ZTRFM Teardrop 42″D x 240″H Pallet Rack Uprights Roll Forming Machine

Our ZTRFM roll forming machine is tailored to produce 42″ deep x 240″ high pallet rack uprights, ensuring consistency and reliability. This dimension is ideal for most warehouse configurations and aligns with the standard teardrop design.

Popular Pallet Rack Frames

– Steel King pallet rack frame

– Ridg-U-Rak Teardrop 42″D x 240″H Pallet Rack Uprights:

– Frame depth: 42″ (front to back)

– Frame height: 240″ (20′)

– 5″ x 6″ base plate

– Load capacity: 25,100 lbs @ 48″ vertical beam spacing

– Vista Green finish

The 240-inch Teardrop Pallet Rack Upright is a versatile storage solution that can handle up to five—or even six, if you include the floor level—48-inch spaced storage levels per bay. With a generous 20 feet of vertical space, it really helps you maximize your warehouse’s storage potential without sacrificing the ability to access items easily. Plus, the teardrop punch holes, spaced every 2 inches, make it simple to adjust shelf levels as your needs change. The support channels and footplates, complete with offset anchors, add an extra layer of safety and structural strength. Despite its impressive size, this rack can still ship efficiently throughout the U.S., making it a great choice for any warehouse looking to boost storage without the headaches.

Applications and Benefits of Teardrop Pallet Rack Upright Machine

Our Storage Racks Roll Forming Machine is built to produce top-notch teardrop pallet rack uprights that are perfect for warehouses and distribution centers. These racks help keep everything safe, organized, and running smoothly, which makes it easier to manage your inventory and get products where they need to go.

Here’s what makes these racks so valuable:

Better inventory flow and organization

Faster, easier access to stored goods

Improved safety and productivity in the warehouse

At ZTRFM Machinery, we take pride in building reliable, user-friendly rack forming machines that use PLC automation for fully automatic operation. Our machines are designed for accuracy, durability, and low maintenance, ensuring they’ll serve your business well for years to come.

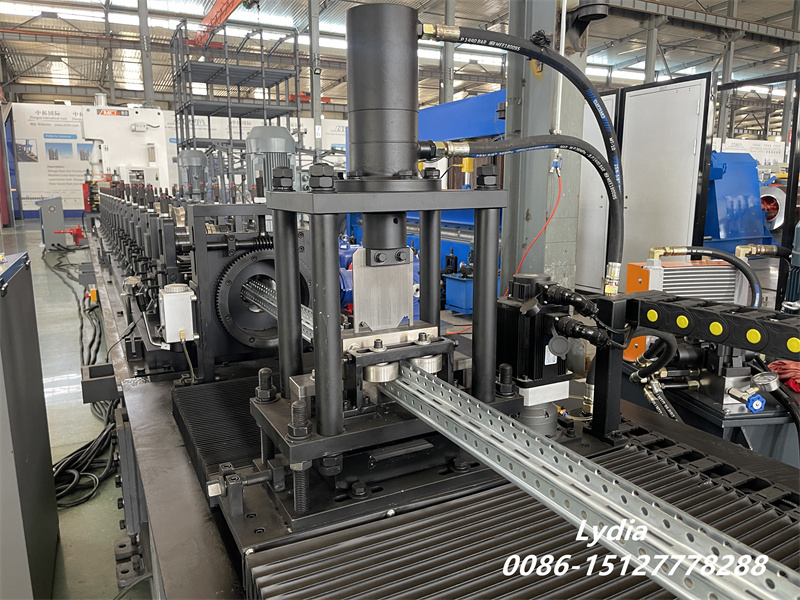

Teardrop Pallet Rack Upright Machine Typical Production Flow:

Decoiler → Punch → Roll Forming → Cutting → Run-out Table

For detailed pricing or to discuss custom configurations, please reach out to our team today.

Stainless Steel & Aluminum Door Frame Making Machine The stainless steel and aluminum door frame

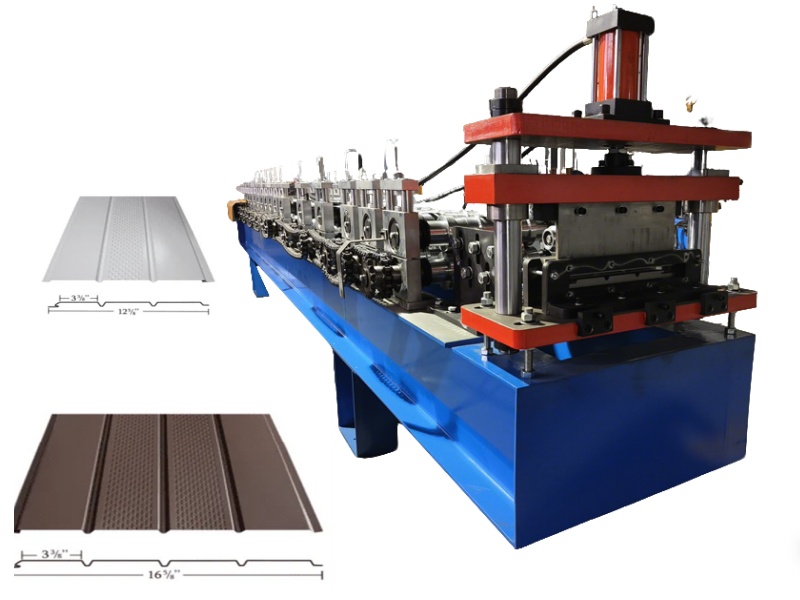

The ZTRFM Soffit Panel Roll Forming Machine is engineered for manufacturers who require fast, stable,

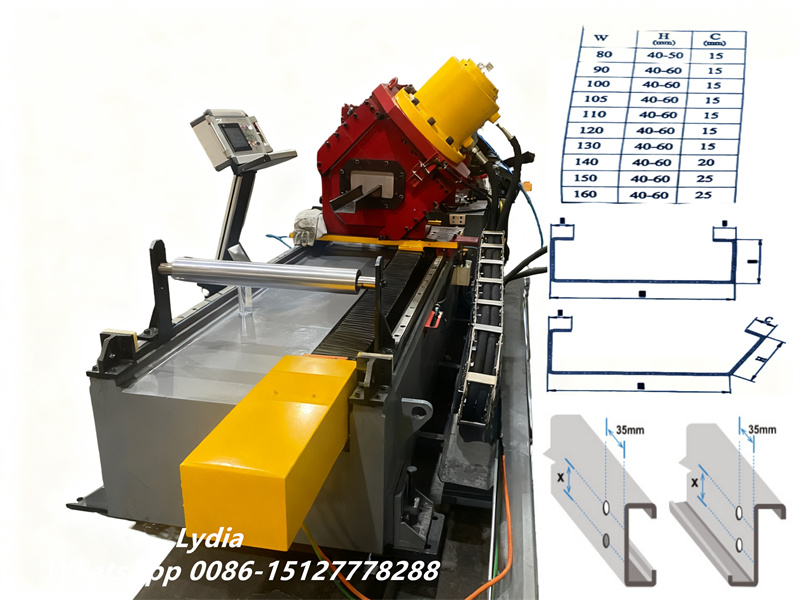

Cee & Zee Eave Struts Roll Forming Machine for Metal Buildings High-Performance Purlin Mill In

We are pleased to announce the successful delivery of our high-performance double-layer trapezoidal RIB metal

STAY IN THE LOOP