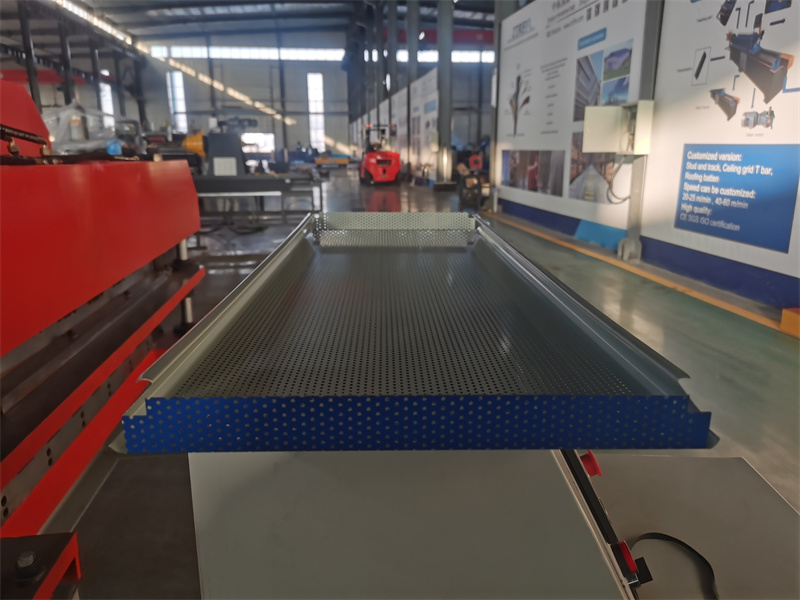

ZTRFM offers a fully automated production line for manufacturing metal 300C Panel Ceiling Machine suspended ceiling tiles and panels. This highly versatile system accommodates diverse materials, panel thicknesses, and widths (up to 2,000 mm). It efficiently produces standard panel designs like Lay-In, Clip-In, and Lay-On, and can be customized for unique requirements using materials including galvanized steel, aluminum, stainless steel, titanium, copper, or brass.

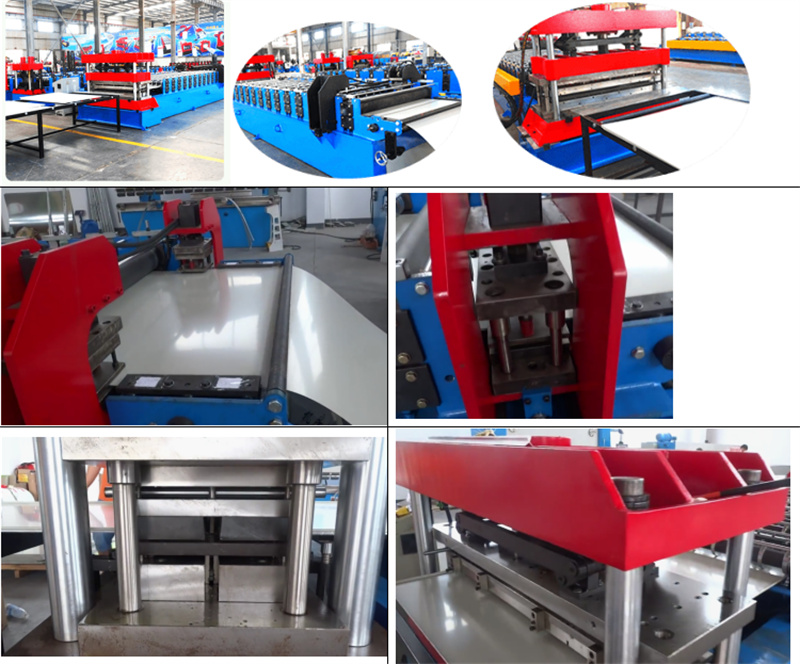

Integrated 300C Panel Ceiling Machine Production Modules:

The line features seamlessly integrated modules:

- Material Handling:Decoiler, loading cart, straightener, and servo feeder for precise raw material feeding.

