Efficient 24‑28 Cross Ceiling T‑Grid Roll Forming Machine for Lightweight Suspended Ceilings

The 24‑28 Cross Ceiling T‑Grid Roll Forming Machine is designed to produce 24 × 28 mm T‑grid sections with exceptional speed and consistency. With a CE‑certified build and a robust H‑frame, this model delivers up to 20 m/min forming speed and precise hydraulic cutting, making it ideal for standard 600 × 600 mm gypsum board ceilings.

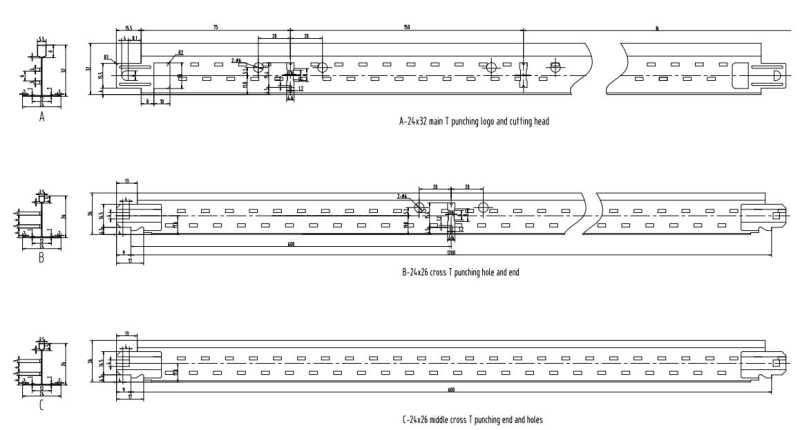

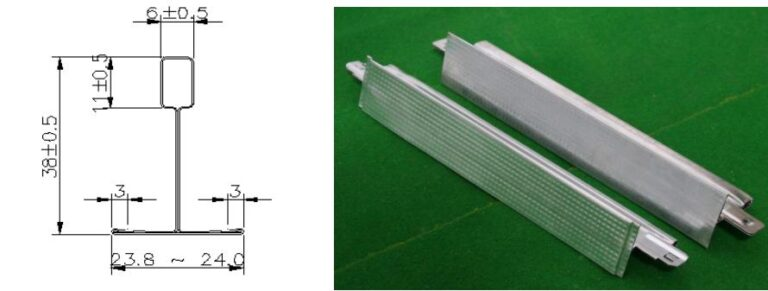

The Drawing Profile Ceiling T‑Grid Roll Forming Machine:

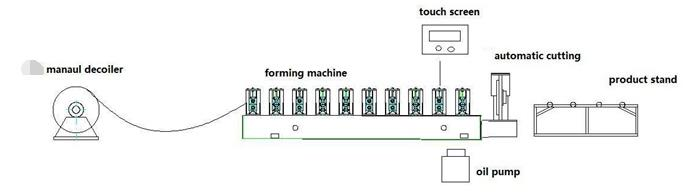

Streamlined Ceiling T‑Grid Roll Forming Machine Process Flow

- Manual Decoiling – Load galvanized coil onto the 1.5 T manual stand and expand to feed entry.

- Material Guiding – Precise side guides align the strip for uniform forming.

- Sequential Roll Forming – Metal passes through 16 stations, gradually shaping the T‑grid profile.

- In‑Line Punching & Cutting

Separate hydraulic punch head and shear cutting. Continuous punching and cutting on a tracked system.

- Run‑Out Table – Finished T‑grid pieces stack neatly for inspection and packaging.

Rugged Ceiling T‑Grid Roll Forming Machine Features

– Memorial Arch Frame ensures rigidity.

– High-Grade Materials: GCr12MoV rollers, 45# steel shafts.

– Delta PLC: Multilingual 5.7” touchscreen.

– Hydraulic Station: Air-cooled, high-pressure pump.

– Quick Setup: Manual decoiler, slide-in roll stations.

– Easy Maintenance: Enclosed drive, color-coded wiring.

Tailored Ceiling T‑Grid Roll Forming Machine Solutions for Every Project

– Standard 600 × 600 mm Ceilings with 24‑28 T‑grid.

– Reinforced Main Runners using 24‑38 T‑grid.

– Compact footprint for remote or retrofit job sites.

24‑38 Main Ceiling T‑Grid Roll Forming Machine Technical Specifications

Here is a comparison of the technical specifications:

| Specification | 24 28 Cross T Machine | 24 38 Main T Machine |

| Profile Size (mm) | 24 × 28 | 24 × 38 |

| Roll Stations | 16 | 16 |

| Shaft Diameter (mm) | 40 | 40 |

| Roller Material | GCr12MoV | GCr12MoV |

| Frame Type | Memorial arch frame | Memorial arch frame |

| Forming Speed (m/min) | 10–20 | Up to 20 |

| Main Motor (kW) | 5.5 | 5.5 |

| Hydraulic Motor (kW) | 3 | 5.5 |

| Control System | Delta PLC, 5.7″ touchscreen (EN/CN) | Delta PLC, 5.7″ touchscreen (EN/CN) |

| Decoiler Capacity | 1.5 T manual | 1.5 T manual |

| Cut & Punch | Separate hydraulic punch + cut | Continuous punch & cut with track |

| Footprint (mm) | 6,200 × 850 × 1,500 | 6,500 × 850 × 1,500 |

| Weight (approx.) | 3.5 T | 4.8 T |

Engineered by Zhongtuo for Precision and Surface Protection As patio and pergola structures become more

Zhongtuo Industrial Cable Tray Roll Forming Production Line Zhongtuo Cable Tray Roll Forming Machine is

Full Automatic Steel Supermarket Shelves Storage Rack Upright Pillar Roll Forming Machine Improve Warehouse Efficiency

Cable Ladder & Cable Tray Roll Forming Machine High-Efficiency Steel Side Rail Forming Machine for

STAY IN THE LOOP