Galvateja Roofing Roll Forming Machine

To create a one-stop service provider, we will provide the following related products

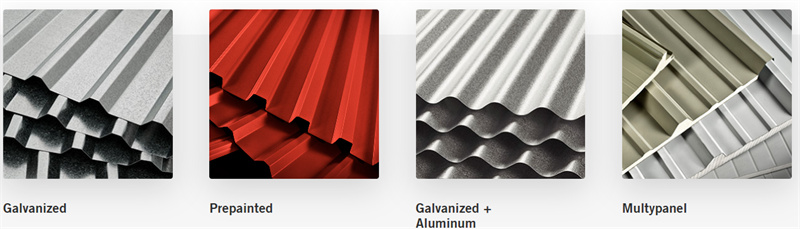

Galvanized,Zinc-coated sheet for extended useful life of the product

Prepainted,Corrosion- resistant prepainted galvanized or electrogalvanized sheet

Galvanized + Aluminum,Sheet coated on both sides with an aluminum-zinc alloy

Multypanel,Prefabricated construction system for optimum insulation

Technical Description of Mexican Galvateja Metal Roofing Tile Roll Forming System

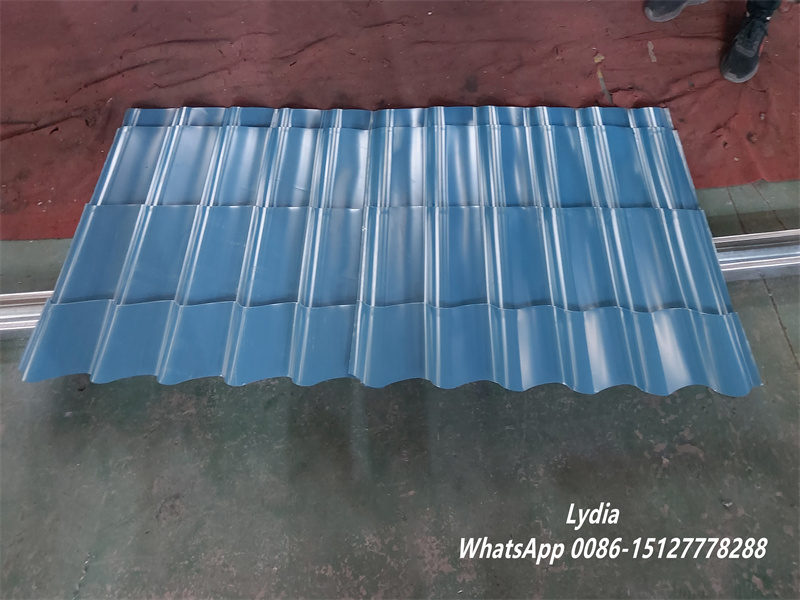

The Mexican Galvateja Metal Roofing Tile Sheets Color-Coated Roll Forming Machine is specialized equipment designed to produce high-quality steel glazed roofing panels. These tiles are fabricated by feeding horizontally aligned color-coated steel coils through a precision roll-forming system. While diverse variants of color-coated sheets exist, they primarily fall into two categories: roofing sheets for exterior applications and wall panels for structural cladding. The glazed metal tiles, commonly employed as roofing materials, enhance both the aesthetic appeal and durability of steel-framed buildings, ensuring long-term structural integrity.

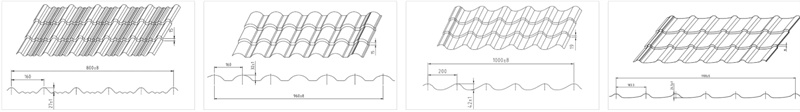

here suggest some popular tile, such as aluminiun metecoppo tile and steptile in Nigeria ,galvateja in Mexico, clasic steptile is most popular in world, monterry tile is popular in Russia

Advantages of Steel-Framed Construction

Steel-based architectures prioritize resource efficiency. Load-bearing walls utilize profiled steel components (e.g., C/Z-beams), complemented by composite panel cladding and Galvateja glazed tile roofing. This approach minimizes material waste while maintaining structural robustness.

Design and Functionality of Galvateja Metal Roofing Tile Roll Forming Machine

The production machinery for color-coated glazed tiles integrates cast iron and steel components. Its foundation comprises H-beams supporting dual frame structures, arranged in multiple rows with designated spacing to accommodate shape-pressing shafts. Each shaft is custom-engineered to match specific tile profiles, interconnected via chain drives and powered by a reducer system. Automated operation is achieved through a PLC-controlled reducer, enabling precise adjustment of tile length and waveform geometry.

The machine above is Pattern Cut , and the next machine is a Flat Cut.

Production Workflow for Galvateja Metal Roofing Tile Roll Forming Machine

Hydraulic Decoiler: Unwinds steel coils (5-7.5T capacity).

Guiding System: Aligns materials for feed consistency.

Roll Forming Unit: 16-stage forming with φ75mm chromed alloy rollers.

Hydraulic Cutting: Stamping at 300mm intervals + programmable length trimming.

Output Conveyor: Manual 2m×2m receiving platform.

Galvateja Tile Variants

3D Contoured Tiles: Feature wave-synchronized trimming via mold-based cutting (premium-grade).

Standard Shear-Cut Tiles: Economical vertical shearing method.

Both styles remain highly sought-after in the Mexican construction market.

Technical Specifications of Glazed Tile Machine

| Suitable material | PPGI coils & Aluminium coils ;0.5-0.6mm |

| Working speed | About5- 6m/min |

| Step distance | Adjustable according to requirement (>=250mm) |

| Power Requirement | Main motor power: 5.5 Kw

(Depend on final design) |

| Hydraulic station power: 5.5Kw

(Depend on final design) |

|

| Material of rollers | No.45 steel, plated with chrome on surface. |

| Material of cutter,

pressing die |

Cr12 mould steel with quench treatment, HRC58-600 |

| Material of shaft | High quality 45# steel, Dia. is 72mm.

Roller grinder milling. |

| Shaft diameter | 72mm |

| Controlling system | Mitsubishi PLC & converter |

| Total weight of machine | About 9500KGS |

| Machine’s size | About 18m×1.8m× 1.5m (Depend on final design) |

This system exemplifies modern manufacturing integration, combining mechanical precision with automated control to deliver customizable, cost-effective roofing solutions.

Engineered by Zhongtuo for Precision and Surface Protection As patio and pergola structures become more

Zhongtuo Industrial Cable Tray Roll Forming Production Line Zhongtuo Cable Tray Roll Forming Machine is

Full Automatic Steel Supermarket Shelves Storage Rack Upright Pillar Roll Forming Machine Improve Warehouse Efficiency

Cable Ladder & Cable Tray Roll Forming Machine High-Efficiency Steel Side Rail Forming Machine for

STAY IN THE LOOP