- Perforation:Customizable press with bespoke dies for exact hole patterns.

- Cutting: Unit for precise panel length cutting.

- Transfer & Optional Processing:Conveyor system (with optional secondary press) for panel transfer and additional bending/notching.

- Edge Finishing: Dedicated press for final shaping and edge notching/bending.

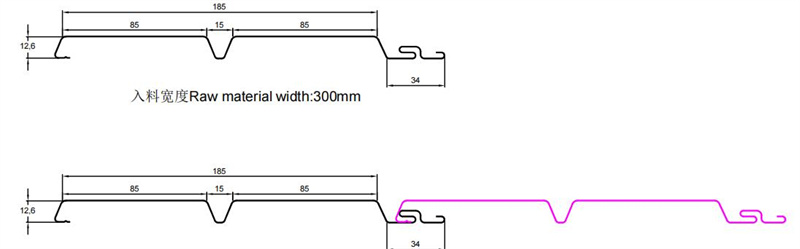

300C panel ceiling machine

Workflow Of 300C Panel Ceiling Machine Production:

Material flows through the line: Decoiler → Straightener → Servo Feeder → Perforation Press → Cutting Unit → Conveyor → Bending/Notching Press.

| Details | Parameter |

| Raw material | PPGI/GI/Full hard material |

| Material thickness | 0.3-1.0 mm |

| Material width | ≤1250 mm |

| Coil weight | ≤5 tons |

| Work type | Passive type, manual expansion |

| Loading capacity | 5 tons |

| Inner diameter | 450-550 mm (manual adjustment) |

| Coil width | 1250 mm |

| Brake system | Manual, big hand driving wheel |

| Main power | 7.5 kW |

| Roll stand | 16 |

| Roller material | 45# steel |

| Shaft diameter | 80 mm (solid shaft) |

| Machine structure | Carbon steel welded |

| Basic frame | 350# H steel welded, anti-rust |

| Transmission | Chains with cover |

| Language | English/Chinese |

| Function | Cutting length & qty control, speed adjustment |

| Feature | Control station with aviation plug |

| Work type | Hydraulic cutting |

| Motor power | 5.5 kW |

| Cutter material | GB-Cr12 |

| Conveyor length | 3 meters |

Applications:

This production line is perfectly suited for manufacturing durable and aesthetically pleasing suspended ceilings in demanding environments such as:

- Metro Stations

- Airports

- Shopping Malls

- Hospitals

- Office Buildings

- Other Commercial & Public Buildings

Metal ceilings are preferred for their durability, low maintenance, fire resistance, and modern appearance.

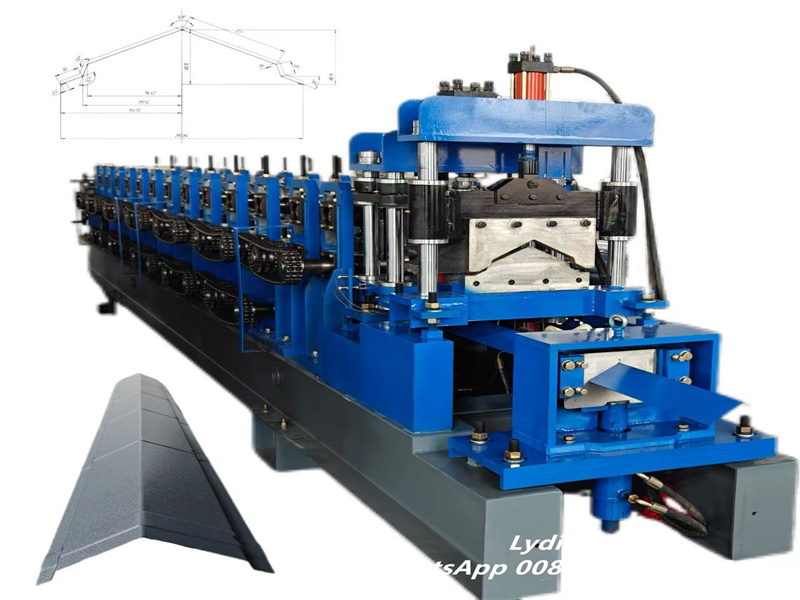

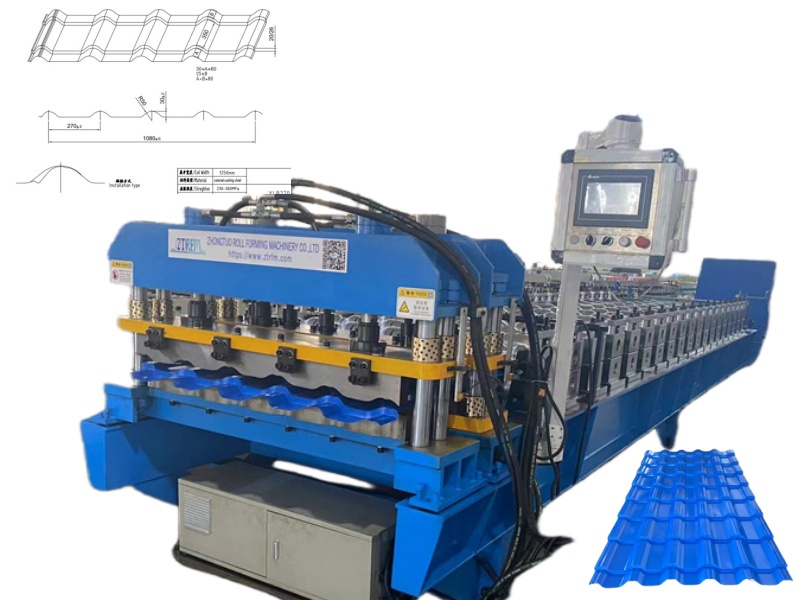

Double-Layer Ridge Capping Roll Forming Machine In modern roofing construction, ridge caps play a critical

Mangalore Tile Profile Sheet Roll Forming Machine Overview of Mangalore Tile Profile Sheet Roll Forming

Metal Ridge Capping Making Roll Forming Machine Efficient, Accurate & Worry-Free Roofing Profile Machine The

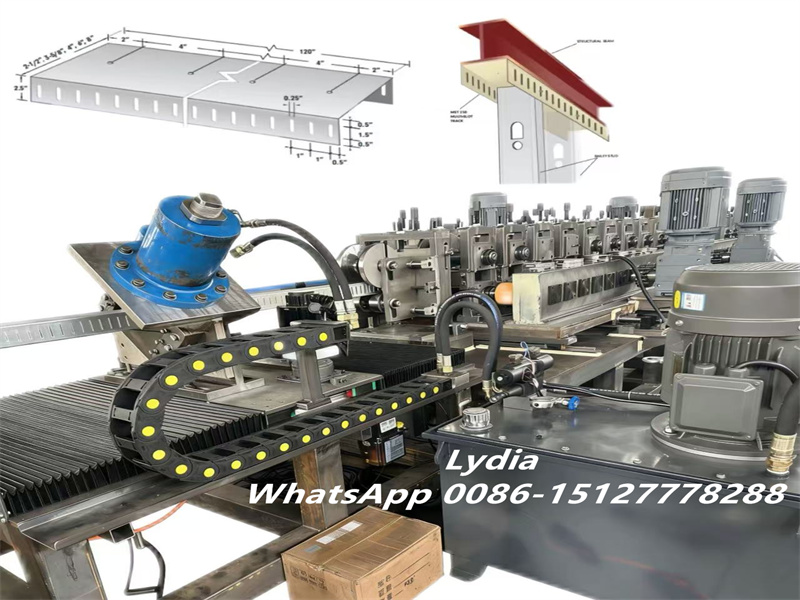

C Channel Light Steel Keel Stud and Track Roll Forming Machine High-Precision Drywall CU/CW Profile

STAY IN THE LOOP