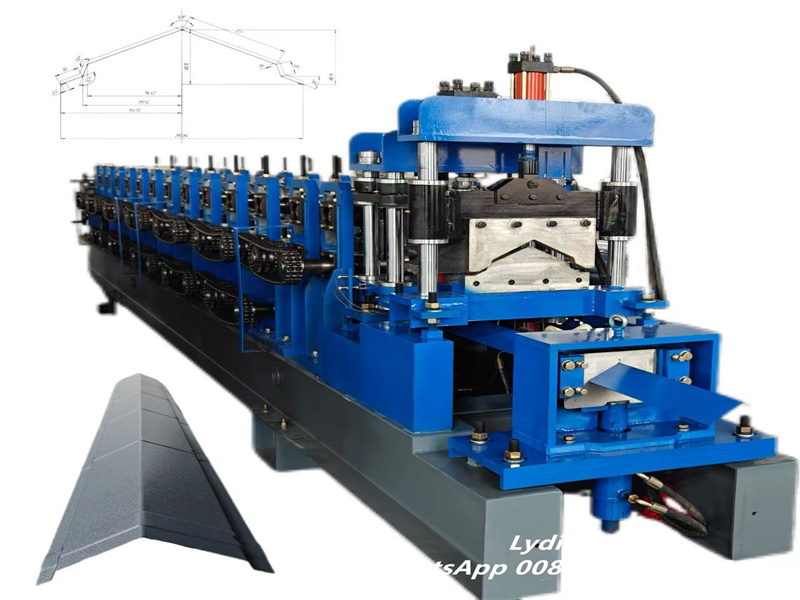

Z Purlin Roll Forming Machine Overview

Upgrade your steel profile production with our Z Purlin Roll forming Machine, engineered for full automation, rapid size changes, and precise tolerances. Designed to handle Z-section purlins from Z100 to Z300 (100 mm–300 mm width) and steel coil thicknesses of 1.2 mm–3.0 mm, this system integrates decoiling, leveling, pre-punching, roll forming, and cutting into one compact line. Whether you manufacture roof purlins for warehouses, agricultural buildings, or prefab structures, this z purlin machine delivers consistent, high-speed output to maximize your return on investment.

Key Features of the Z Purlin Machine

1. Fully Automatic Size Adjustment

- Touch-Screen Control: Change profile widths between Z100 and Z300 with preset recipes on an intuitive HMI.

- Servo-Driven Actuators: Complete width adjustments in under 60 seconds—no manual tools required.

2. Multi-Speed Production

- Variable Forming Speeds: Choose 8 m/min for heavy-gauge runs, 16 m/min for standard batches, or 25 m/min for high-volume, thin-gauge production.

- VFD Integration: Smooth acceleration and precise speed control protect tooling life and ensure straight profiles.

3. Integrated Punching & Cutting

- Programmable Punching Unit: Hydraulic pre-punch holes (round, oblong, or custom shapes) at intervals up to 2 m.

- Fly-Cut Shear: Servo-synced cutting maintains line speed without stopping, delivering burr-free ends.

4. Robust Mechanical Design

- 18-Station Roll Forming Section: Hardened GCr15 rollers mounted on precision bearings for long service life.

- Heavy-Duty Frame: 400×400 H-beam welded base, shot-blasted and painted to resist corrosion and vibration.

