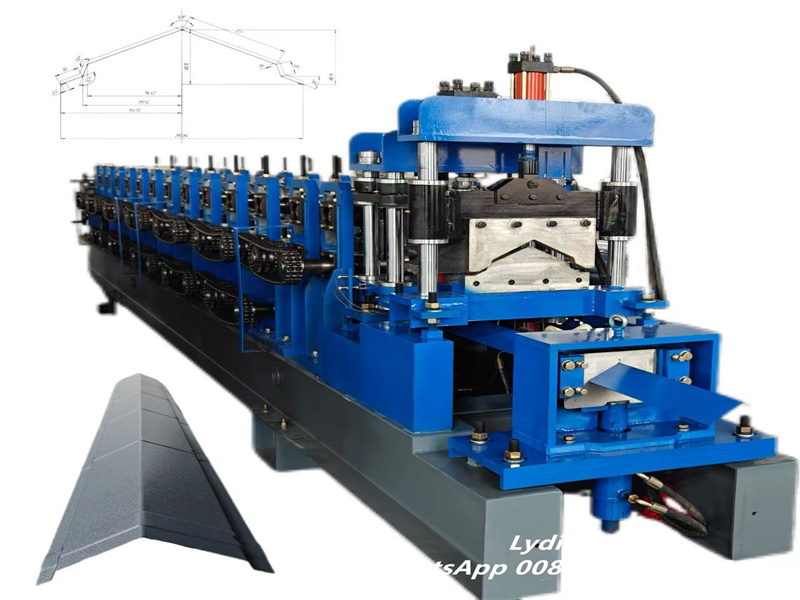

Zhongtuo High-Speed Picket Fence PPGI Cold Roll Forming Machine for the Russian Market

The Picket Fence PPGI Cold Roll Forming Machine is a high-performance production line specially designed for manufacturing decorative metal picket fences used in residential, industrial, and public areas. With 15 roller stations and a forming speed up to 25 meters per minute, this machine combines precision, stability, and durability to meet large-scale production needs in the Russian metal fence industry.

fence roll forming machine

Made from PPGI (Pre-painted Galvanized Iron), the final picket fence panels are known for their anti-corrosion performance, smooth surface finish, and long-lasting beauty—ideal for outdoor environments.

fence roll forming machine

Machine Configuration of Dura Fence & Palisade Panel Roll Forming Machine

| Item | Specification |

|---|---|

| Material | PPGI (Pre-painted Galvanized Steel) |

| Thickness Range | 0.4–0.8 mm |

| Roller Stations | 15 stations |

| Roller Material | GCr12 / Cr12Mov, precision machined and hardened |

| Shaft Diameter | 60 mm (45# steel, quenched and tempered) |

| Forming Speed | 15–25 m/min |

| Transmission | Gear drive |

| Motor Power | 3 kW |

| Voltage | 380V, 50Hz, 3Phase |

| Frame Type | Molding frame, thickness 25–35 mm |

| Cutting System | Hydraulic shearing with lace-cut and punching holes |

| Control System | PLC control with touch screen (±0.5 mm cutting accuracy) |

| Decoiler | Optional hydraulic or manual type |

| Application | Decorative metal fence, outdoor security fencing, residential and garden boundary fencing |

Key Features and Advantages of Steel Fence Making Machine

The Steel Fence Making Machine delivers a perfect combination of speed, precision, and durability for large-scale metal fence production. Below are its key advantages:

- High Speed and Efficiency – It produces up to 25 meters per minute, allowing manufacturers to complete orders quickly and maintain continuous production.

- Smooth Surface Forming – Each roller is precision-machined and chrome-plated, which keeps the metal surface perfectly smooth and free from scratches.

- Strong Frame Structure – With a 25–35 mm thick molding frame, the machine runs stably and minimizes vibration, even under heavy-duty operation.

- Hydraulic Lace Cutting and Punching – It delivers clean lace edges and accurate punching holes, making installation easier and enhancing the fence’s appearance.

- Fully Automatic PLC Control – Operators can easily set the length, quantity, and cutting parameters. The system ensures ±0.5 mm cutting accuracy for every piece.

- Durable Roller Material – The GCr12Mov steel rollers offer outstanding wear resistance, extending the machine’s service life.

- Customizable Design Options – You can tailor fence profiles and punching patterns to meet Russian, European, or American standards. This flexibility helps meet diverse market demands.

