Aluminium Coil Cut to Length Line Machine

High-Precision Sheet Leveling and Cutting Machine

The Cut to Length Line Machine is designed for processing aluminium alloy, stainless steel, carbon steel, galvanized sheet, copper sheet, and other metal coils into flat sheets of the required length. It integrates uncoiling, feeding, leveling, length measurement, cutting, and stacking into one automated working line, ensuring fast and accurate sheet preparation for downstream fabrication.

Cut to Length Line Machine

This system is ideal for industries such as metal packaging, construction materials, electrical panel fabrication, appliance manufacturing, automotive parts, and sheet metal workshops.

Key Features of the cut-to-length line machine

- Suitable Material Thickness: 0.3mm – 2.0mm (custom up to 3.0mm available)

- Max Working Speed: 30m/min (adjustable by frequency inverter)

- High Precision Servo Length Control for accuracy and repeatability

- Stable Hydraulic Cutting System ensures smooth edges

- CNC Touch Screen Operation for simple parameter setup and monitoring

- Supports GI / PPGI / Aluminum / Stainless Steel / Copper Coils

cut to length machine

Technical Parameter Overview of Aluminium Coil Cut to Length Line Machine

| Item | Specification |

|---|---|

| Coil Outer Diameter | Max. 1600mm |

| Coil Inner Diameter | 508mm |

| Thickness Range | 0.3mm – 2.0mm (optional up to 3.0mm) |

| Line Speed | Up to 30m/min |

| Decoiler Motor Power | 7.5 kW |

| Coil Loading Capacity | 5 tons |

| Leveling Stations | 3–6 stations (based on material) |

| Control System | PLC + Servo Feed + Touch Screen |

| Length Accuracy | ±2mm |

Work Flow

Decoiler → Feeding → Leveling → Length Measuring → Cutting → Stacking

The feeding roller ensures stable strip positioning, while the leveling unit removes coil stress for flat, smooth sheet surfaces. A servo-controlled measuring system ensures precise cutting. Sheets are then stacked neatly and ready for packaging or direct processing.

Cut to Length Line Machine

Core Components

1. Hydraulic Decoiler

- Automatic expansion shaft

- Supports up to 5 tons of coil weight

- Equipped with an anti-loosening pressure arm

2. Leveling System

- High-strength rubber shafts

- Ensures sheet flatness and eliminates internal stress

3. Servo Feeding + Precision Length Control

- Ensures ±2mm cutting precision

- Speed is adjustable without stopping the machine

4. Hydraulic Cutting Unit

- Fast, clean cross-cutting

- Stable performance under continuous production

5. PLC + HMI Touch Control

- Multi-language interface (English / Chinese)

- Easy operation & parameter storage

6. Stacking System

- Manual table or automatic stacker, optional

Applicable Materials

- Aluminium Alloy Sheets

- Galvanized Steel Coil (GI/GL)

- Color Coated Steel (PPGI/PPGL)

- Stainless Steel Sheet

- Copper / Brass Sheets

- Carbon Steel Sheet

Advantages of Our Cut-to-Length Line

| Benefit | Description |

|---|---|

| High Cutting Accuracy | Servo control guarantees precise sheet length |

| Smooth Sheet Surface | Leveling removes stress and waviness |

| Easy Operation | PLC touch screen simplifies setup |

| Strong Structure | Thick steel frame ensures long-term stability |

| Customizable | Line configuration can be adjusted to material type and capacity requirements |

Request a Quote

Tell us your requirements:

