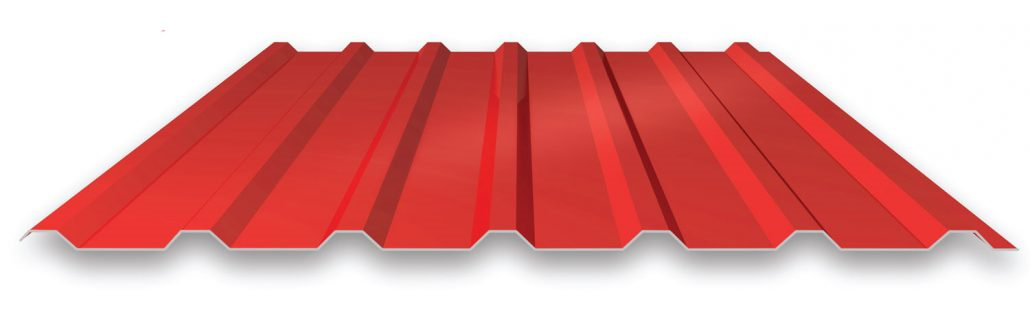

M-Panel Description

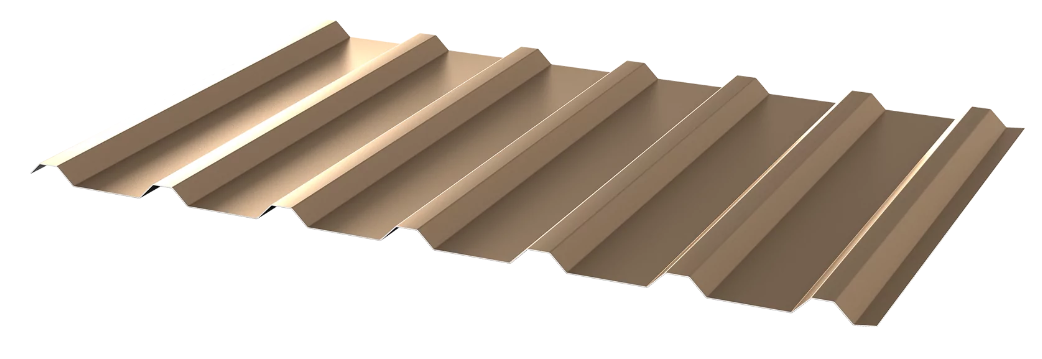

The M-Panel is a 36-inch wide, exposed fastened panel designed for versatile use in both vertical and horizontal installations. This adaptable corrugated panel can be mounted on either open framing or a solid substrate, offering limitless design options. It is suitable for a variety of applications, including walls, interior liners, soffits, and roofs.

The M-Panel is the latest addition to Martin Metal’s range of profiles, crafted using state-of-the-art roll-forming technology from Bradbury. It offers the distinctive appearance of a Standing Seam profile, while its installation process is akin to that of the G-Rib. Though this panel is primarily designed for roofing applications, it is also suitable for use on sidewalls.

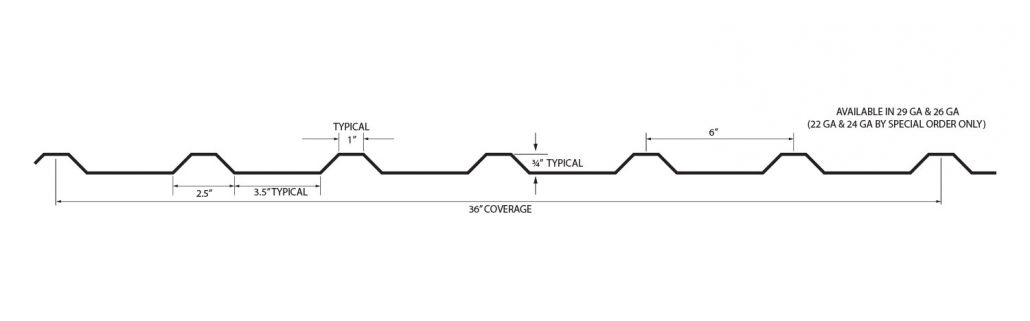

Profile drawing:

Panel Specifications For M-panel Roofing Machine

- Applications: Roofing Panel, Wall Panel

- Fastener: Exposed Fastener

- Coverage: 36″ Coverage

- Rib Height: 3/4″

- Exposed fastener panel for soffit and wall applications

- Suitable for solid deck or open framing

- 12″ rib spacing

- 3/4″ rib height

- Cut to the 1/2″ inch

The M-Panel Roofing Machine offers several advantages for panel specifications:

- Versatility:Capable of producing M-panels that can be used for a variety of applications, such as roofing, walls, interior liners, and soffits, making it a versatile choice for different construction needs.

- Customization:Allows for customization of panel lengths and profiles, which can be tailored to specific project requirements.

- Efficiency:The machine enables quick and efficient production of panels, reducing labor costs and project timelines.

- Consistency:Provides high-quality and uniform panels, ensuring consistency and reliability in the final installation.

- Durability:The panels produced by the M-Panel Roofing Machine are robust and designed to withstand various weather conditions, contributing to long-lasting performance.

- Cost-Effectiveness:Helps in reducing material wastage by producing panels on-demand and in precise lengths, which can lead to cost savings.

The technical specifications of the M-panel Roofing Machine:

| NO | Name | Specifications |

| 1 | Raw material | Galvanized steel and Pre-painted steel |

| 2 | Raw material thickness | 0.3-0.8mm |

| 3 | Decoiler | 5T Hydraulic decoiler(Different capacity for option,manual one for option) |

| 4 | Roller station | 18 stations |

| 5 | Roller material | 45# steel with quenched treatment |

| 6 | Shaft diameter | 80mm |

| 7 | Shaft material | 45# steel with tempered |

| 8 | Transmission | by gear box transmission |

| 9 | Motor power | 5.5kw motor |

| 10 | Machine frame | 400H steel welded |

| 11 | Cutting type | Hydraulic cutting |

| 12 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr 12 High Grade Steel |

| 15 | Cutting tolerance | +/-1mm |

| 16 | Control system | PLC |

| 17 | Brand | PLC:Delta/Siemens/Mitsubishi

Touch screen:Delta/Siemens/Mitsubishi Encoder:Omron |

Engineered by Zhongtuo for Precision and Surface Protection As patio and pergola structures become more

Zhongtuo Industrial Cable Tray Roll Forming Production Line Zhongtuo Cable Tray Roll Forming Machine is

Full Automatic Steel Supermarket Shelves Storage Rack Upright Pillar Roll Forming Machine Improve Warehouse Efficiency

Cable Ladder & Cable Tray Roll Forming Machine High-Efficiency Steel Side Rail Forming Machine for

STAY IN THE LOOP