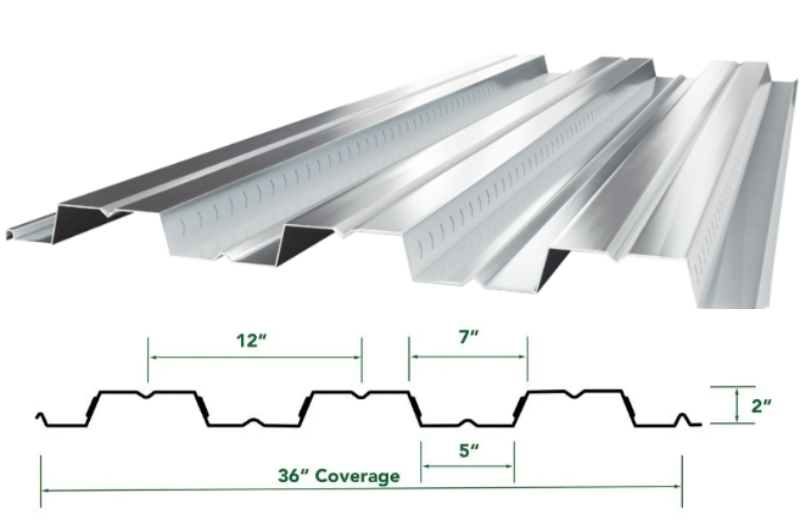

2.0″ Composite Floor Deck Roll Forming Machine Profile:

2.0″ Composite Floor Deck Machine Specifications:

2” Composite Floor Decking is Available in:

Gauges: 22, 20, 18, 16

Finishes: Galvanized G60, Galvanized G90

Cover Width: 36″

Side Lap Connections: Interlocking

Other Variations: Composite Cellular, Composite Cellular AcousticalThe machine in the below photo are the 2.0″ Composite Floor Deck machine we made before for our USA customer.

2” Composite Floor Metal Deck is reliable and easy to install choice for your metal floor decking.

Hydraulic Decoiler

Coupled with loading cart;

Cantilever arm length:1250mm

Motorized unwinding,Hydraulic expansion

Forming Tooling Mill

Feeding Guide;

Embossing roller;

24 stations of roller,Shaft φ90mm,

Motor 15KW*2Sets;

2.0″ Composite Floor Deck Roll Forming Machine

The Zhongtuo 2.0″ Composite Floor Deck Roll Forming Machine is a high-performance solution for producing composite steel decking panels used in floors and roofs of commercial and industrial buildings. Fully assembled at our Orlando, Florida factory, it includes a one-year warranty and is customized to meet specific project requirements.

Key Features

- Efficient Roll Forming: Gradually shapes steel coils into precise 2.0″ ribbed profiles for maximum structural strength.

- Material Feeding System: A reliable decoiler ensures smooth, uninterrupted operation.

- Advanced Cutting Mechanism: Flying shear technology cuts panels to the desired length without halting production.

- User-Friendly Controls: Computerized systems allow easy adjustments to dimensions, speed, and length.

- Stacking & Packaging: Automates handling for easy transport and installation.

Benefits of 2.0″ Composite Decking

- Durability: Galvanized steel ensures corrosion resistance.

- Strength: Supports heavy loads and distributes weight evenly.

- Fire Resistance: The steel-concrete combination enhances safety.

- Fast Installation: Lightweight panels reduce labor time and costs.

Widely used in warehouses, factories, and offices, this machine ensures high-precision, cost-effective production to meet the demands of modern construction projects.

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP