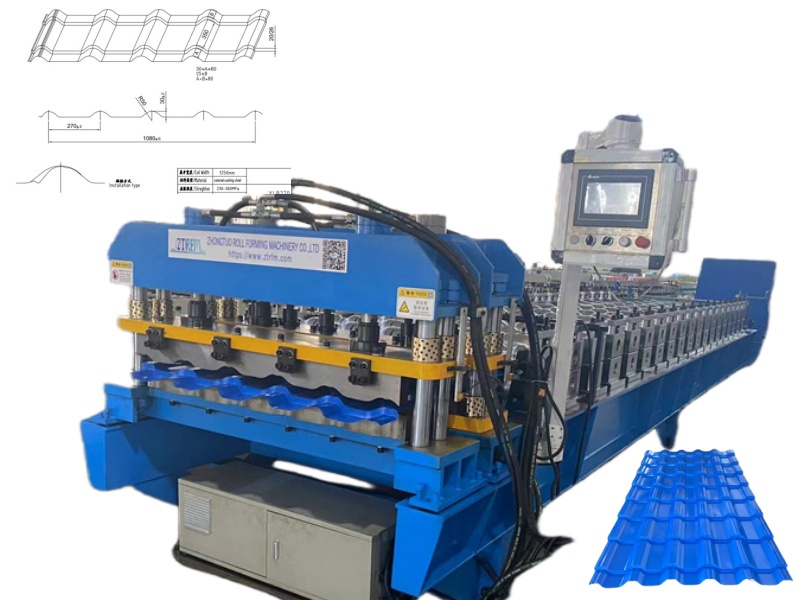

High-Speed Metal Roof Corrugated Sheets Rolling Forming Machine (45m/min)

The Metal Roof Corrugated Sheets Rolling Forming Machine is a high-performance production line designed for manufacturing lightweight, durable, and precisely formed roofing sheets.

With a speed up to 45 meters per minute, it is ideal for large-scale industrial roofing projects and global construction applications.

Metal Roof Corrugated Sheets Rolling Forming Machine

Corrugated metal roofing is widely used worldwide because it is easy to install, weather-resistant, lightweight, and strong under load. To meet growing market demand, our engineering team has developed an upgraded automatic corrugated sheet roll-forming solution with servo-cutting and high-speed gearbox transmission.

Key Technical Parameters of Metal Roof Corrugated Sheets Rolling Forming Machine

| Item | Specification | Description / Advantages |

|---|---|---|

| Material Type | GI, PPGI, GL, PPGL | Galvanized or color-coated steel coil |

| Material Thickness | 0.18 – 0.45 mm | Suitable for thin sheets without surface damage |

| Working Speed | 0–45 m/min | Controlled by a frequency inverter and a servo cutting |

| Forming Stations | 22 stations | Separate rolling design for smooth and accurate shaping |

| Shaft Diameter | 80 mm | 40Cr steel, tempered for strength |

| Roller Material | 45# steel with 0.05mm chrome | Smooth surface, anti-corrosion, long lifespan |

| Transmission System | Gearbox (Bevel Gear) | Fast and stable drive after cutting |

| Main Power | 2 × 7.5 kW | Twin motors for continuous high-speed operation |

| Machine Frame | H-Beam Structure | Rigid design with vibration stress relief |

| Cutting System | Servo Tracking Saw | Accurate cutting at full speed |

| Decoiler | Hydraulic Type (5T/10T) | Optional with or without loading car |

| Stacker Options | Front/Back or Left/Right Discharge | Flexible layout for workshop space |

| Operator Requirement | 1 Person | Fully automatic production line |

Machine Highlights

Machine Highlights

1. Adjustable Feeding Platform

The hand-wheel adjustable feeding table ensures precise coil alignment and protects edges from scratches during high-speed feeding.

2. Separate Rolling Concept

Each forming station independently releases internal stress from the sheet, keeping the final product smooth and uniform.

3. Rigid Structural Frame

The welded H-beam frame undergoes vibration aging treatment and surface planing to guarantee long-term accuracy and stability.

4. Durable Roller System

All rollers are made of GCr15 or 45# steel, polished and chromed, ensuring a mirror-smooth finish and long service life.

Metal Roof Corrugated Sheets Rolling Forming Machine

Why It Can Handle Thin Sheets (0.18–0.45mm) Smoothly

- The roller shape is smoothly curved instead of triangular, preventing surface deformation.

- We use one-piece forming rollers, which support both thin and large-wave profiles without coil scratching.

- The GCr15 rollers with 0.06mm hard chrome maintain their glossy surface even after years of operation.

As a result, customers can continuously produce lightweight roofing sheets with perfect surface finish and consistent accuracy.

Production Line Configuration

| Component | Function |

|---|---|

| 1. Hydraulic Decoiler | Holds and uncoils raw steel coil, optional 5T/10T |

| 2. Guiding & Feeding Unit | Aligns the sheet and adjusts the width manually |

| 3. Roll Forming Section | 22 stations, smooth shaping with stable structure |

| 4. Servo Tracking Shearing | Cuts at high speed with ±1mm precision |

| 5. Hydraulic System | Controls decoiler and cutting functions |

| 6. Stacker System | Collects finished sheets automatically |

| 7. Electrical Control Cabinet | PLC + touch screen, user-friendly interface |

Advantages at a Glance Metal Roof Corrugated Sheets Rolling Forming Machine

Fast production speed — up to 45m/min

Precision forming — consistent shape and accuracy

Anti-scratch forming — smooth roller surface protection

Compact structure — reduced floor space requirement

Durable material — long service life and low maintenance

The High-Speed Metal Roof Corrugated Sheets Rolling Forming Machine delivers exceptional results through advanced design, smart control, and long-lasting build quality.

It is the perfect choice for manufacturers who aim for speed, precision, and reliability in metal roofing production.

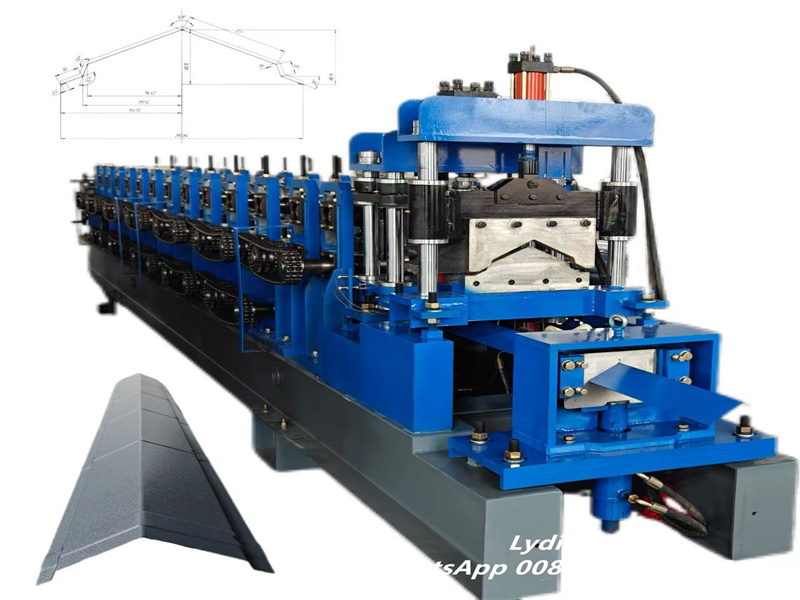

Double-Layer Ridge Capping Roll Forming Machine In modern roofing construction, ridge caps play a critical

Mangalore Tile Profile Sheet Roll Forming Machine Overview of Mangalore Tile Profile Sheet Roll Forming

Metal Ridge Capping Making Roll Forming Machine Efficient, Accurate & Worry-Free Roofing Profile Machine The

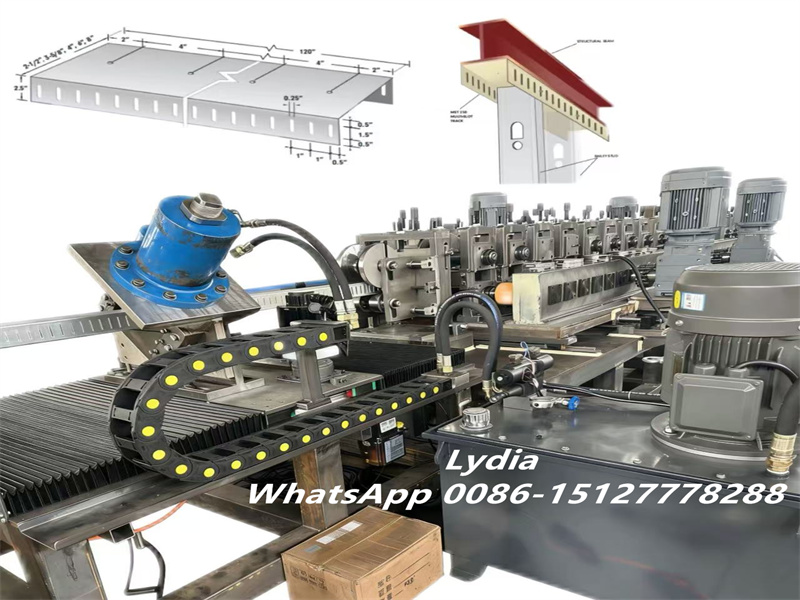

C Channel Light Steel Keel Stud and Track Roll Forming Machine High-Precision Drywall CU/CW Profile

STAY IN THE LOOP