Product Overview of Hydraulic Press Brake Machine

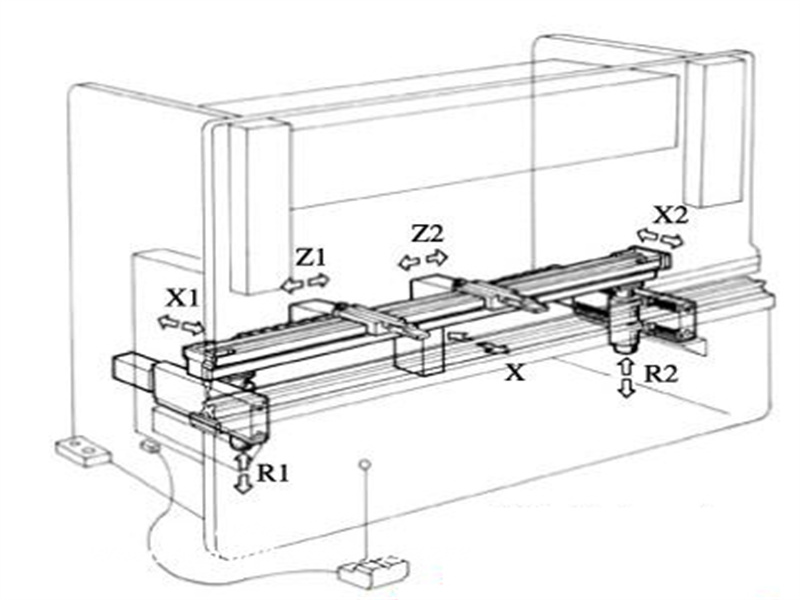

The ZTRFM 400T4000 CNC Electro-Hydraulic Press Brake is a high-precision, fully automatic bending machine designed for modern sheet metal processing. With 400T nominal pressure, 4,000 mm bending length, and a 4+1 axis configuration (Y1, Y2, X, R + V), it delivers superior accuracy, flexibility, and productivity.

Hydraulic Press Brake

Equipped with the advanced Holland DELEM DA53TX CNC control system, this press brake offers intuitive touch programming, high-resolution TFT display, and powerful automation functions. It is ideal for heavy-duty bending applications across industries such as construction, automotive, and metal fabrication.

Hydraulic Press Brake

Key Specifications of Hydraulic Press Brake Machine

| Item | Details |

|---|---|

| Model | 400T × 4000 mm CNC Press Brake |

| Type | Electro-Hydraulic, Fully Automatic |

| CNC System | Holland DELEM DA53TX |

| Bending Length | 4,000 mm |

| Nominal Pressure | 4000 kN (400T) |

| Worktable Length | 4,000 mm |

| Distance Between Uprights | 3,500 mm |

| Throat Depth | 400 mm |

| Ram Stroke | 250 mm |

| Max Opening Height | 580 mm |

| Axis | 4+1 (Y1, Y2, X, R + V) |

| Stroke Speed | Approach: 100 mm/s Working: 8 mm/s Return: 100 mm/s |

| Main Motor | Siemens / Wannan, 30 kW |

| Pump | SUNNY CPO 63 Series |

| Size | 3800 × 1850 × 2550 mm |

| Weight | 23,000 kg |

| Oil Tank | 450 L, 46# anti-wear hydraulic oil |

Hydraulic Press Brake

Standard Configuration of the Machine

CNC Control System (DA53TX)

-

15″ high-resolution color TFT touch screen

-

Numerical touch programming

-

Servo and inverter control

-

Automatic crowning system (V-axis)

-

USB peripheral interfacing & offline software support

Back Gauge

-

X & R axis (ball screw + linear drive, HIWIN/TBI)

-

Accuracy: ±0.03 mm (X axis), ±0.05 mm (R axis)

-

Speed: X axis 350 mm/s, R axis 120 mm/s

Hydraulic & Power System

-

German Rexroth / Argo hydraulic system

-

USA SUNNY pump

-

Siemens/Wannan main motor

-

Japan NOK seals

-

High-quality hydraulic cylinders & soft hoses

Mechanical Parts

-

Italian GIVI / Spain FAGOR grating ruler

-

Standard upper & lower tools (heat-treated, quick-release clamp, goose-neck type, multi-V bottom die)

-

Tempered machine frame for long-term rigidity

Servo System

-

INOVANCE servo motor & drive (Japan)

Crowning System

-

High-precision automatic crowning system, CNC-controlled

Hydraulic Press Brake

Hydraulic Press Brake

Manufacturing Excellence

-

Machine Frame: Stress-relieved, tempered frame for long-term rigidity

-

Precision Machining: Machined to grinding tolerance (0.05–0.01 mm) ensuring bending accuracy and parallel Y1/Y2 axis control

-

Workshop Capability: Modern CNC machining centers guarantee high accuracy, durability, and stability during production

The ZTRFM 400T4000 CNC Electro-Hydraulic Press Brake combines precision, strength, and innovation, making it the perfect solution for manufacturers seeking reliability and productivity in metal bending applications.

