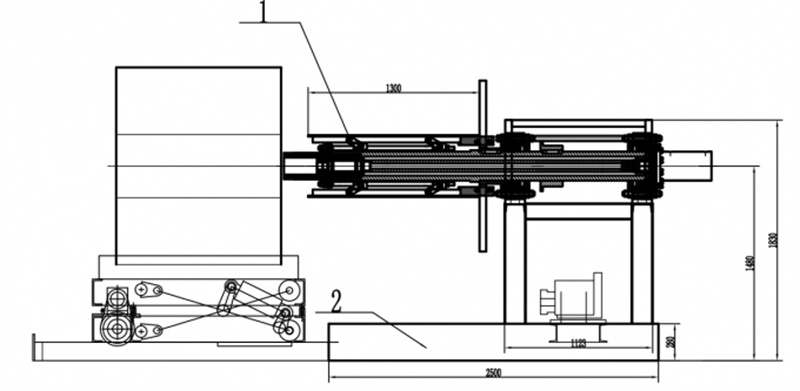

This 10-ton automatic hydraulic decoiler, equipped with a coil car, is powered by a motor and hydraulic pump, significantly reducing the need for manual labor—saving the cost of one worker.

10-Ton Automatic Hydraulic Decoiler with Coil Car

A sensor is installed between the decoiler and the roll forming machine. When the coil strip becomes tight, the sensor signals the decoiler to move forward. If the strip becomes loose, the sensor stops the decoiler, ensuring continuous, automatic adjustment. This system improves both operational convenience and production stability.

Advantages Of Zhongtuo Hydraulic Decoiler

- Premium Electrical Components

Zhongtuo hydraulic decoilers are fitted with high-quality electrical parts from the globally renowned brand SCHNEIDER, ensuring enhanced operational reliability and safety. This results in more stable equipment performance and reduces the likelihood of electrical faults during long-term use. - Pneumatic Braking System

The advanced pneumatic brake enables the decoiler to stop rotating immediately when needed, effectively preventing excess coil unwinding. Its rapid response improves safety and is especially beneficial for high-speed roll forming lines that demand faster uncoiling. The pneumatic system delivers stronger braking force, but users must connect their own air supply to operate this feature. - Coil Expanding Mechanism

A four-arm expansion structure with sliding blocks provides robust clamping strength to hold the coil securely in place. The synchronized movement of all arms prevents coil distortion during operation. Additionally, the blocks mounted on the arms are designed to accommodate coils with larger inner diameters, enhancing flexibility for different coil sizes. - Intelligent Limit Switch Arm and Roller Guide

An integrated limit switch arm enables automatic start/stop control of the decoiler based on the speed and progress of the roll forming machine, allowing for synchronized operation. The switch assembly can also be mounted on the opposite side of the decoiler for reverse feeding if required; pre-installed brackets are provided for this purpose. Moreover, guiding rollers on both sides of the frame help prevent scratching or damaging the coil edges as the material feeds out.Whenever a steel coil needs to be flattened into a steel panel, this hydraulic decoiler provides a reliable and efficient solution.

Technical Specifications Of Hydraulic Decoiler With Coil Car

| No. | Item | Specification |

| 1 | Machine Name | Hydraulic Decoiler for Steel Coil / 10T Automatic Decoiler with Coil Car |

| 2 | Overall Size | 2.8m × 1.7m × 2.0m |

| 3 | Total Weight | 3.8 Tons (including coil car) |

| 4 | Main Shaft Diameter | 200mm |

| 5 | Motor Power | 5.5kW with PM250 Steel Gear Reducer, Speed Ratio 40:17 |

| 6 | Hydraulic Pump Motor | 4kW, Lichao Brand (Shanghai) |

| 7 | Frequency Converter | 7.5kW, Sanjing Brand |

| 8 | Hydraulic Cylinder | 125mm rotary type |

| 9 | Base Frame | Constructed with 350 H-beam steel |

| 10 | Frame Material | 16mm thick steel plate |

| 11 | Maximum Coil Capacity | 10 Tons |

| 12 | Maximum Coil Width | 1250mm (customizable) |

| 13 | Coil Inner Diameter | 470–530mm (can be customized) |

| 14 | Electrical Control Box | Delta brand, Taiwan |

| 15 | Power Supply | 380V, 50Hz, 3-Phase (or as per user requirement) |

Coil Car Details

– Lifting Mechanism: Dual hydraulic cylinders, 90mm diameter, 240mm stroke

– Forward Motion: Driven by a 450-type hydraulic motor

– Discharge Panel Size: Length 1250mm, Width 1100mm

– Track Dimensions: Width 1050mm, Length 2500mm

– Car Travel Range: Vertical stroke 400mm, Horizontal stroke 2500mm

For the hydraulic decoiler we can make it to 5 ton, 7 ton 7 ton , 10 ton 15 ton 20 Ton and more, fully design according to your requirements. For more information, please contact us at any time.

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP