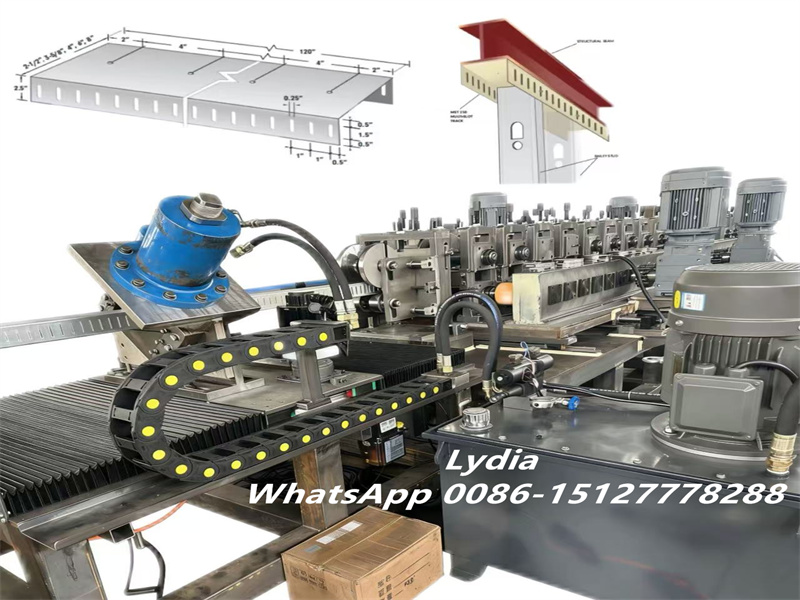

Cable Tray Machine Profile Drawing:

Cable Tray Roll Forming Machine

CABLE TRAY MACHINE INFO. OF STEEL MATERIAL:

Ø Raw material request: Galvanized steel

Ø Material thickness: 0.6-1.2mm

n Width of finished products: 100/200/300/400/500/600mm

n Height of finished cable tray:50mm

Ø Line working speed: 0-8m/min

Ø Forming speed: 0-10m/min

Ø Power supply: 380V 50Hz 3Ph or according to your standard

Ø Line dimension: 38,0mх2,5mх3,85m

Ø Line weight: 55 Tons

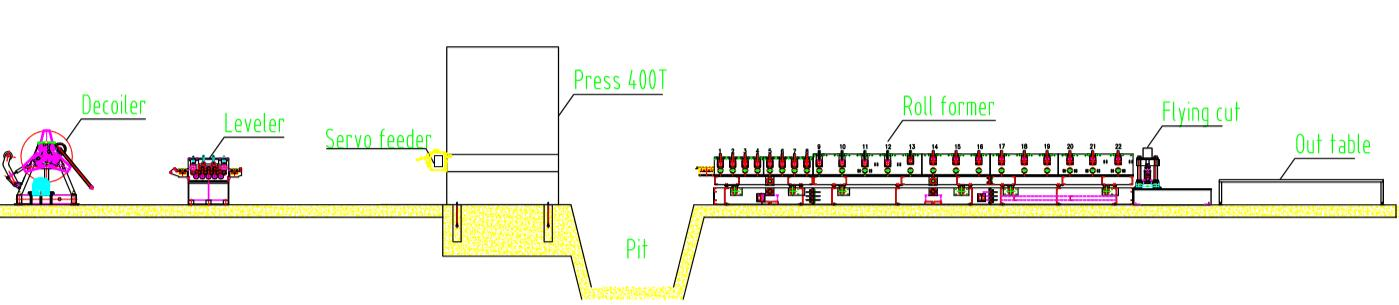

Cable Tray Machine-Flow chart:

Hydraulic Dercoiler–Leveler–Servo feeder–Hydraulic punch–Servo Feeder– 400T Press–Pit– Roll Former–Flying cut&Neck die–Out Table

Cable Tray Machine Flying Hydraulic Cut&Neck Die

Cable Tray Roll Forming Machine

Ø Work from: 1. Hydraulic cut 2. Non-stop cut 3. Neck die&Cut same time

Ø Power of servo motor: 5.5kw, Yaskawa

Ø Cutting speed: same as forming speed

Ø Raw material of cutting blades: SKD11, HRC>62°

Ø No. Of cutting blades: 8 blades

Ø Way of changing blades: Manually change cut blade

Ø Change time: around 10 minutes

Ø Tolerance of length:≤+/- 0.5mm

Ø Length encoder brand: Koyo

Ø Hydraulic station power: 15kw, offered by hydraulic station

Cable Tray Roll Forming Machine

PLC Control Cabinet

Cable Tray Roll Forming Machine

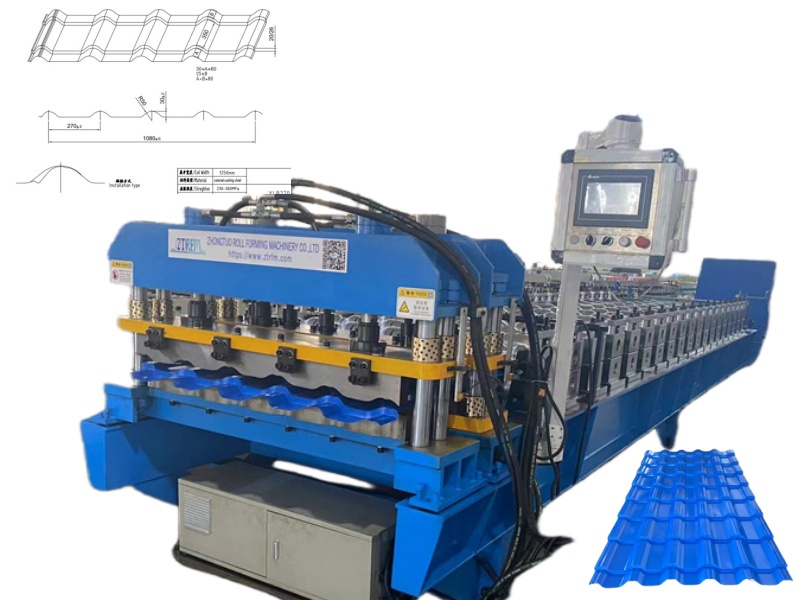

Double-Layer Ridge Capping Roll Forming Machine In modern roofing construction, ridge caps play a critical

Mangalore Tile Profile Sheet Roll Forming Machine Overview of Mangalore Tile Profile Sheet Roll Forming

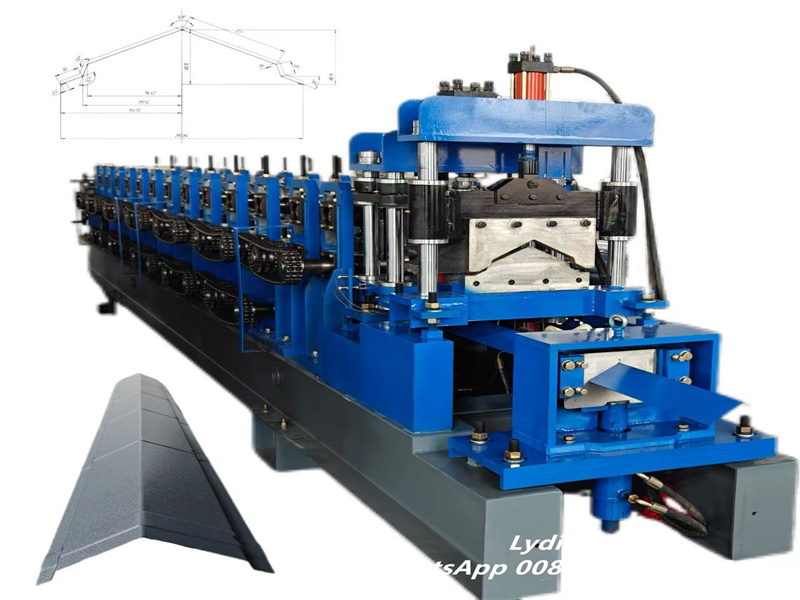

Metal Ridge Capping Making Roll Forming Machine Efficient, Accurate & Worry-Free Roofing Profile Machine The

C Channel Light Steel Keel Stud and Track Roll Forming Machine High-Precision Drywall CU/CW Profile

STAY IN THE LOOP