Hydraulic Press Brake

Hydraulic Press Brake

Double-Layer Ridge Capping Roll Forming Machine In modern roofing construction, ridge caps play a critical

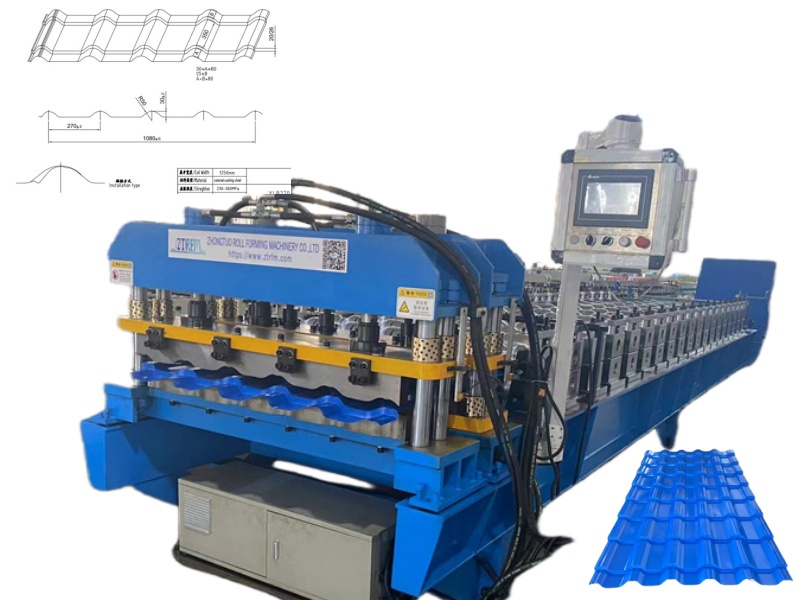

Mangalore Tile Profile Sheet Roll Forming Machine Overview of Mangalore Tile Profile Sheet Roll Forming

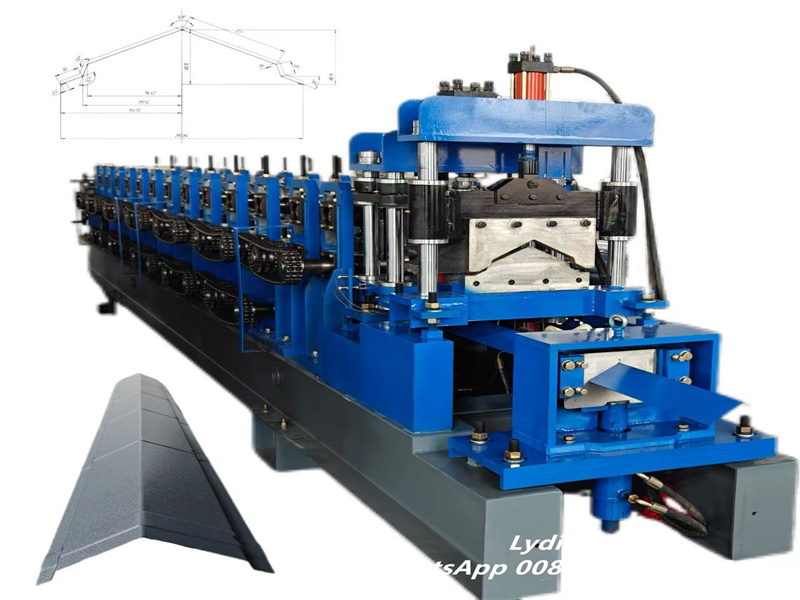

Metal Ridge Capping Making Roll Forming Machine Efficient, Accurate & Worry-Free Roofing Profile Machine The

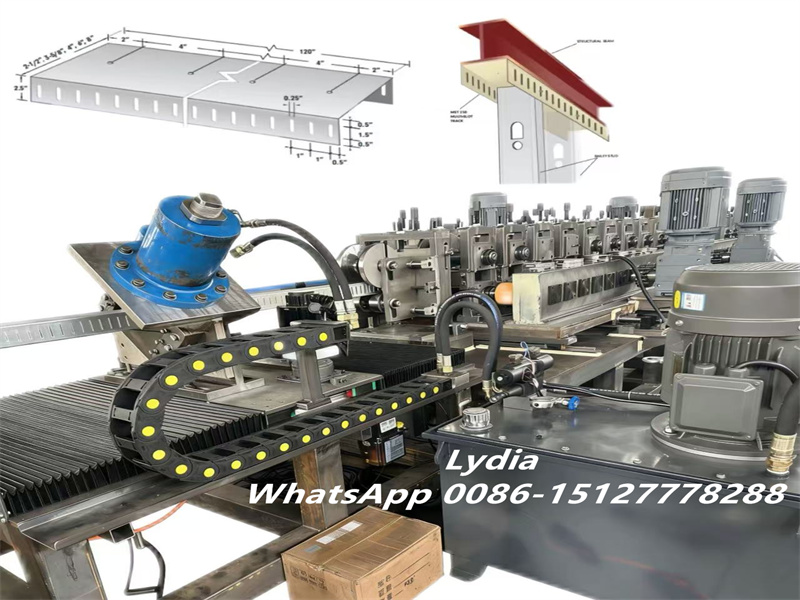

C Channel Light Steel Keel Stud and Track Roll Forming Machine High-Precision Drywall CU/CW Profile

STAY IN THE LOOP