Usage: When feeding a coil, as the material thickness reaches up to 3.0mm, it becomes quite heavy. With this device, we can feed the coil easily and in the right direction.

Metal Embossing Machine Line for Sheet and Coil Applications

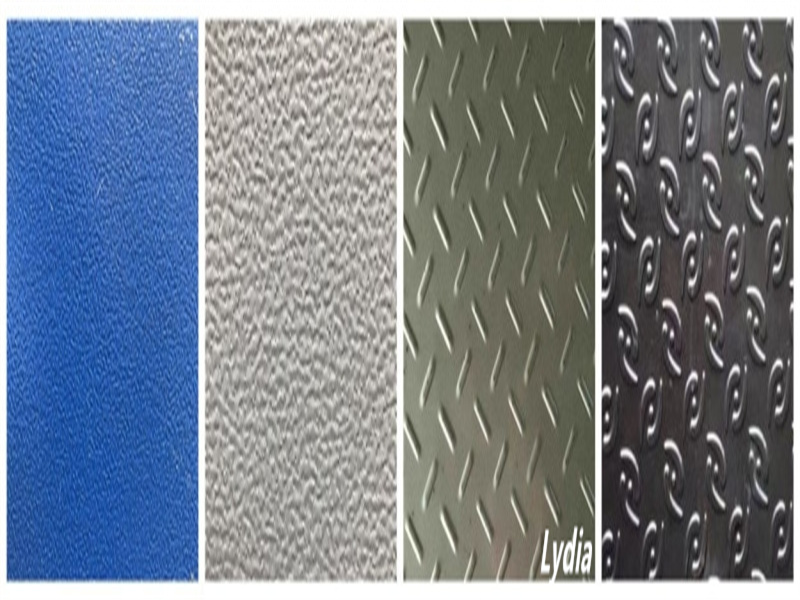

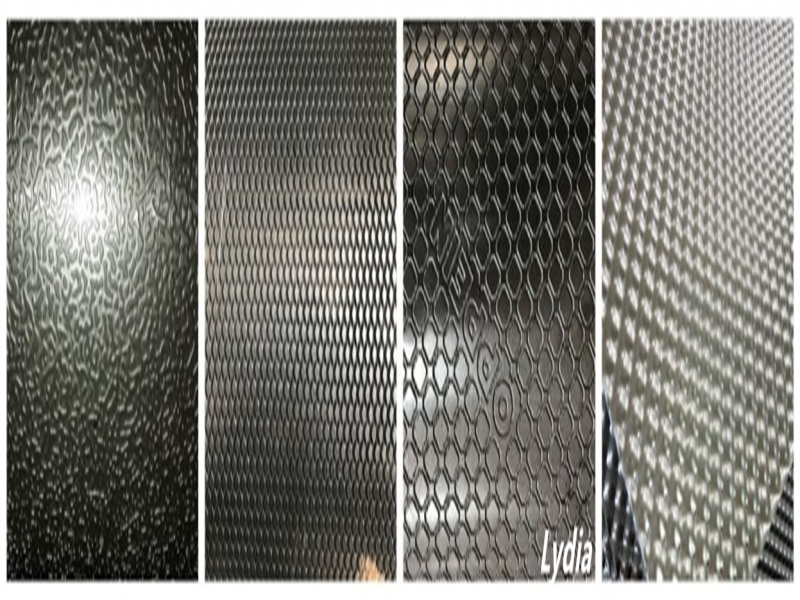

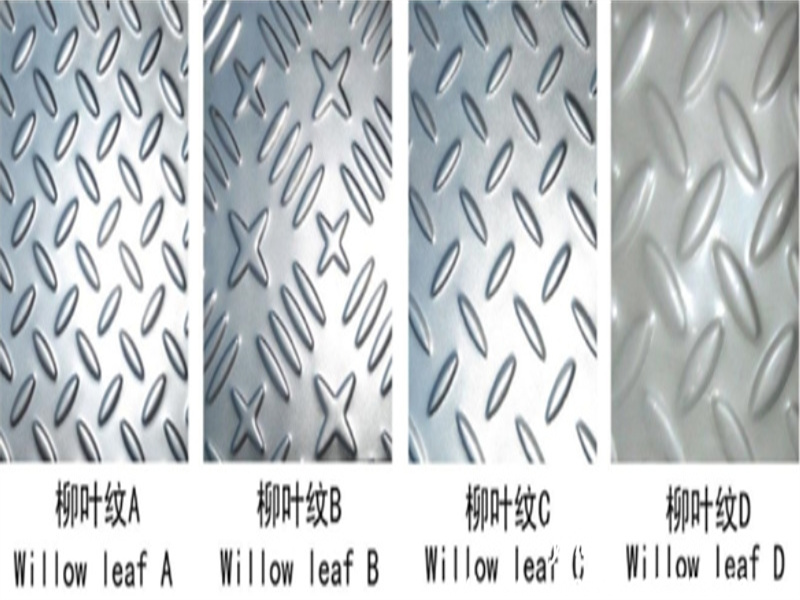

A metal embossing machine line is a specialized metal forming system designed to create continuous straight or parallel ridges on metal sheets or strips, enhancing both appearance and structural integrity. The metal coil embossing process forms various decorative or functional patterns on metal sheets by passing them through engraved rollers. Suitable for sheet thicknesses ranging from 0.2 mm to 5.0 mm, this process can be performed as a standalone embossing operation or integrated into a roll forming line. For complete automation, the embossing production line typically consists of an uncoiler, the embossing machine, and a recoiler.

Beyond aesthetics, one key benefit of embossing is the significant improvement in the sheet’s strength-to-weight ratio. This allows manufacturers to use thinner gauge material while still meeting structural performance requirements. Embossing can be achieved through stamping or rolling, with rolling being the preferred method due to its efficiency. Rotary rollers continuously imprint patterns, allowing for much higher production speeds than stamping.

Embossing Machine

Key Technical Specifications

1. The embossing rollers are forged from solid steel, hardened through heat treatment, and achieve a surface hardness of HRC 55°–60°.

2. Standard embossing roller dimensions are Ø410 mm × 1300 mm. Suitable material thickness ranges from 0.2 mm to 1.6 mm, with adjustable embossing depth to meet varying design needs.