Overall, this Steel Fence Roll Forming Machine stands out for its automation, high precision, and superior surface quality, making it a reliable choice for modern metal fence production lines.

fence roll forming machine

Applications of the metal picket fence roll forming machine

The metal picket fence roll forming machine is widely used in:

- Residential fencing for gardens and private properties

- Industrial fencing for factories and warehouses

- Public facilities such as parks and schools

- Decorative fencing for commercial spaces and villas

Its robust design and elegant finish make it a preferred solution for both security and aesthetics.

fence roll forming machine

With the growing demand for durable and decorative fencing in the Russian market, the Picket Fence PPGI Cold Roll Forming Machine stands out as a cost-effective, reliable, and automated solution for modern fence production.

If you’re looking for a professional metal fence roll forming line with high speed, strong precision, and long service life, this machine is your ideal investment.

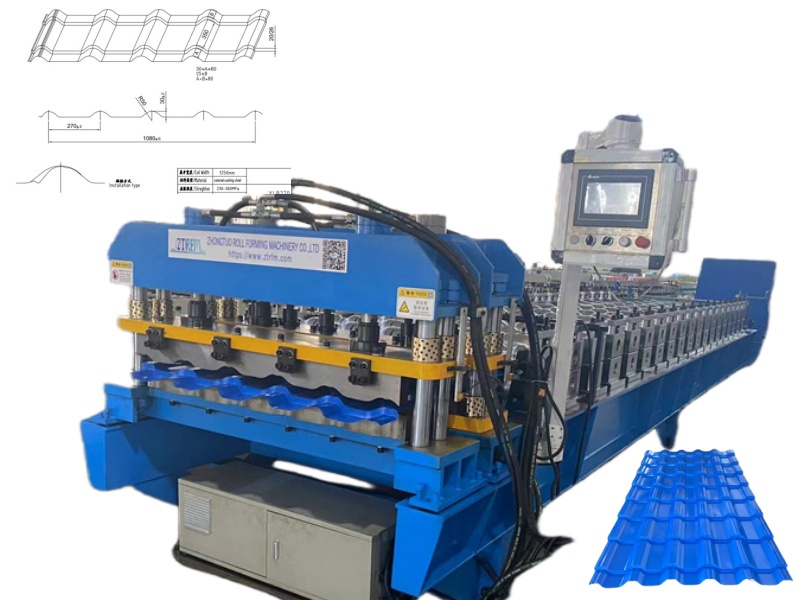

Double-Layer Ridge Capping Roll Forming Machine In modern roofing construction, ridge caps play a critical

Mangalore Tile Profile Sheet Roll Forming Machine Overview of Mangalore Tile Profile Sheet Roll Forming

Metal Ridge Capping Making Roll Forming Machine Efficient, Accurate & Worry-Free Roofing Profile Machine The

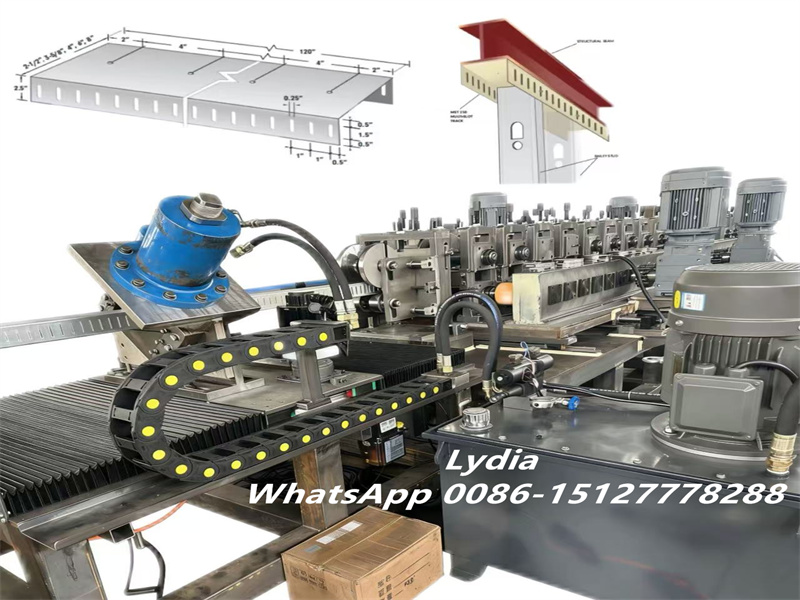

C Channel Light Steel Keel Stud and Track Roll Forming Machine High-Precision Drywall CU/CW Profile

STAY IN THE LOOP