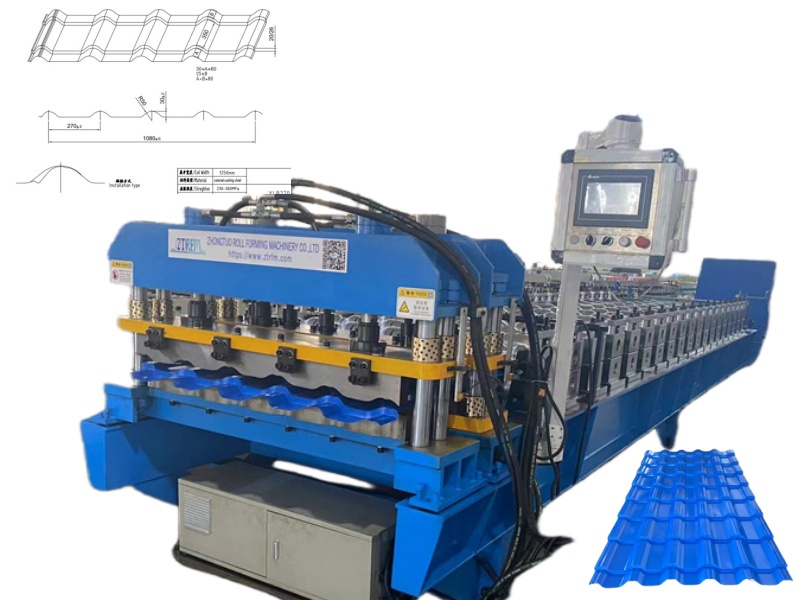

In India’s fast-growing construction industry, the demand for durable and visually appealing roofing materials continues to rise. To meet this need, the Automatic Double Layer Glazed Tile Roll Forming Machine offers an advanced and cost-effective solution for manufacturing both corrugated roof panels and glazed roofing tiles on a single production line.

This high-performance roof sheet forming machine is widely used by roofing product manufacturers who seek automation, efficiency, and consistent quality output.

Roof Tile Roll Forming Machine

The automatic double-layer roof sheet roll forming machine integrates two different forming systems into one frame.

By simply switching control modes, users can produce glazed tiles or corrugated sheets without changing molds or tools.

Equipped with PLC automatic control and hydraulic cutting technology, the system ensures smooth operation, precise length measurement, and minimal material waste — all essential for high-volume production lines in India’s roofing sheet manufacturing sector.

Roof Tile Roll Forming Machine

Roof Tile Roll Forming Machine

Technical Highlights: Automatic glazed tile roll forming machine

| Specification | Details |

|---|---|

| Applicable Materials | GI, GL, PPGI, PPGL, Aluminum |

| Thickness Range | 0.3 – 0.8 mm |

| Effective Widths | 762 mm and 686 mm (customizable) |

| Production Speed | 10 – 15 m/min |

| Main Motor Power | 5.5 KW |

| Hydraulic Power | 4 KW |

| Machine Frame | 350H Steel Structure |

| Roller Material | 45# Steel with Hard Chrome Plating |

| Cutting System | Hydraulic cutting with Cr12Mov blades |

| Control System | PLC automatic control with a multilingual interface |

| Voltage | 380V / 50Hz / 3 Phase (customizable) |

Key Features of the double-layer roof sheet roll forming machine

- Automatic PLC Control System

The entire production process — from feeding to cutting — is managed automatically. The PLC system ensures precise cutting length, stable speed adjustment, and easy parameter setting, suitable for multi-language operation environments.

automatic glazed tile roll forming machine

- Dual-Layer Structure for Versatile Output

One frame, two profiles. The machine produces both glazed step tiles and corrugated roof sheets, saving space and investment cost. - Durable Rollers and Frame Design

Rollers are made from 45# high-carbon steel, heat-treated and chrome-plated for long service life. The 350H steel base frame enhances overall machine rigidity and reliability. - Efficient Hydraulic Cutting

The Cr12Mov cutting blades and double guide post design ensure clean, accurate, and burr-free cuts for every roof sheet.

Main Components of the corrugated roof panel forming machine

Feeding Section – Guides the coil smoothly into the rollers while reducing waste through precise manual shearing.

Roof Tile Roll Forming Machine

Roll Forming System – Accurately forms the desired profiles using precision-machined rollers.

Hydraulic Cutting Unit – Performs fast and clean cutting with consistent accuracy.

Roof Tile Roll Forming Machine

Electric Control Cabinet – Houses the PLC system and frequency converter, ensuring stable automatic operation and real-time production data monitoring.

- Roofing sheet factories and steel construction material suppliers

- Building material distributors in Delhi, Mumbai, Chennai, and Pune

- Industrial and residential roofing panel production lines

- Prefabricated building and warehouse projects

Advantages for Indian Roofing Manufacturers

- Increased Productivity: Continuous automatic production minimizes downtime and maximizes sheet output.

- High Adaptability Compatible with popular Indian roofing sheet standards and raw materials such as PPGI and PPGL.

- Energy-efficient optimized motor and hydraulic system reduce power consumption.

- Low Maintenance Cost Durable components and reliable control systems lower long-term maintenance needs.

- Strong After-Sales Support: Online technical service, spare parts supply, and installation guidance available worldwide.

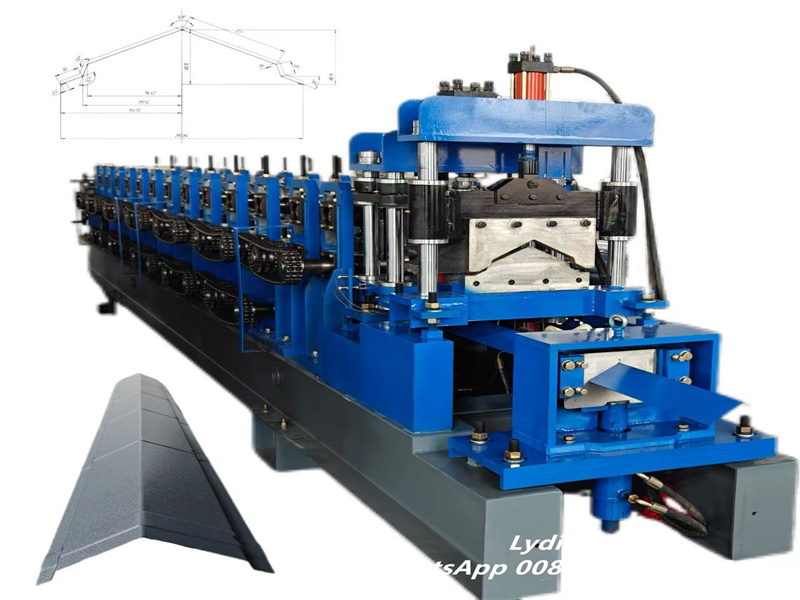

Double-Layer Ridge Capping Roll Forming Machine In modern roofing construction, ridge caps play a critical

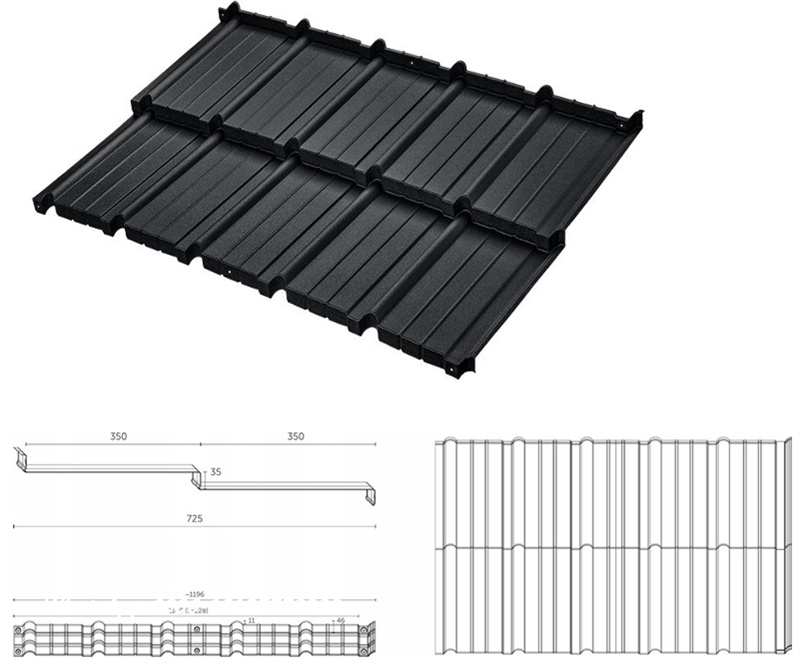

Mangalore Tile Profile Sheet Roll Forming Machine Overview of Mangalore Tile Profile Sheet Roll Forming

Metal Ridge Capping Making Roll Forming Machine Efficient, Accurate & Worry-Free Roofing Profile Machine The

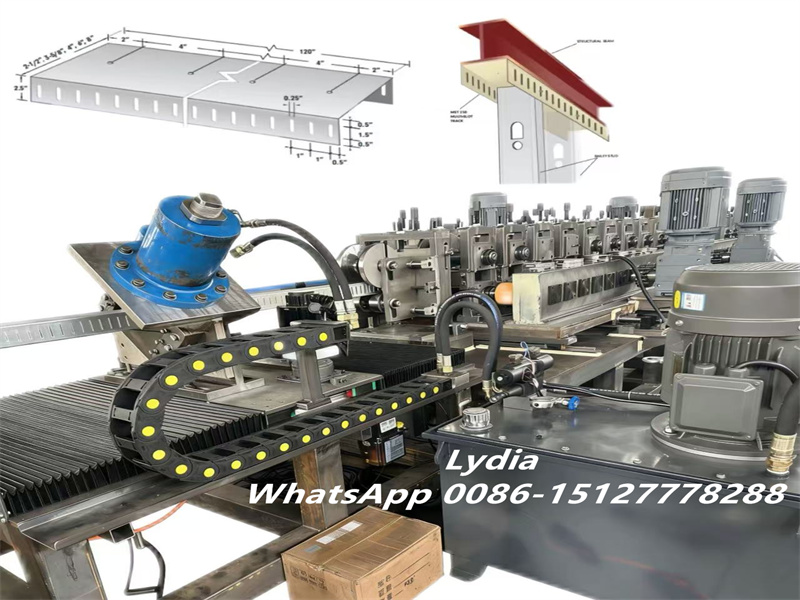

C Channel Light Steel Keel Stud and Track Roll Forming Machine High-Precision Drywall CU/CW Profile

STAY IN THE LOOP