DIN Rail Roll Forming Machine Automatic DIN Rail Channel Making Line

What is DIN Rail?

DIN rail channel (Deutsche Industrie Normen rail) is a standardized metal profile widely used in electrical equipment mounting, control panel assembly, power distribution boxes, telecommunication systems, and solar PV installations.

Din Rail Roll Forming Machine

DIN rail provides a reliable, standardized, and cost-effective solution for installing circuit breakers, relays, terminal blocks, PLCs, inverters, and other devices across industrial automation, commercial electrical cabinets, and residential energy systems.

Technical Specifications of High-Speed DIN Rail Channel Making Machine for Electrical Equipment

| Item | Specification |

|---|---|

| Suitable Material | HCR Coil / Carbon Steel / GI Coil |

| Material Thickness | 0.6 – 2.0 mm |

| Profile Size | 35 mm (customized DIN rail profiles) |

| Line Speed | 0 – 20 m/min (high-speed DIN rail production) |

| Cutting Type | Hydraulic shear, SKD11 cutting knife |

| Control System | PLC + Encoder + Touch Screen |

| Power Supply | Customized based on requirements |

Production Flow

Steel Coil → Uncoiler Straightener 2 in 1 → Servo Feeder → Guide Device → Hydraulic Punch → Roll Forming Machine → Hydraulic Shear Device → Finished Product Rack → PLC Control

Global Market of DIN Rail Roll Forming Machine

The DIN Rail Channel Machine has been widely adopted in countries such as Germany, the United States, France, Italy, India, Indonesia, and China.

Din Rail Roll Forming Machine

ZTRFM DIN Rail Roll Forming Machine

The ZTRFM DIN Rail Roll Forming Machine provides automatic DIN rail channel manufacturing with high speed, precision, and durability.

Din Rail Roll Forming Machine

Complete Line Configuration

| No. | Equipment | Quantity | Function |

|---|---|---|---|

| 1 | Uncoiler & Straightener 2 in 1 | 1 unit | Coil feeding & leveling for DIN rail production |

| 2 | Servo Feeder | 1 unit | High-precision coil feeding |

| 3 | Guide Device | 1 unit | Ensure DIN rail profile alignment |

| 4 | Hydraulic Punching Press | 1 set | Punching slots & holes on DIN rail |

| 5 | Roll Forming Machine | 1 set | Roll forming DIN rail channel shapes |

| 6 | Hydraulic Shear Device | 1 unit | Precision cutting with SKD11 blade |

| 7 | Finished Product Rack | 1 unit | Collect finished DIN rail profiles |

| 8 | Hydraulic Station | 1 unit | Provide hydraulic power |

| 9 | Electric Control Panel (PLC) | 1 unit | PLC automation & encoder length control |

Din Rail Roll Forming Machine

Applications of DIN Rail Roll Forming Machine

- Electrical Control Panels & Cabinets

- Power Distribution Systems

- Telecommunication Racks & Networking Devices

- Renewable Energy & Solar PV Systems

- Industrial Automation Equipment

The ZTRFM DIN Rail Roll Forming Machine is a cost-effective and high-speed solution for DIN rail channel manufacturing. With its automatic production line, precision hydraulic cutting, and PLC control system, it ensures consistent quality and efficiency for the electrical, telecom, and energy industries worldwide.

Din Rail Roll Forming Machine

Din Rail Roll Forming Machine

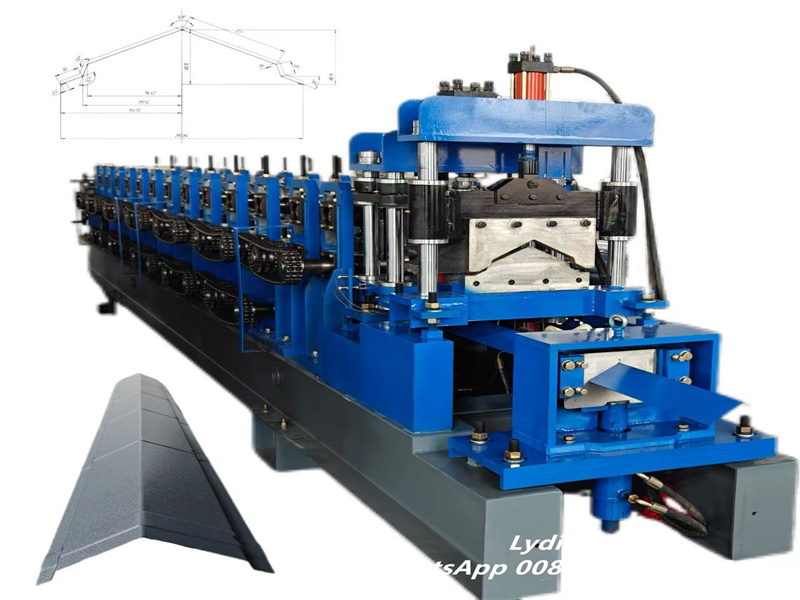

Double-Layer Ridge Capping Roll Forming Machine In modern roofing construction, ridge caps play a critical

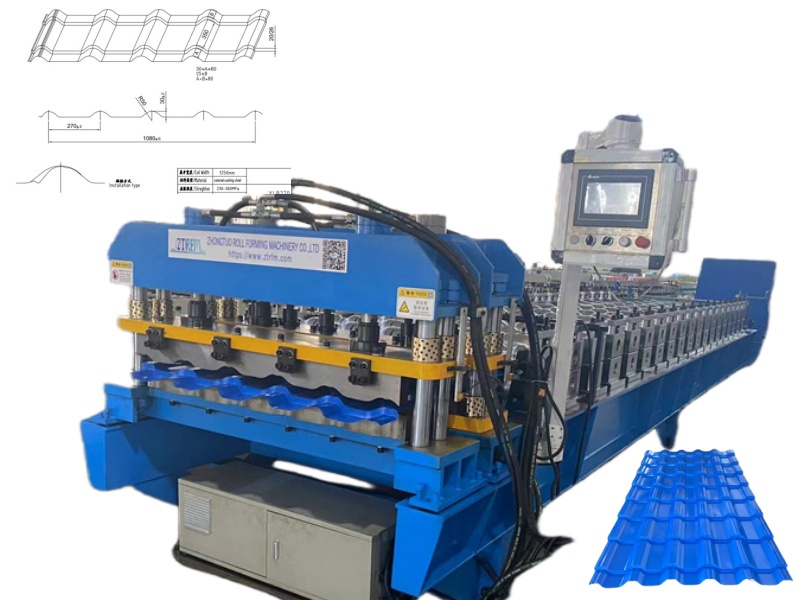

Mangalore Tile Profile Sheet Roll Forming Machine Overview of Mangalore Tile Profile Sheet Roll Forming

Metal Ridge Capping Making Roll Forming Machine Efficient, Accurate & Worry-Free Roofing Profile Machine The

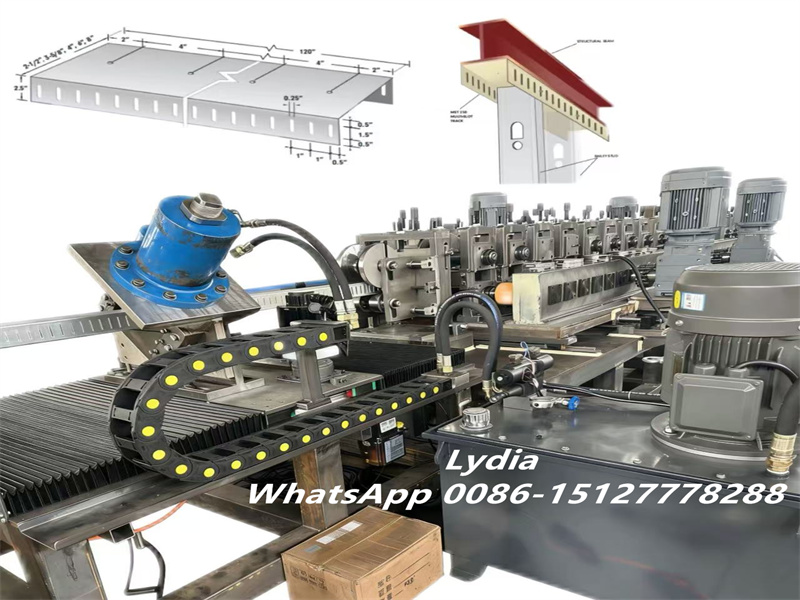

C Channel Light Steel Keel Stud and Track Roll Forming Machine High-Precision Drywall CU/CW Profile

STAY IN THE LOOP