The Composite Steel Deck Machine produces permanent metal formwork for cast-in-place concrete slabs. With engineered embossments that mechanically bond with the concrete, composite decks boost slab shear and bending strength while eliminating traditional wood forming—slashing material waste, labor, and cycle times.

Benefits of Composite Metal Floor Decking

Superior Composite Action: Embossments (1.5″, 2″, 3″ depths) grip concrete as it cures, dramatically increasing floor system stiffness and load capacity.

Zero Net Weight Increase: Embossing doesn’t add dead weight to the decking panel, avoiding costly structural upsizing.

Permanent Form work: Eliminates wood form installation and teardown—reducing construction schedule by up to 30%.

Flexible Depth Options: Select from 1.5″, 2″, or 3″ embossment depths to meet specific span and load requirements.

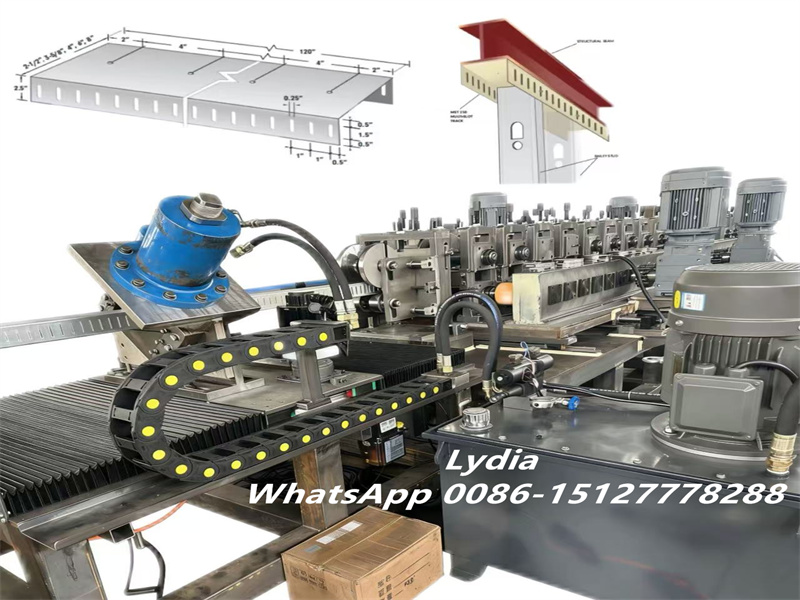

1.5″ composite floor deck panels Machine

Primarily used as a form for concrete slabs, 1.5″ composite floor deck panels Machine feature raised embossments that interlock with the cured concrete, creating a solid mechanical bond. When combined with reinforcing elements such as rebar or welded wire mesh, they significantly enhance slab strength. Acting as permanent formwork, these steel decks both support the structure and eliminate the time and expense required for traditional wood forming.

1.5” Composite Deck Roll Forming Machine

2” composite floor deck panels Machine

2” composite floor deck panels Machine serve primarily as permanent formwork for concrete slabs. Featuring embossed ribs that mechanically interlock with the poured concrete, these steel decks are typically reinforced with rebar or welded wire mesh to create a robust bond. By combining structural support and positive reinforcement, composite steel decking removes the need for traditional wood forms—saving both time and labour.

3” composite floor deck panels Machine

3” composite floor deck panels Machine serve as permanent forms for cast-in-place concrete slabs. Their embossed ridges lock into the curing concrete—often reinforced with rebar or welded wire mesh—to create a unified, high-strength bond. Because the steel deck remains in place, it provides continuous reinforcement and removes the labor and material costs associated with traditional wood formwork.

2.0″ Dovetail Metal Deck Machine

The dovetail roof and floor deck merges the load-bearing strength of structural decking with the clean, linear plank aesthetic. Its distinctive profile permits longer spans at reduced slab depths, allowing more levels within the same building height. In addition, dovetail decking excels in acoustics: its flute geometry accommodates more sound-absorbing insulation than standard profiles, which is why it’s widely specified for gymnasiums, auditoriums, and theaters.

3.5″ Dovetail Metal Deck

As a 3.5″-deep structural solution, this deck provides a clean, finished appearance in exposed ceilings while permitting extended spans with minimal overall depth. The dovetail roof and floor deck combines the robustness of structural metal with the sleek, linear look of plank-style panels Machine. Its distinctive geometry allows you to cover greater distances at reduced deck thickness—ideal for maximizing usable floor-to-floor height in multi-story buildings. Moreover, the flute-shaped channels accommodate more sound-absorbing materials than standard profiles, delivering superior acoustic performance for applications like gymnasiums, auditoriums, and theaters.

Technical Parameters for Roll Forming Line

Product Sheet

| Series | Details / Parameter |

| Raw Material | Galvanized steel |

| Material Thickness | 18–20 gauge |

| Feeding Width | As requested |

| Cutting Length | Adjustable |

Part 1: Decoiler

Supports and uncoiling of coils (capacity up to 22,000 lbs)

Hydraulic expansion mandrel for inner diameters φ510–φ610 mm, with cantilever

Motor-driven forward/reverse uncoiling with tension control; brake system included

Max coil width: 1250 mm; feeding speed: 0–20 m/min; drive motor: 5.5 kW; hydraulic motor: 4 kW

Structure: welded steel plates and profiles

Hydraulic Entry Coil Car

Horizontal and vertical movement for coil loading; capacity 22,000 lbs

Vertical lift by hydraulic cylinder with 4 guide pillars

Horizontal travel driven by 3 kW motor at 6–7 m/min

Automatic return and retrieval of leftover coils after loading

Part 2: Main Roll Forming Machine

Feeding Device

Adjustable-width platform with bearings to protect sheet edges.

Shafts & Rollers

Shafts: 45# steel, hard chrome plated (Ø 90 mm), tempered for hardness.

Rollers: GCr15 and 45# steel, 0.05 mm chrome coating for wear resistance.

Stations: 28 (including embossing station); Speed: 0–15 m/min.

Structure: 20 mm middle plate; Frame: 400# H-beam with diagonal bracing.

Bearings: Harbin; Drive: 2×15 kW motors; Transmission: 1.5″ double chain.

Part 3: PLC Control System

| Component | Specification |

| Frequency Inverter | Delta |

| PLC | Delta |

| HMI | Touch screen & buttons (EN/CN/ES) |

| Electrical Parts | Schneider |

| Counter | Omron |

| Functions | Length, quantity, and speed control |

Control station uses aviation plugs for plug-and-play setup.

Part 4: Cutting System

| Parameter | Details |

| Type | Hydraulic shearing |

| Motor Power | 5.5 kW |

| Blade Material | GCr12, quenched to HRC 58–62 |

| Length Tolerance | ±2 mm |

| Valve | 1 set solenoid valves |

| Frame | Pillar-type |

| Connections | Numbered tubes & wires |

| Pump | Hydraulic with cooling |

Part 5: Automatic Product Table

Auto-stacker unloads cut profiles onto existing stacks without damage

Mechanical unload compatible with forklift (customer-supplied)

Air-assisted pick-up (5.5 kW compressor by customer)

Air cylinder swing arm: 40×80 mm

Transmission: 3 kW motor, 1.0″ double chain

Rollers: ASTM1045, chrome plated, Ø 80 mm

Capacity: up to 5,000 kg; length 500–6,000 mm; max height 300 mm

Metal Ridge Capping Making Roll Forming Machine Efficient, Accurate & Worry-Free Roofing Profile Machine The

C Channel Light Steel Keel Stud and Track Roll Forming Machine High-Precision Drywall CU/CW Profile

Top Hat Roll Forming Machine The Top Hat Roll Forming Machine is a high-performance production

Container house frame making machine Australian specification standards shipping living container house frame making machine is

STAY IN THE LOOP