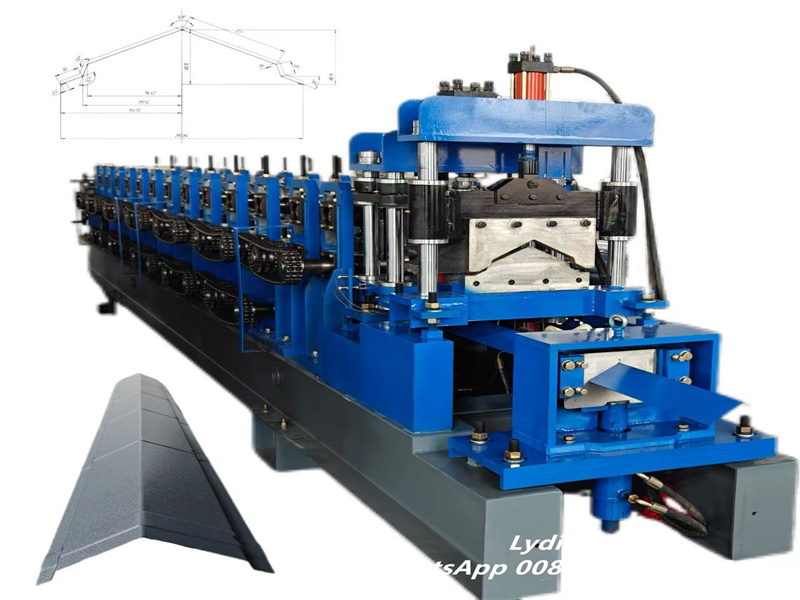

Double-Layer Ridge Capping Roll Forming Machine In modern roofing construction, ridge caps play a critical

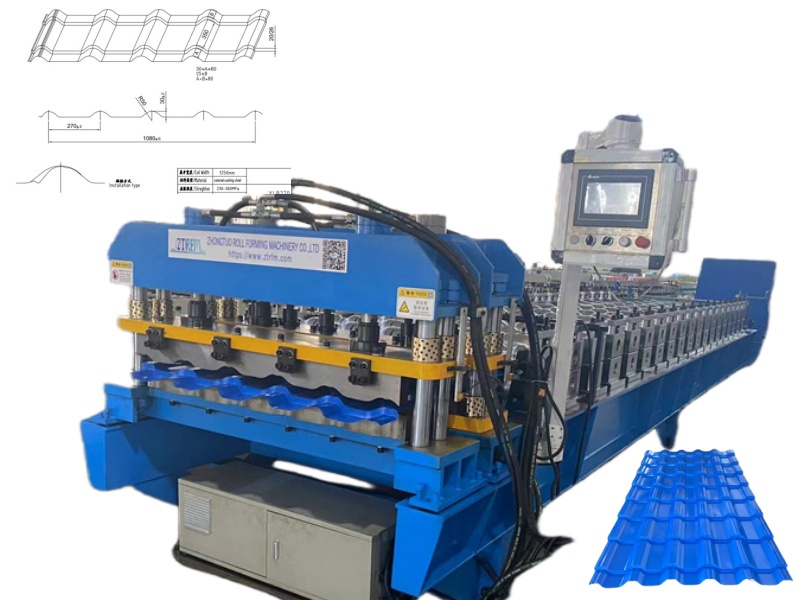

Mangalore Tile Profile Sheet Roll Forming Machine Overview of Mangalore Tile Profile Sheet Roll Forming

Metal Ridge Capping Making Roll Forming Machine Efficient, Accurate & Worry-Free Roofing Profile Machine The

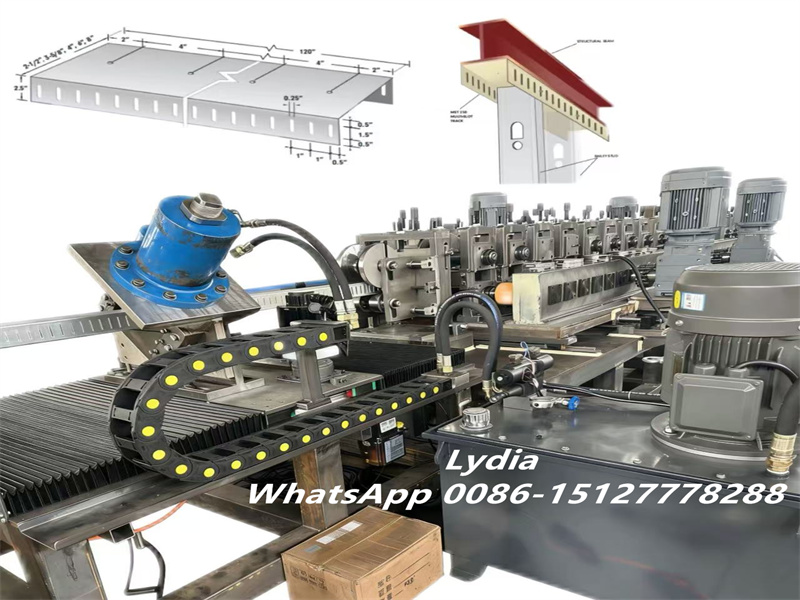

C Channel Light Steel Keel Stud and Track Roll Forming Machine High-Precision Drywall CU/CW Profile

STAY IN THE LOOP