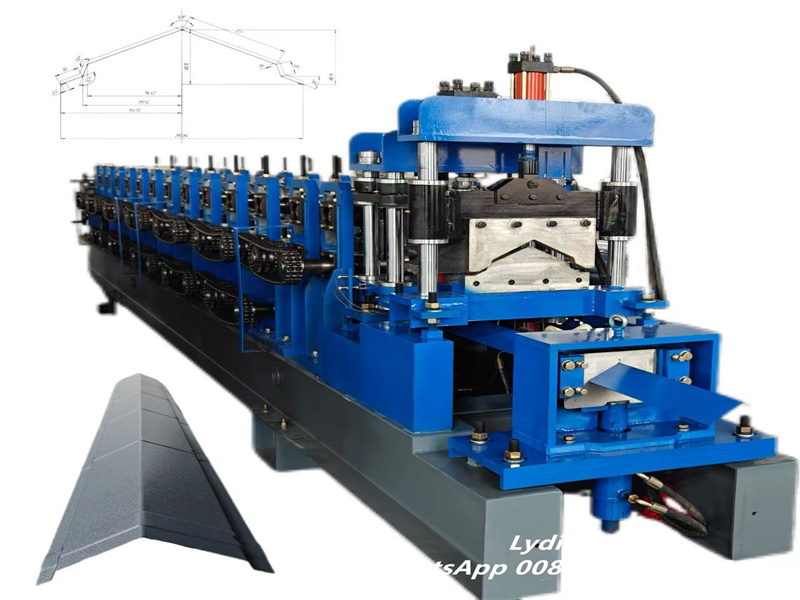

Fully automatic CZ combination Purlin Machine (Model CZ):

A high-tech, programmable machine that produces both C and Z purlins with quick, automatic adjustments—ideal for flexible, precise output.

Leveling feed

The leveling mechanism in the machine is mainly composed of a feeding roller (guiding and feeding roll), a guiding roller (tracting and driving the material roll to feed at a certain speed), and leveling roller. Among them, the function of leveling the coil material is the leveling roller in the right picture. In this example, it is an upper ,3 lower 4 structure. For rolls of different materials, different thicknesses, and different hardness, other equipment is also equipped with an upper 2 lower 3 structure or no leveling structure (for example, the G550 material used by LG has a relatively hard hardness, and the roll can still maintain a good flatness, so no leveling mechanism was added to the design).

Pre-punching and pre-shearing

The function of the pre-shearing is to trim the end of the material roll to ensure that the end of the material roll is even, and the pre-shearing can also be cut to length according to production requirements. The advantage of pre-shearing is that there is no waste materi,al and the shearing speed is fast. The disadvantage is that it cannot produce short materials, and the shape of the plate is easy to open. (Slab shape opening: the opening means that the verticality of the profile section is greater than 90°, which is beyond the required range of the plate shape.)

Technical Specification:s Completely automatic CZ combination Purlin Machine

| Category | Specification |

| Power Transmission | 2 × 15 kW , 1 × 7.5 kW |

| Motor + Pump | 11 kW – 45 cc |

| Automatic Size Change | 3 × 1.5 kW |

| Punch Table | 2 × 1.5 kW |

| Machine Weight | 28 ton |

| Dimensions (L×W×H) | 16 m × 2.5 m × 2.0 m |

| Forming Speed | 16–20 m/min (no punching), slower with punching |

| Roller Stations | Lip forming: 6, Side forming: 11, Pulling: 5, Anti-flare: 1 |

| Transmission | Electric motor + gearbox |

| Cutting System | Hydraulic cylinder, part & scrap cutting |

| Punching System | 3 servo-positioned hydraulic stations |

| Control | PLC + HMI programmable |

| Size Range | C100–C350 mm, Z100–Z350 mm |

| Material Thickness | 1.2–3.2 mm |

| Material Width | C: 200–563 mm, Z: 206–569 mm |

| Yield Strength | G300–G550 MPa |

Key Advantages of CZ Purlin Machine

Full automation: Instant switching between C and Z shapes, with dimensions adjusted diagrammatically.

Flexibility: Processes galvanized or black steel within 1.2–3.2 mm thickness range, covering a wide spectrum of sizes.

Precision & speed: Advanced servo controls ensure rapid, repeatable shape changes and high forming speeds.

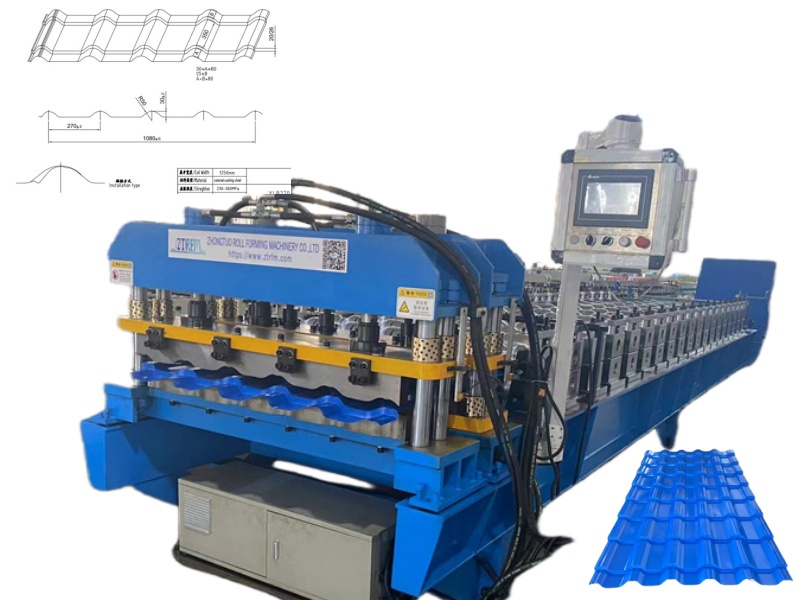

Double-Layer Ridge Capping Roll Forming Machine In modern roofing construction, ridge caps play a critical

Mangalore Tile Profile Sheet Roll Forming Machine Overview of Mangalore Tile Profile Sheet Roll Forming

Metal Ridge Capping Making Roll Forming Machine Efficient, Accurate & Worry-Free Roofing Profile Machine The

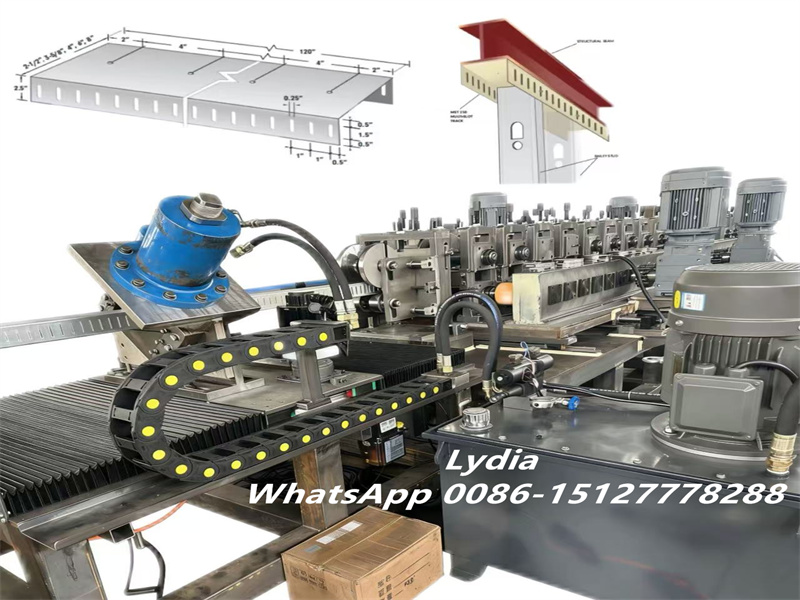

C Channel Light Steel Keel Stud and Track Roll Forming Machine High-Precision Drywall CU/CW Profile

STAY IN THE LOOP