3. Powered by a 15 kW Shunbai-brand motor (Chinese brand), coupled with a custom-designed reducer to ensure stable performance.

4. The machine frame is fully welded with a solid, integrated structure. The main body sides have a wall thickness of 110 mm for enhanced durability.

5. Roller pressure is adjusted via a screw mechanism and worm gear box, allowing manual fine-tuning of pressure on both sides. An adjustment scale provides a reference for consistent settings.

6. The typical working speed is 15 meters per minute, with adjustable speed control as needed.

7. Speed regulation is managed by a Delta-brand frequency inverter.

Embossing Machine

| Item | Specification |

|---|---|

| Machine Type | Embossing machine for 3D wall panel production |

| Embossing Roller Size | Ø440 × 1150 mm |

| Material of Embossing Roller | 60CrMnMo |

| Roller Surface Hardness | HRC 58 ~ 62 |

| Depth of Hardened Surface | 5 – 10 mm |

| Bearing Box Size | 400 × 400 × 160 mm |

| Driving Motor | 11 kW AC motor |

| Reducer | BWED53-17×11 – 11 kW 4P |

| Working Speed | 1 – 10 m/min |

| Pressure System | Hydraulic system |

| Oil Cylinder Specifications | Ø150 mm, 2 pcs |

Embossing Machine

Embossing Machine

Embossing Machine

Embossing Machine

Engineered by Zhongtuo for Precision and Surface Protection As patio and pergola structures become more

Zhongtuo Industrial Cable Tray Roll Forming Production Line Zhongtuo Cable Tray Roll Forming Machine is

Full Automatic Steel Supermarket Shelves Storage Rack Upright Pillar Roll Forming Machine Improve Warehouse Efficiency

Cable Ladder & Cable Tray Roll Forming Machine High-Efficiency Steel Side Rail Forming Machine for

STAY IN THE LOOP