Australian Style Roller Shutter Door Roll Forming Machine

High Strength • Smooth Operation • Attractive Profile

The Australian Style Roller Shutter Door Roll Forming Machine is specifically designed for manufacturing premium-quality roller doors used in residential garages, commercial buildings, warehouses, and industrial security applications.

Compared with standard roll-up shutter doors, the Australian-style shutter panel is produced in one continuous form, offering:

- Higher structural strength

- Better appearance

- Quieter, smoother lifting

- Longer service life

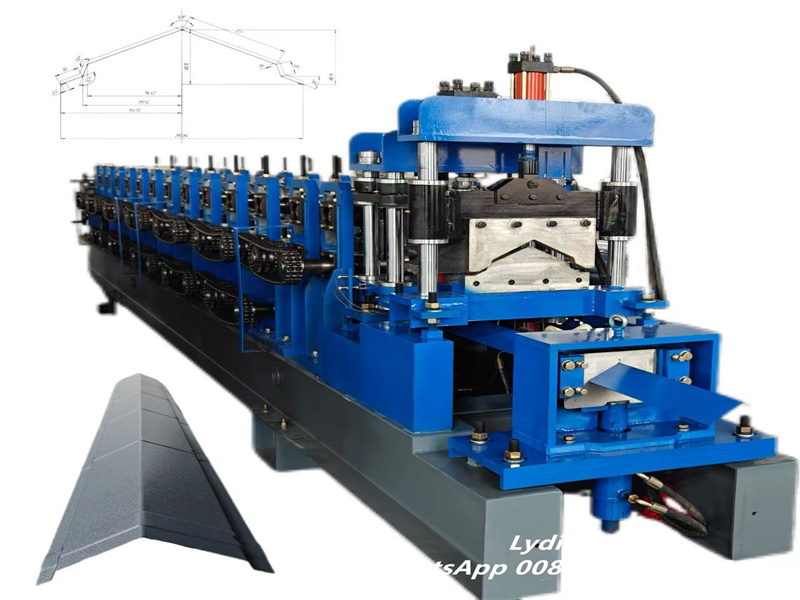

Australia shutter door machine

This makes it a preferred choice in Australia, New Zealand, Southeast Asia, Europe, and Middle East markets where performance and reliability are highly valued.

Key Advantages of roller shutter door roll forming machine

- Separate forming design ensures the door surface is smooth, with no dents or scratches.

- 24 roller stations guarantee precise shaping and a stable lock structure.

- Edge trimming + pre-shearing system makes the lock joint neat and secure.

- Muffler belt system reduces noise and vibration, ensuring quiet door operation.

- An optional spring-balancing system allows the door to remain in any position.

- Waste coil slitting & collecting system allows wider coils to be used without waste.

Australia shutter door machine

Technical Specifications of the shutter door forming machine

| Item | Specification |

|---|---|

| Raw Material | PPGI / GI Coils |

| Material Thickness | 0.6 – 0.8 mm |

| Coil Width | 1250 mm |

| Shaft Material | 45# Steel (Tempered) |

| Shaft Diameter | 70 mm |

| Roller Material | 45# Steel with Hard Chrome Plating |

| Roller Stations | 24 Stations |

| Working Speed | 0–20 m/min |

| Motor Power | 5.5 kW + Hydraulic 5.5 kW |

| Cutting Type | Hydraulic Cutting (Cr12 Steel Blade) |

| Cutting Accuracy | ±1mm / 3m |

| Control System | Delta PLC + HMI Touch Screen |

| Decoiler Capacity | 5 Tons (Manual or Optional Motorized Decoiler) |

Australia shutter door machine

Machine Structure & Components

1. Decoiler (5 Tons)

- Manual expansion

- Brake control system

- Supports coil diameters: 450–550mm

2. Roll Forming Unit

- 24 forming stations

- Carbon steel machine frame with welded H-beam structure

- Chain-driven transmission with protective covers

3. Hydraulic Cutting System

- Two-pillar type cylinder for stable cutting pressure

- Cr12 steel blades heat-treated for long life

4. PLC Control Panel

- Delta frequency & PLC control

- User-friendly HMI touch screen

- Multi-language optional

Applications

- Residential Garage Doors

- Commercial Storefront Security Doors

- Industrial Factory Entrance Doors

- Warehouse Roller Shutter Systems

- Shopfront & Storage Unit Doors

Why Choose ZTRFM

- 10+ years manufacturing experience in forming machines

- Competitive price with factory-direct support

- 1-year warranty + lifetime online technical service

- Custom profile & machine layout available

- Fast delivery and global installation support

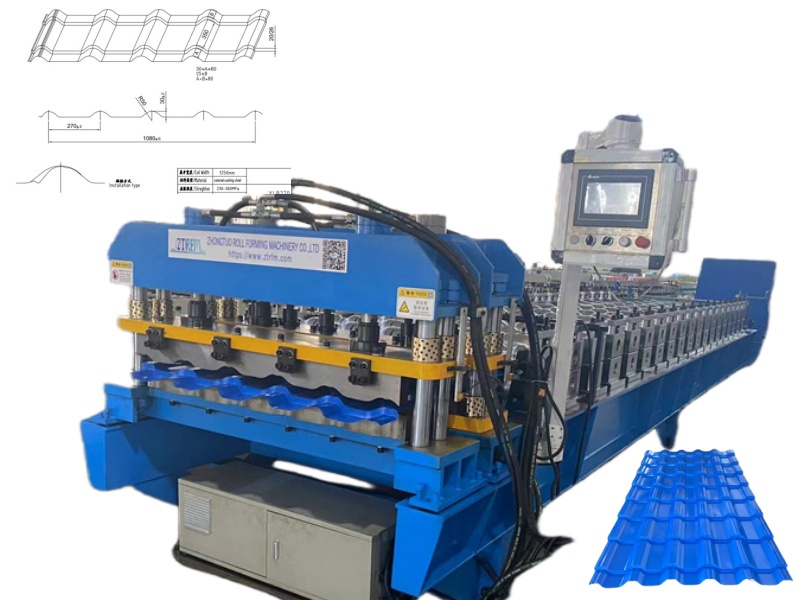

Double-Layer Ridge Capping Roll Forming Machine In modern roofing construction, ridge caps play a critical

Mangalore Tile Profile Sheet Roll Forming Machine Overview of Mangalore Tile Profile Sheet Roll Forming

Metal Ridge Capping Making Roll Forming Machine Efficient, Accurate & Worry-Free Roofing Profile Machine The

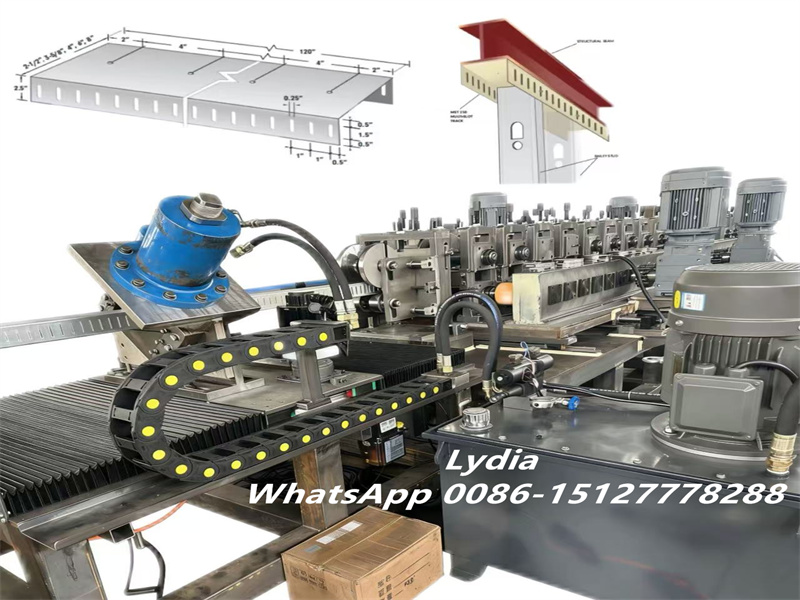

C Channel Light Steel Keel Stud and Track Roll Forming Machine High-Precision Drywall CU/CW Profile

STAY IN THE LOOP