Standard Features:

– Powered by a hydraulic drive system with a front scissor shear for seamless hydraulic operation.

– Equipped with a 3 HP electric-hydraulic power unit, operating on a 220V single-phase connection.

-Adjustable panel widths, ranging from 10″ to 24″, to accommodate varying requirements.

– Production speed reaches 30 meters per minute, ensuring efficient output.

– Compatible with materials such as 24-gauge steeland 12-16 oz copper.

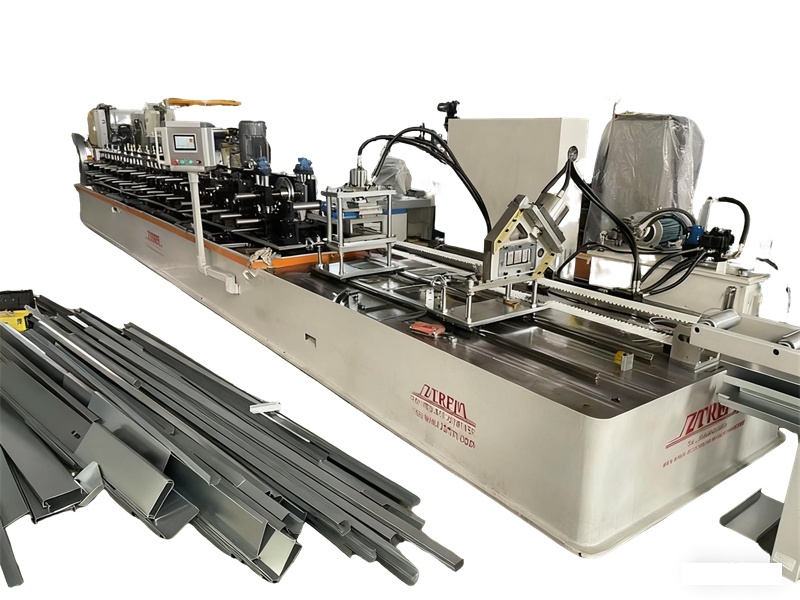

Our soffit panel production lines are engineered to deliver exceptional efficiency in manufacturing top-quality soffit panels. Whether your needs require medium-volume or high-volume production, ZTRFM offers solutions tailored to your requirements.

Our customizable lines provide flexibility, allowing you to choose between feed-to-stop systems or high-speed flying post-cut operations, ensuring adaptability to your specific production demands.

With ZTRFM’s specialized lancing pass, you can produce flat, center-vented, or fully vented panels, offering the versatility needed to satisfy diverse customer preferences.

Upgrade to an ZTRFM Soffit Panel Line today and experience unmatched value and premium quality.

ROLLFORMER Features:

– Entry guide with an optional handwheel for enhanced precision.

– Durable cast rollformer stands and bearing blocks for long-term reliability.

– Micrometer dials for precise adjustments.

– Precision-ground shafts ensuring consistent performance.

– Equipped with an AC positioning motor for accurate operation.

– Chain drive or gearbox drive systems available.

– OSHA-compliant safety guarding to enhance workplace safety.

ROLLER TOOLING Specifications:

– Designed and manufactured in-house for superior quality control.

– Proprietary computerized tooling design for optimized performance.

– Crafted from #45 steel with a hard chrome finish, annealed or D2 tooling for durability.

– Machined steel tooling spacers eliminate the need for set collars.

– Optional split spacers for quick changeover to support 3- or 4-rib soffit panel profiles.

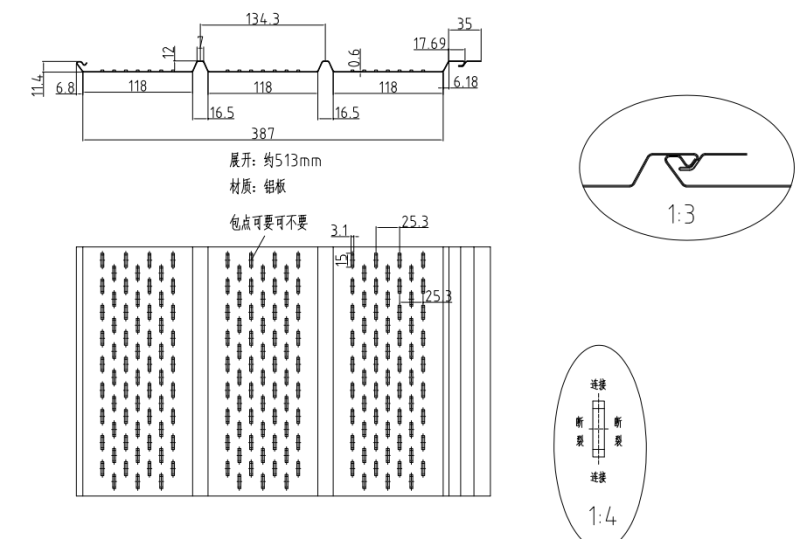

Profile Drawing:

The Technical Specifications Of The Soffit Panel Machine:

| NO | Name | Specifications |

| 1 | Raw material | Aluminum, PPGI |

| 2 | Raw material thickness | 0.3-0.5mm(22-26 gauge) |

| 3 | Decoiler | 5T Hydraulic decoiler(Different capacity for option,manual one for option) |

| 4 | Roller station | 22 stations |

| 5 | Roller material | 45# steel with quenched treatment |

| 6 | Shaft diameter | 70mm |

| 7 | Work speed | 0-30m/min |

| 8 | Transmission | by single chain transmission |

| 9 | Motor power | 7.5kw motor |

| 10 | Machine frame | 350# H steel welded |

| 11 | Cutting type | Hydraulic fly cutting |

| 12 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | GB-Cr12 |

| 15 | Hydraulic motor power | 5.5KW |

| 16 | Control system | PLC |

| 17 | Brand | PLC:Delta/Siemens/Mitsubishi

Touch screen:Delta/Siemens/Mitsubishi Encoder:Omron |

The ZT-1250 sheet metal folding machine is designed for bending metal sheets up to 1250

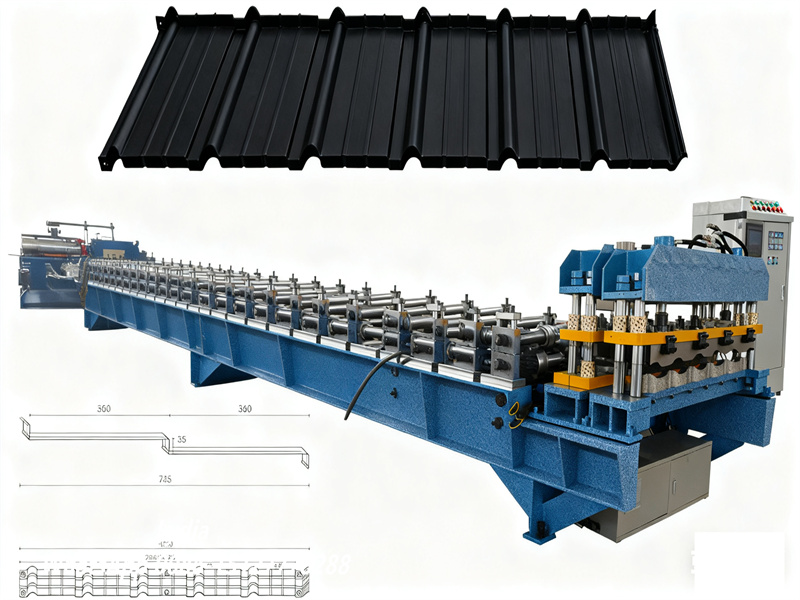

Color Steel Roof Tile Roll Forming Machine High Precision & Efficient Production Line The Color

Width Adjustable Metal U Channel Steel Lining Profile Rolling Machine The Width-Adjustable Metal U-Channel Steel Lining

Lift Table Method for Roll Forming Machine Stacking Systems In modern roll forming production lines,

STAY IN THE LOOP