitive.

FEATURES

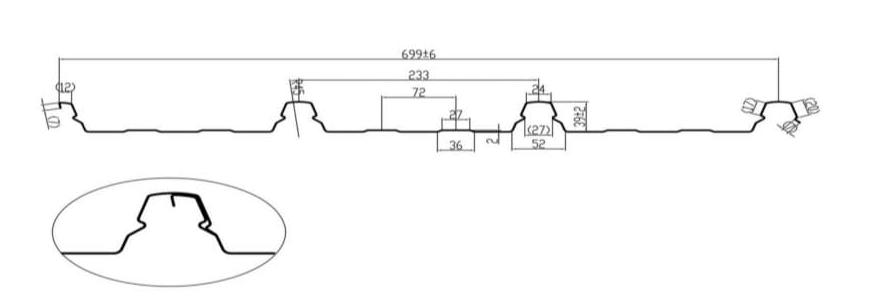

Cover width – 681 mm

Coil width – 914 mm

Section interior – 227 mm

Max height – 39 mm

Thickness – 0.36 mm, 0.42 mm & 0.5 mm

(OR)

Cover width – 705 mm

Coil width – 914 mm

Section interior – 235 mm

Max height – 37 mm

Technical Specifications of Kliplock Roll Forming Machine

Total Power: 11 kW (3-phase, 50 Hz, 380 V)

Production Speed: 18–22 meters per minute

Machine Size (L×W×H): Approximately 14.0 m × 1.6 m × 1.5 m

Machine Weight: Approximately 13 tons

Number of Roller Stations: 30–33 pairs

Material Thickness Range: 0.2–0.7 mm BMT, suitable for G400–G550 grades (galvanized, zincalume, and color-coated steel)

Material Widths: 610 mm or 914 mm

Drive System: Hydraulic

Cutting System: Hydraulic (pre-cut and profile cutting)

Control System: Fully automated with inverter, PLC, HMI, and hydraulic components

Key Features of Kliplock Roll Forming Machine

Fully automated roll forming and cutting with inverter, PLC, and HMI controls

Easy programmable length settings via touch panel

Rollers and blades made from high-grade alloy and SKD11 steel, hardened to 60–62 HRC for durability

Uses electrical and hydraulic components from trusted Japanese and German brands

Saves order history for up to 30 days

Customizable designs to meet customer specifications

Reliable performance ensured by a sturdy frame and strong power system

The Kliplock roll forming machine is perfect for producing popular profiles like Klip-lok 700 and Klip-lok 406, widely used in:

Low-slope and flat roofing

Ribbed wall cladding (vertical and horizontal)

Industrial, commercial, and residential buildings

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP