R-panel and AG panel are both two different popular mental wall and roof panels. But sometimes it is difficult to distinguish that which kind of panel is the best to users for application, due to the similarity.Both panels are manufacture by tens,hundreds of companies ,and they are not created equal because they are different characteristic and applications in level of quality and appearance .

When it comes to the steel substrate and paint system that is utilized ,R-panels and Ag panels show them difference more obviously.

What is AG-panel

AG-panel is one of the most popular exposed fastener mental roofing in construction industry.

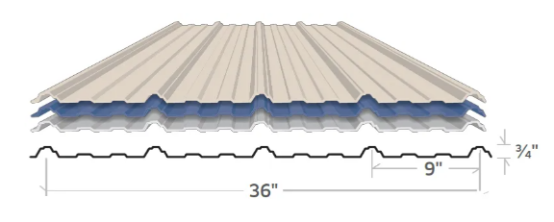

Even if there are little different details or inch, the panel drawing basically show the most popular panel model today.

It is about 3/4’’ deep,and the distance between two peak is 9’’,and provide 36’’ coverage. Some people refer to as “pole barn steel ”

What is R-panel

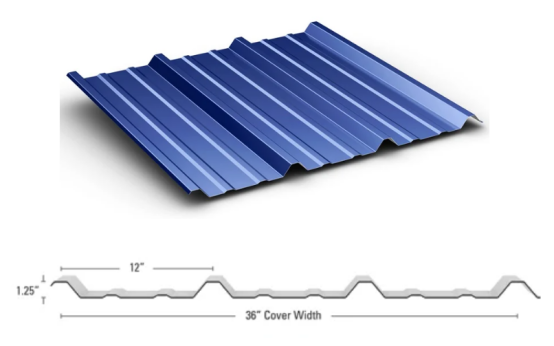

panel is also an exposed fastener metal roofing and metal wall that pressed strong ribs as a main peak, and there are two reinforce ribs between two peak.

It is 1.25’’deep and 12’’width from each high corrugation,36’’ of coverage is provided.

R-Panels & PBR Panels are designed primarily for commercial, industrial and steel frame building applications.

What is The Differences between R-panel and Ag panel

1. the difference of appearance

From the appearance, each wave of the R -plate is quite different from the peak of the Ag- plate.

The peak of the AG plate is sharp like a mountain peak, while the peak of the R-panel is more flat .

(AG-panel application )

(R-panel application )

In some ways, the visual appearance of the panel is the biggest difference between in two panel types ,which is why the final decision come from the personal preference .

In the Texas and southwest where “bold is beautiful” they pretend to chose a bold appearance like R -panel ,while other people will prefer another .

2.R-Panel Is A Stronger Panel

The higher the rib height, the stronger the panel. R Panel features ribs that are 1 ¼” high while AG Panel’s ribs are only ¾” high.

The higher ribs make R Panel the stronger metal panel of the two.

And the gauge size also affect the strong of the panel , 26 gauge is a standard gauge for R -panel while the Ag-panel is 29 gauges. As the gauge number become higher ,the metal thickness become thin and less durable , as same ,the 26 gauge size is surely stronger than 29 gauge size .

In some western states in American , we don’t recommend to use Ag panel of 29 guage size for paving roofing .even the Ag panel can save the cost of material of 5 percent to 10 percent. The lighter gauge Ag panel will be far less durable and more susceptible to weather damage. When you look at the overall installed cost of your Ag panel metal roof ,it amounts to very little savings.

3. the availability of two kind of panels .

R-Panel enjoys higher popularity and greater availability, making it a breeze to source. Whether you’re browsing at major retailers like Home Depot or purchasing directly from manufacturers, R-Panel is typically in stock. In contrast, AG Panels can be more challenging to find. If your project has a strict deadline and you need to secure materials promptly, R-Panel is the clear choice over AG Panel, as its widespread presence ensures you can quickly obtain the product without delays.

4. the example on application

In order that we understand R-Panel and AG Panel differences, let’s take a look at how metal buildings and post frame buildings are different. Metal buildings are supported with steel structural and substructural members while post frame buildings are supported with wood structural and sub-structural members.

Pre -Engineered Metal Building

Post Frame Building

When aiming to minimize the use of framing materials, increasing the distance between framing members is a practical approach. R-panel, constructed from 26-gauge steel—a notably thick material—and featuring sturdy major ribs, offers enhanced strength and load-bearing capacity. These attributes allow R-panel to cover larger spans between framing components. In certain climates, the sub-structural spacing of pre-engineered metal buildings can reach up to 5 feet from the center of one framing member to the next.

Conversely, post-frame buildings typically have roof framing spaced at 2 feet on center. This closer spacing reduces the stress on the roofing material, enabling the use of a lighter-gauge panel with less robust major ribs to meet engineering requirements. As a result, Ag Panels have become the preferred choice for post-frame buildings, balancing structural integrity with cost – effectiveness.

In brief R-panel is a better choice to be installed on a over open frame with a greater center spans.if the panel will to be installed on a more solid deck frame ,such as the residential roofing ,the difference strength has a less impact . At this time ,while the 26 guage R panel is stronger than a 29 guage Ag panel, using a way of fastening attachment can make up the short on the strong of panel.

In the southwest states , R panel is common used for residential , the final use contain the residential metal roofing and building such as some living , work and sport relaxation area .

the most common practice is to use an R-Panel if the structure is a pre engineered metal building and use an Ag-Panel if the structure is a post frame building.

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP