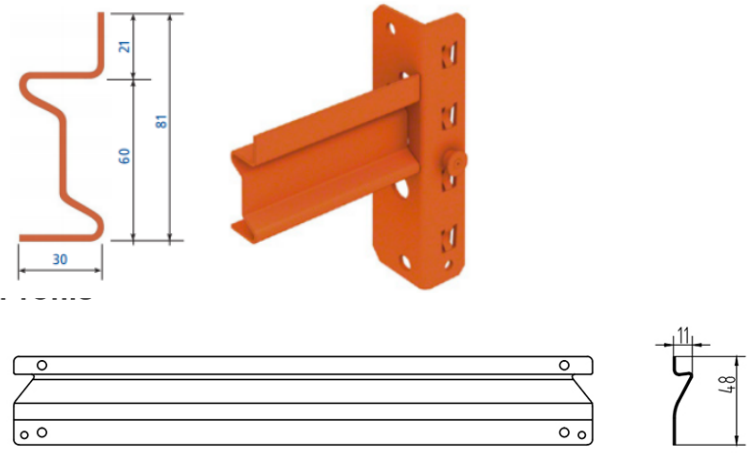

The Z-beam racking system is designed to create a unique, low-profile racking system that maximizes vertical storage efficiency. The system features a Z-beam structure that minimizes rack height while increasing inter-level clearances for more spacious storage.

This racking method stands out for its practicality and high usability with a compact bolt-on construction. The unique Z-beam geometry allows the particleboard platform or shelf to be perfectly flush on top of the beam, eliminating raised edges and creating a clean, streamlined look. The result is a system that combines high load-bearing capacity with aesthetics, making it an ideal choice for cost-effective, light-duty storage applications.

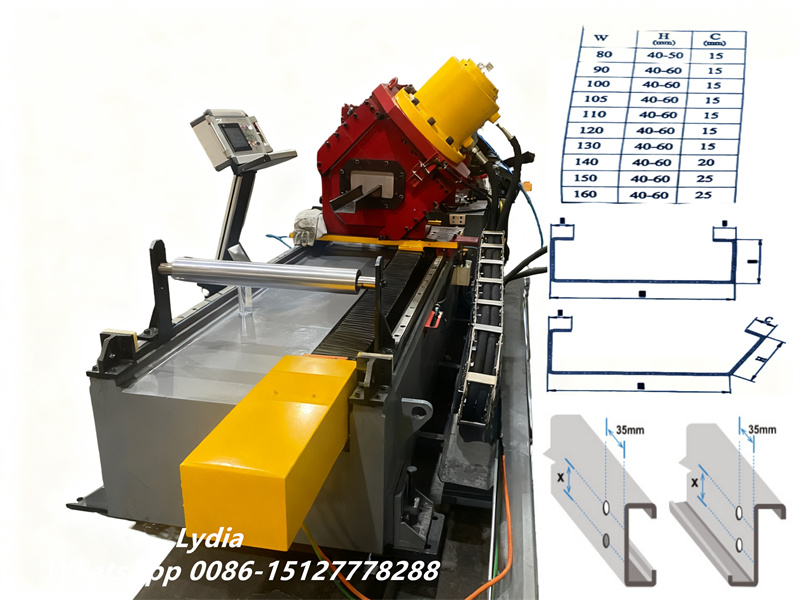

The Z Beam Roll Forming Machine, also referred to as a picking beam roll former, is fully automated and capable of mass-producing Z-type support beams. These beams are often used in racking systems where shelving levels are required for picking and storing loose items. Each Z beam is formed with an integrated four-hook connector at both ends, folded to create a retaining edge that holds the shelving securely in place.

Commonly used in pallet racking systems, Z beams manufactured by this machine help create multiple picking levels efficiently. The Z Beam Boltless Shelving Roll Forming Machine enables reliable and fast production of these profiles, and compatibility with various racking setups.

Z Beam Roll Forming Machine Technical Specification

| Item | Specification |

| Suitable Material | HCR Coil / Carbon Steel Coil, GI Coil |

| Material Thickness | 0.8–2.5 mm |

| Profile | 90/100/120*70 mm |

| Line Speed | 20 m/min |

Production Flow

Steel Coil → Straightening Machine → Punching Machine → Roll Forming Machine → Hydraulic Cut Off → Run Out Table → Finished Product → PLC Control

Decoiler

| Category | Item | Specification |

| Decoiler | Coil Outer Diameter | Max. 1600 mm |

| Coil Inner Diameter | 460 – 520 mm | |

| Coil Width | 500 mm | |

| Coil Weight | Max. 3000 kg | |

| Tensioning Method | Manual with Manual Brake | |

| Special Feature | With Anti-Uncoil Frame | |

| Leveling Machine | Material Width | 400 mm |

| Material Thickness | Up to 2.5 mm | |

| Rollers | 11 pcs (GCr15 steel, HRC55–57°) | |

| Transmission | Chain and Gear | |

| Motor Power | 3 kW | |

| Material Feeder | Feeding Width | 400 mm |

| Feeding Thickness | 2.5 mm | |

| Rollers | 4 pcs (GCr15, HRC55–57°) | |

| Servo Motor | 1.8 kW | |

| Transmission | Gear-driven | |

| Power Press | Punching Pressure | 80 Tons (Air Clutch) |

| Punching Frequency | Up to 60 times/min | |

| Punching Moulds | 3 sets (90 mm, 100 mm, 120 mm) | |

| Main Roll Forming | Material Thickness | 1.8 – 2.5 mm |

| Adjust Width | By spacer | |

| Roller Stations | 24 groups | |

| Straightening Rollers | 5 pcs | |

| Roller Material | GCr15, HRC55–57°, polished | |

| Main Shaft Diameter | 60 mm (45# steel) | |

| Bearings | 60310 series | |

| Wall Plate Thickness | 30 mm | |

| Drive Mode | Gear and Chain | |

| Drive Motors | 3 sets of 5 kW | |

| Cooling System | Water Cooling Equipped | |

| Hydraulic Cut-Off | Hydraulic Station | 1 set |

| Motor Power | 4 kW | |

| Cutting Moulds | 4 sets | |

| Blade Material | SKD11 (HRC60–62°) | |

| Cutting Mode | Stop-to-Cut | |

| Run-Out Table | Length | 6 meters |

| Structure | Welded Angle Steel | |

| Discharge Type | Pneumatic | |

| Control System | Controller | PLC with Touchscreen |

| Length Control | Encoder-based | |

| Speed Control | Transducer (Inverter) | |

| Electrical Components | High-quality branded parts | |

| Power Supply | Customized as required |

Z-beam Roll Forming Machine

Z-beam Roll Forming Machine

Z-beam Roll Forming Machine

Stainless Steel & Aluminum Door Frame Making Machine The stainless steel and aluminum door frame

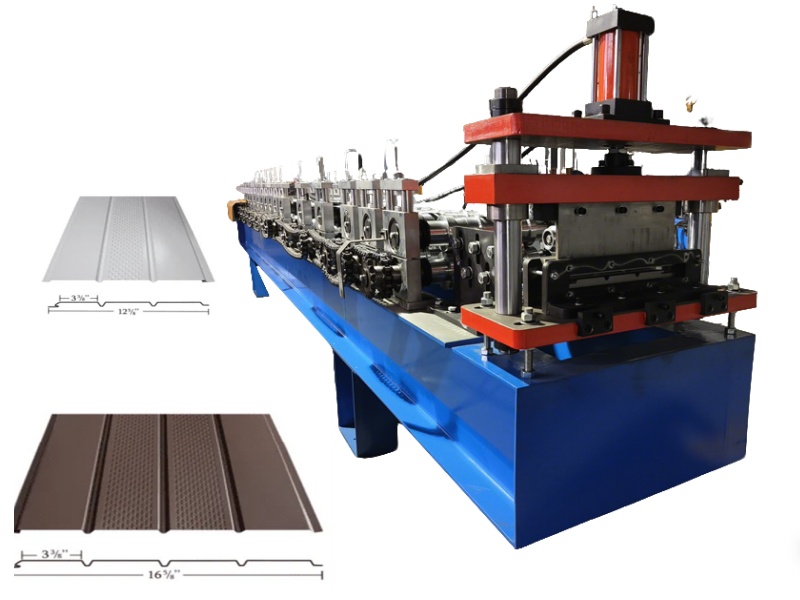

The ZTRFM Soffit Panel Roll Forming Machine is engineered for manufacturers who require fast, stable,

Cee & Zee Eave Struts Roll Forming Machine for Metal Buildings High-Performance Purlin Mill In

We are pleased to announce the successful delivery of our high-performance double-layer trapezoidal RIB metal

STAY IN THE LOOP