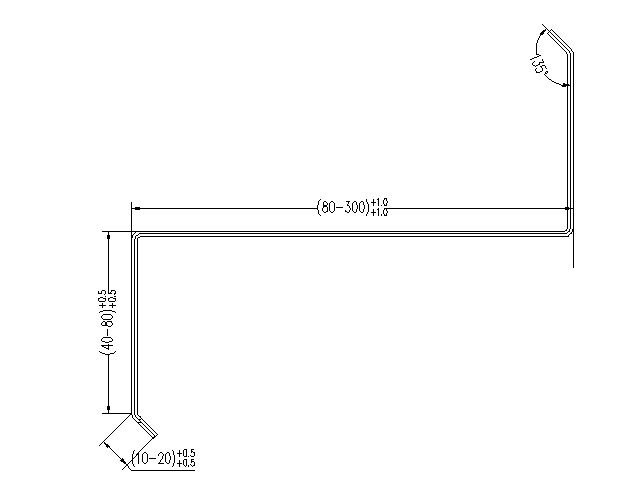

The Drawing Profile Z Purlin Machine

Z Purlin Machine Configuration Details

| Module | Specification |

| Decoiler | 3 T manual/hydraulic |

| Leveler | 7-roller solid-shaft unit |

| Forming Stations | 18 stations, GCr15 shafts |

| Drive System | PLC with Siemens/Delta servo motors |

| Control Panel | 12″ HMI touchscreen, multilingual support |

| Punching Unit | Hydraulic, programmable spacing |

| Cutting System | Hydraulic fly-cut shear, servo-synchronized |

| Support Tables | 4 m adjustable in-feed and out-feed tables |

Benefits of Investing in a Z Purlin Roll forming Machine

- Increased Throughput: Fast changeovers and high line speeds minimize downtime, boosting your daily output.

- Superior Quality Control: CNC-level precision keeps section dimensions within ±0.1 mm across long runs.

- Labor Savings: Automated setup, punching, and cutting reduce manual intervention and operator fatigue.

- Production Flexibility: Seamlessly switch between multiple Z-profile sizes without tooling swaps or lengthy re-adjustments.

- Lower Total Cost of Ownership: Heavy-duty components, buffered torque transmission, and preventive maintenance plans extend machine life.

Typical Applications for the Z Purlin Machine

- Industrial & Commercial Roofing: Durable roof purlins for large-span warehouses and factories.

- Prefabricated Buildings: High-strength secondary steel members for quick-assembly structures.

- Agricultural Barns & Sheds: Lightweight support frames resistant to corrosion and load stress.

- Cold Storage & Logistics Facilities: Consistent, straight purlins for impermeable wall and ceiling panels.

After‑Sales Support for Your Z Purlin Roll Forming Machine

- Commissioning & Training: On-site start-up assistance plus operator and maintenance workshops.

- Spare Parts Guarantee: Regional stocking of critical components—rollers, hydraulic seals, PLC modules.

- Preventive Maintenance Contracts: Scheduled inspections, software updates, and performance tuning.

- 24/7 Technical Hotline: Rapid troubleshooting and remote diagnostics to keep your line running.

Contact us today to discuss customization options, request a live demo, or receive a personalized quotation. Let our z purlin machine become the backbone of your steel construction business.

Double-Layer Ridge Capping Roll Forming Machine In modern roofing construction, ridge caps play a critical

Mangalore Tile Profile Sheet Roll Forming Machine Overview of Mangalore Tile Profile Sheet Roll Forming

Metal Ridge Capping Making Roll Forming Machine Efficient, Accurate & Worry-Free Roofing Profile Machine The

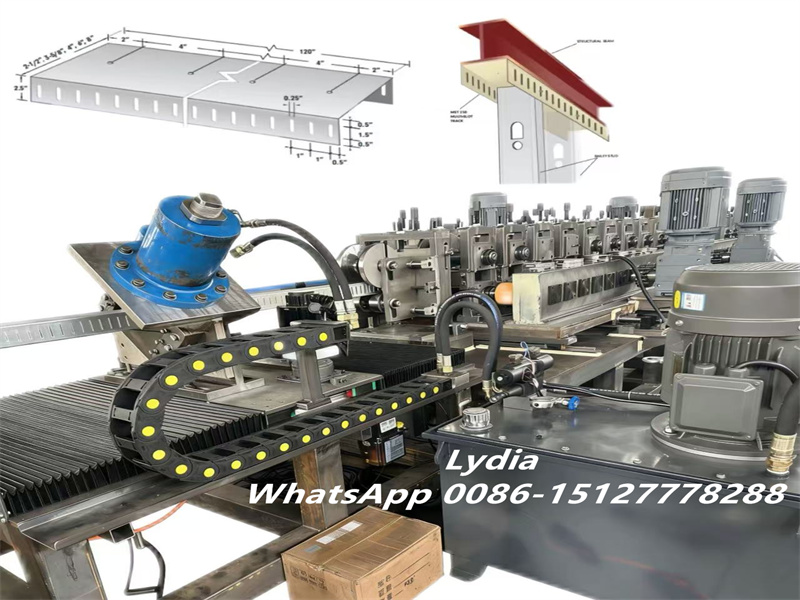

C Channel Light Steel Keel Stud and Track Roll Forming Machine High-Precision Drywall CU/CW Profile

STAY IN THE LOOP