Perforated metal mesh, also known as perforated sheet, stamping plates, or perforated screen, is created by punching various hole patterns into metal panels. It is widely used across architectural, industrial, and decorative applications.

How to Choose the Right Machine for Perforated Metal Production?

Selecting the proper CNC punching machine depends on several key factors:

- Sheet Thickness – Choose a machine that matches your material thickness.

- Hole Shape – Round, square, slotted, or customized shapes.

- Hole Size & Spacing – Consider the open area percentage (% Open Area) for airflow, filtration, or aesthetics.

- Sheet Format – Decide whether you need standard sheet sizes, custom cut-to-size, or recoil processing.

What is CNC Punching?

CNC punching (Computer Numerically Controlled punching) is a precise and automated sheet metal fabrication process. A CNC sheet metal punch can quickly and accurately stamp a wide variety of shapes into different types of metal sheets based on digital programming.

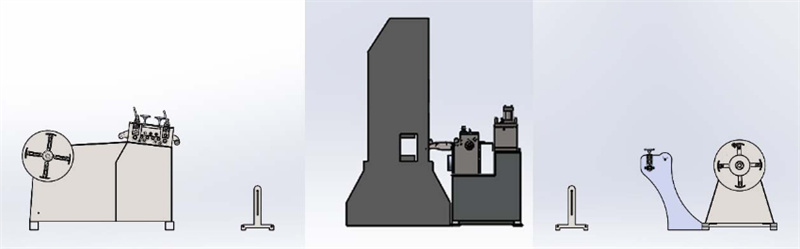

5 Ton CNC Punching Machine Structure & Features:

- High Precision CNC Punching Machine – Developed by Yangli Group, designed for punching, blanking, cutting, light stretching, and forming operations.

- C-Type Steel Welded Frame – High rigidity, low deformation, and compact wide-body structure to reduce vibration and improve die and machine life.

- Six-Side Rectangular Slide Guides – Ensures precise die alignment with high motion accuracy, extending tool lifespan.

- Advanced Gear System in Oil Bath – Smooth, quiet operation with reduced shaft deflection and extended gear life.

- Simple Operation with High Accuracy – This machine offers excellent performance, energy efficiency, a user-friendly interface, and competitive pricing.

Micro Hole Perforated Metal Capability

Our CNC punching line is especially capable of producing micro hole perforated metal sheets, with hole diameters smaller than 1.0 mm, widely used in industries requiring precision, such as filtration, food processing, electronics, and chemical machinery.

✔ Micro Hole Sizes:

– CNC punching: Minimum hole size 0.4 mm–0.5 mm

– Chemical etching: Down to 0.2 mm or smaller

– Micro drilling: Hole diameter smaller than sheet thickness

✔ Supported Materials:

– Stainless steel sheet (0.1–1.0 mm)

– Carbon steel plate

– Aluminum sheet

– Brass sheet

– Other metal materials on request

✔ Production Range:

– Width: 10 mm to 1500 mm

– Length: Customizable

– Over 100 ready-made tooling molds in stock for fast delivery without custom die cost

Most micro hole sheets are designed with holes equal to material thickness (also called holes-as-thickness), suitable for demanding mechanical and filtration purposes.

Applications of Perforated Metal Sheets:

– Ventilation and air filtration systems

– Acoustic panels and sound insulation

– Industrial filters and sieves

– Decorative panels for interiors and exteriors

– Machine guards and safety enclosures

– Display panels, shelves, fencing, infill panels, and more

Contact us today for a detailed quote, technical specifications, sample testing, or a video demonstration. We are ready to support your perforated metal production needs with top-quality machines and service.

Engineered by Zhongtuo for Precision and Surface Protection As patio and pergola structures become more

Zhongtuo Industrial Cable Tray Roll Forming Production Line Zhongtuo Cable Tray Roll Forming Machine is

Full Automatic Steel Supermarket Shelves Storage Rack Upright Pillar Roll Forming Machine Improve Warehouse Efficiency

Cable Ladder & Cable Tray Roll Forming Machine High-Efficiency Steel Side Rail Forming Machine for

STAY IN THE LOOP