Oil canning is a universal and common visual phenomenon in the metal roofing and cladding , it will appear wavy or distort ,resembling a ripple or bulge.

oil canning of appearance on the wall panel

it’s a common characteristic in the light-gauge ,cold-formed metal products,and especially with broad ,flat areas. definitely the forming effect of the machine will directly decide the degree of appearance of the oil canning. but except the machine , it also has some other sources from other aspect.

Adding some kinds of structure to your panel and more specifically we will discuss what is the functions on of different types of structures .

First, the primary reason for incorporating structural elements into your panel is to eliminate oil canning entirely or at the very least reduce its visual prominence. Importantly, adding such structure does not incur additional costs nor does it alter the panel’s fundamental aesthetic appearance.to a perspective of machine , the more flat panel the more simple to forming the outcome, on the opposite ,the more rib , the requirement of precise to machine is more higher .

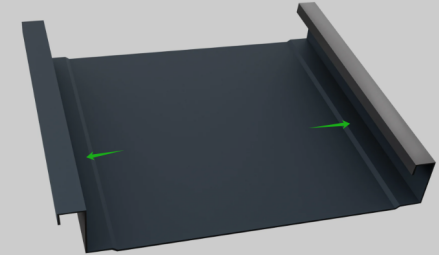

The first type of structural design is referred to as clip relief, which is strategically placed along the outer vertical leg of the panel.

clip relief on two sides

One of the standout advantages of clip relief is its near-invisibility: the vast majority of the panel remains perfectly flat, with only a tiny, discrete area featuring a subtle indentation. This slight indentation is specifically engineered to align with the panel clip, serving a dual purpose: it significantly diminishes the likelihood of oil canning while remaining visually unobtrusive. From ground level, in particular, this indentation is almost entirely imperceptible, as it occupies such a minuscule section of the panel’s surface. This combination of functionality and subtlety makes clip relief a win-win solution, which is why it is a standard feature in all Western State Metal Roofing snap-lock panels.

While the addition of structural elements is a proven method to decrease oil canning, an interesting reality is that 80 to 90 percent of the projects we sell include no structural additions beyond clip relief. This is largely driven by consumer preference: most individuals favor the sleek, unadorned look of a flat panel over designs with visible structural features.

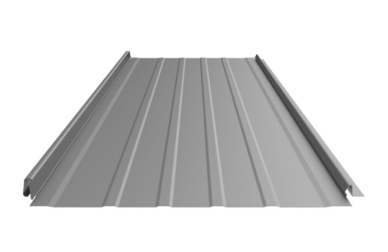

When structural elements are included beyond clip relief, the vast majority of panels feature what are known as striations.

striation rib

those striations are small, wave-like indentations that span the entire surface of the panel. Their primary advantage lies in their full-panel coverage: if minor oil canning were to occur, it would be effectively camouflaged by the striation pattern. Up close, these indentations may appear relatively pronounced, but when viewed from ground level up to the roof, their visual impact is far more subdued than what a close-up inspection would suggest.

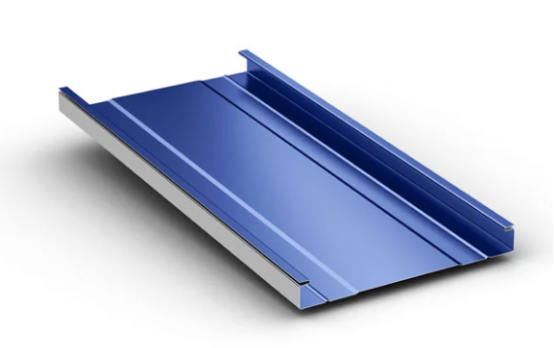

Another structural option is the stiffening rib, which is defined as a 1-inch-wide, slightly raised indentation that runs in evenly spaced intervals across the panel.

stiffening rib

Unlike striations, stiffening ribs do not cover the entire panel surface. While they are highly effective at minimizing oil canning, a notable drawback is that any subsequent oil canning or damage—such as dents caused by hail—will be more noticeable on a panel with stiffening ribs than on one with full-coverage striations.

The final structural type is the pencil rib, which shares the same set of advantages and disadvantages as stiffening ribs. The key distinction lies in its size and visibility: pencil ribs are significantly smaller and far less noticeable, offering a more understated structural solution.

pencil rib

In conclusion, the core objective of adding structure to metal panels is to mitigate the risk of oil canning.

Notably, there is no price differential associated with these structural options, nor do they impact the panel’s engineering performance, lead times, or overall functionality.

The four available structural designs are as follows:

1 Clip relief, which is minimally visible and standard on all our panels;

2 Striations, the wave-like full-coverage indentations;

3 Stiffening ribs, the 1-inch-wide spaced indentations;

4 Pencil ribs, the smaller, more discreet counterpart to stiffening ribs.

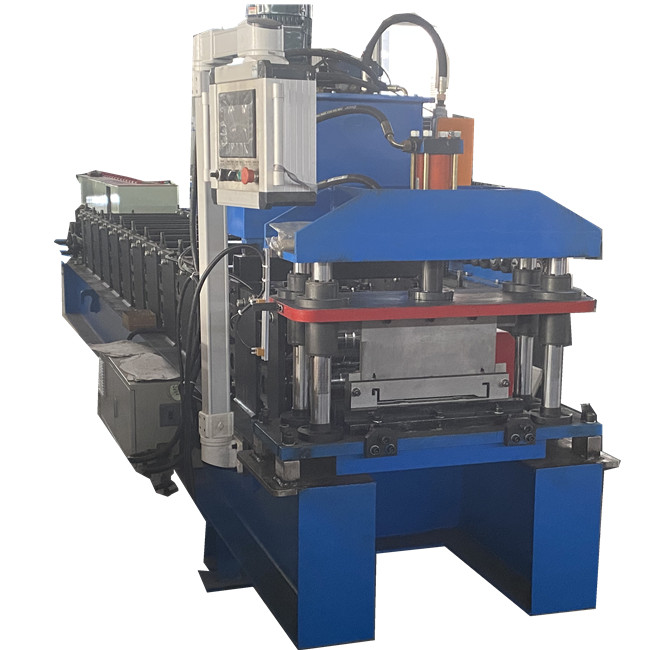

To effectively implement these structural designs and ensure precise, high-quality panel fabrication, Zhongtuo’s Standing Seam Roll Forming Machine is an ideal solution.

Designed for versatility and durability, this machine excels in forming panels with features like clip relief, striations, stiffening ribs, and pencil ribs, while maintaining

the flat-panel aesthetics or structured patterns required for different projects.

Cangzhou zhongtuo has over 20 years of experience as a manufacturer that focuses on the production of metal roofing machine for metal roofing and house systems.

We’ve helped hundreds (if not thousands) of contractors, manufacturers, with their standing seam metal roofing projects. We’re here to answer your questions.

Contact one of our knowledgeable, experienced, and helpful metal roofing specialists today!

Advantages of Floor Deck Roll Forming Machine When it comes to modern construction projects, Floor

Full-Automatic T18/T35 IBR Roofing Sheet Roll Forming System with Dual-Layer Capability This advanced roll forming

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

STAY IN THE LOOP