Cut To Length Line Machine Technical Parameter:

(1) Outer diameter of coil: maxF1600mm

(2) Inner diameter of coil: F508mm

(3) Maximum working speed: 60m/min

(4) Equipped with anti-releasing pressure arm: 1 pc

(5) Reel expansion and contraction range: F470~F530mm

(6) Spindle diameter: Φ232mm

(7) Effective length of reel: 1650mm

(8) Drive motor: 7.5KW

Cut To Length Line:

This cut to length line machine features a high-precision rack and guide rail transmission system, combining advanced numerical control (CNC) technology with a state-of-the-art fiber laser cutting mechanism. As a high-tech product, it integrates laser cutting, precision machinery, and CNC technology to deliver superior performance. The machine’s leveling and cut-to-length line exhibits excellent dynamic characteristics, achieving high cutting efficiency. It is equipped with a specialized CNC system that is powerful, intuitive, and user-friendly, making it an ideal choice for the processing of various metal materials.

Primarily designed for the cutting and forming of metals such as carbon steel, stainless steel, alloy steel, spring steel, galvanized sheets, copper sheets, aluminum sheets, and other metallic plates, cut to length line machine offers precise and efficient processing capabilities. Its robust design and advanced features make it a top selection for industries requiring high-quality metal fabrication.

The core operation of cut to length line machine involves several steps: unwinding the coil, leveling the material, cross-cutting it to the desired length, stacking the cut sheets, and finally packaging them for delivery.

ZTRFM offers a variety of shearing technologies, including rotary, flying, and stop/start shears, as well as multiple stacking solutions such as bomb-door, air-blow, combined drop-airblow, and sliding systems. Their state-of-the-art roller leveler and stretch leveling technologies are designed to deliver optimal results in both precision and performance.

cut to length Machine

cut to length Machine

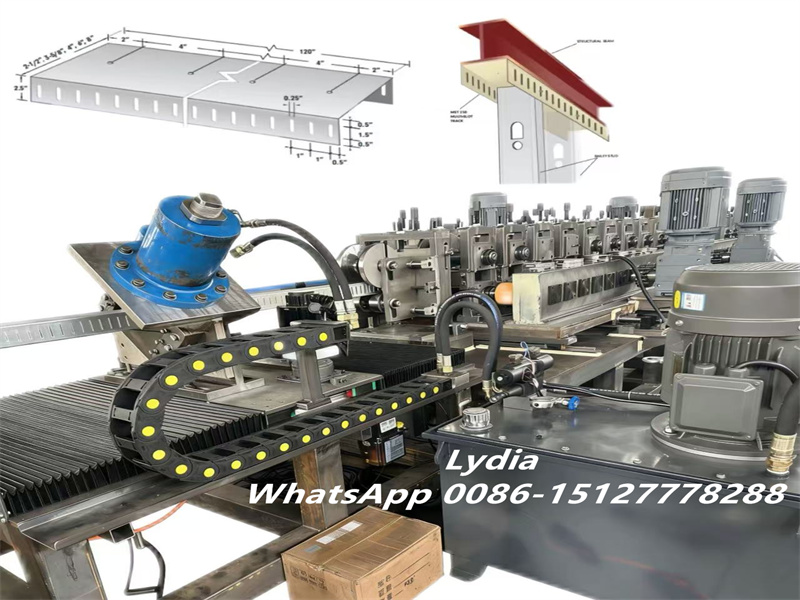

Metal Ridge Capping Making Roll Forming Machine Efficient, Accurate & Worry-Free Roofing Profile Machine The

C Channel Light Steel Keel Stud and Track Roll Forming Machine High-Precision Drywall CU/CW Profile

Top Hat Roll Forming Machine The Top Hat Roll Forming Machine is a high-performance production

Container house frame making machine Australian specification standards shipping living container house frame making machine is

STAY IN THE LOOP