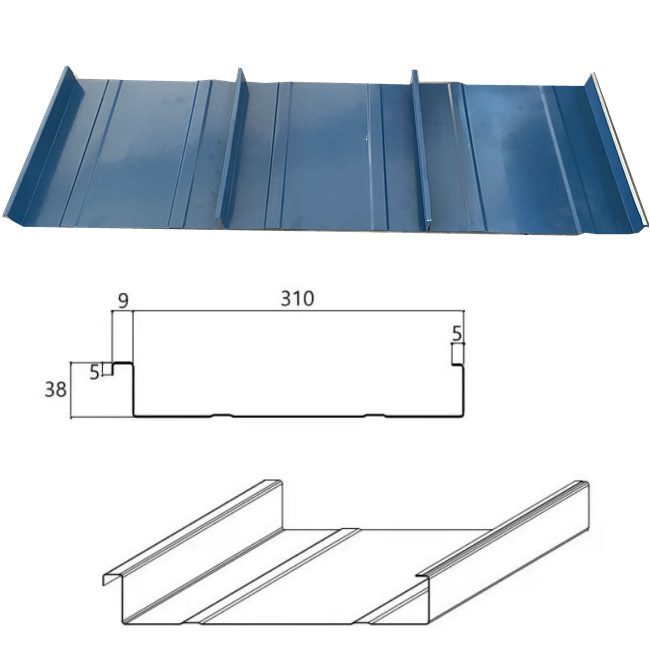

About the 310 Profile Standing Seam Panel Machine

Design: Features a concealed fastener system with interlocking seams, enhancing both aesthetics and weather resistance.

Locking Systems:

– Single-lock: A one-step seaming operation.

– Double-lock: Two passes of the seamer for added strength and security.

Benefits of Standing Seam Panel Machine:

– Eliminates the need for expansion joints.

– Reduces the risk of water infiltration due to the absence of exposed fasteners.

– Provides enhanced wind resistance.

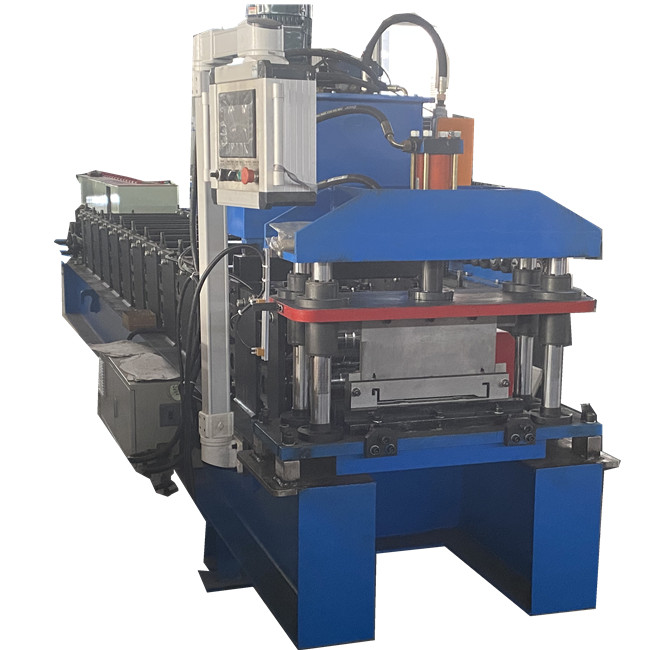

ZTRFM 310 Profile Standing Seam Roll Forming Machine

ZTRFM offers a fully automated roll-forming line designed to produce 310-profile standing seam panels efficiently:

Specifications of Standing Seam Machine:

– Panel Height: 38mm

– Panel Width: Adjustable between 500–650mm

– Material Thickness: 0.3–0.8mm (PPGI, PPGL, GI, GL)

– Production Speed: Up to 20 meters per minute

– Cutting Type: Hydraulic shear with ±1mm accuracy

– Control System: PLC (Delta)

Features of Standing Seam Machine :

– Equipped with 12 forming stations using 45# steel rollers.

– Hydraulic cutting with GCr12MoV blades.

– Supports various materials, including pre-painted and bare coils.

– Compact design suitable for both workshop and on-site production.

How Standing Seam Machine Operates

- Coil Unloading: Pre‑painted or bare coils (HR, CR, G/Z) are loaded onto the decoiler.

- Feeding: The metal strip is guided into a leveler, then into the roll‑forming stands.

- Forming: Twelve stations of 45#‑steel rollers progressively bend the strip into the 310 profile with its 38 mm high rib.

- Cutting: A hydraulic shear (Cr12 blades, ±1 mm accuracy) slices each panel at the desired length.

- Seaming (off‑line): Panels are locked together on‑site using a locker machine or hand tools to close the standing seams.

Key Technical Data of Standing Seam Machine

| Feature | Specification |

| Material Thickness | 0.50–0.80 mm |

| Coil Width (approx.) | 607 mm |

| Roller Stations | 12 stands |

| Roller & Shaft Steel | 45# |

| Shaft Diameter | 60 mm |

| Middle Frame Plate | 20 mm thick |

| Transmission | 1″ chain drive |

| Forming Speed | Up to 20 m/min |

| Main Motors | Two × 3 kW |

| Hydraulic Power Unit | 4 kW motor, oil type #46 |

| Trim Shear Accuracy | ±1 mm |

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP