Our suspended ceiling machine line is capable of producing suspended ceiling tiles and panels with various thicknesses, widths, and material types. We also offer custom mold designs to create different perforation patterns and panel styles tailored to specific suspended ceiling tile requirements.

Primarily, we manufacture metal ceiling tile production lines focused on standard suspended ceiling panels such as Lay-In, Clip-In, and Lay-On types. Additionally, we can customize production lines based on clients’ special requests, accommodating panel widths up to 2,000 mm and supporting a wide range of raw materials. Commonly used metals for suspended ceiling panels include stainless steel, aluminum, galvanized steel, cold-rolled steel, hot-rolled steel, copper, brass, thin metals, Inconel, Monel, and titanium.

Our suspended ceiling tile production lines are designed as fully automated systems, offering high precision, increased production capacity, and minimal labor requirements.

Suspended Ceiling Tiles Usage

Suspended metal ceiling panels are widely utilized in locations such as metro stations, airports, shopping centers, train stations, hospitals, government buildings, offices, and similar structures. These metal ceiling tiles are preferred for their excellent sound insulation, durability, hygiene, fire resistance, superior air circulation, and decorative appeal.

Suspended Ceiling Machine

In modern construction and interior decoration, the demand for diverse materials is growing, especially for ceilings and walls. ZTRFM CEILING MACHINERY offers a range of efficient and versatile equipment, including baffle ceiling machines, linear strip ceiling machines, open cell ceiling machines, hook-on ceiling tile machines, and wall panel cladding machines.

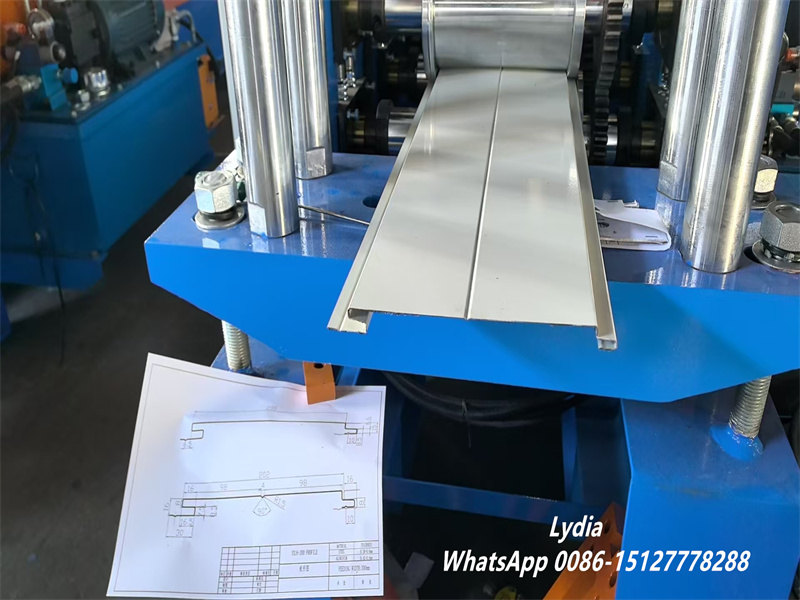

Hook-On Ceiling Tile Machine

This machine produces various hook-on ceilings, both flat and perforated, supporting common sizes like 300×300 mm, 300×600 mm, up to 1000×1000 mm. It includes a decoiler, straightener, main roll forming machine, and cut-to-length system. Operating at 380V, 50Hz, 3-phase with 30 kW power consumption, it is computer-controlled for automatic adjustment, ensuring high efficiency and consistent quality. Hook-on ceilings are popular for their simple installation, elegant look, light shielding, and wind resistance, typically installed with a unified hook structure and supporting keel.

Wall Panel Cladding Machine

Designed to produce different wall panels—flat, small and large V-ribs, and pencil ribs—this machine integrates unwinding, feeding, punching, forming, and cutting in one line. Equipped with a PLC system, it offers fully automated operation for improved accuracy and efficiency. The machine can be customized to meet diverse project requirements, making it ideal for enhancing the beauty and comfort of modern buildings.

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP