Introducing our cutting-edge High-Speed Slitting Line—the ultimate solution for all your material slitting needs! Engineered for efficiency, this state-of-the-art AUTOMATIO SLITTING MACHINE offers a cutting thickness range of 0.5 to 4 mm and a width of 2000 mm. Designed to deliver precise, high-speed slitting across a variety of materials, it ensures smooth, seamless operation, saving you both time and effort.

ZTRFM High-Speed Slitting Lines

Manufactured by ZTRFM, a leader in Coil Processing Equipment, our High-Speed Slitting Lines deliver unrivaled results and productivity. Our slitting lines are designed for rapid changeovers, ensuring the quickest setup in the industry. We are among the few manufacturers to offer “hands-free” threading from Uncoiler to Recoiler. Additionally, our lines can be equipped with Tooling Turnstiles and Automatic Tooling Robots, reducing labor requirements, enhancing setup accuracy, and extending tooling life.

Automation in High-Speed Slitting Lines

ZTRFM’s innovative Slitting Line design allows operators to feed material strips into the Recoiler clamp automatically—without any manual handling. Our systems require minimal personnel and come equipped with state-of-the-art machine safety features. As a result, our Slitting Lines offer both enhanced safety and maximum operational efficiency, setting a new benchmark in the industry.

If you haven’t yet explored ZTRFM’s High-Speed Slitting Line, now is the time! As a pioneering Coil Processing Equipment manufacturer, we are reshaping the slitting industry, one line at a time. Contact us today at +0086-15127778288 for your next Slitting project—we promise you will be impressed.

Key Features of Our High-Speed Slitting Lines:

-“Hands-free” Uncoiler to Recoiler strip threading

-Self-nesting/side-shifting tooling bars

-Optional Choppers or Winders

-Pit crossover/tail-out system

-“Hands-free” Recoiler threading (into the gripper slot)

-Flex-Grip Recoiler gripper (automatically adjusts to the material’s crown for better grip)

-Three types of Slitting Heads/Configurations:

– Traditional Packed Arbor

– Packed Arbor with Tooling Turnstile (compatible with Automatic Tooling Robots)

– CNC Fully-Automatic

Our High Speed Slitting Lines are available with thickness capacities up to .625” (16 mm) and widths up to 96” (2438 mm)

Invest in ZTRFM’s High-Speed Slitting Line and experience the future of coil processing.

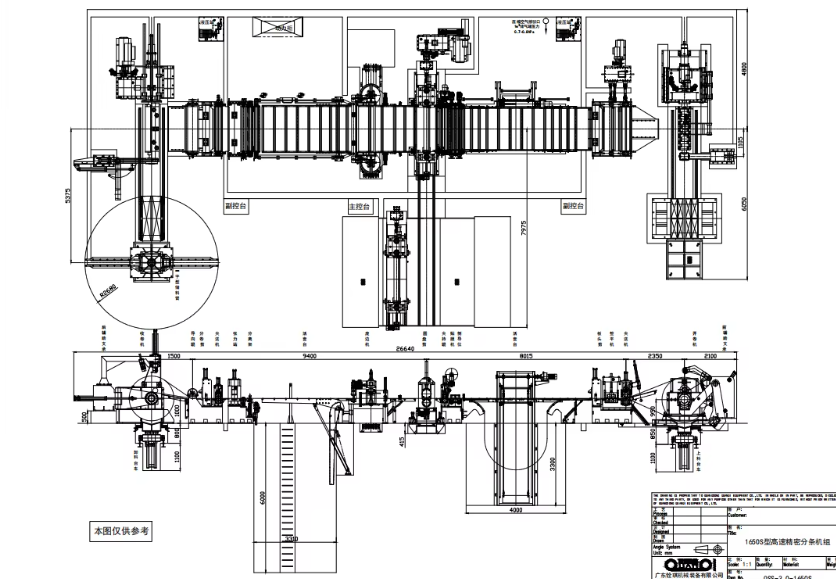

Steel Coil Slitting Line Picture simple show:

Work flow:

From right to left:Entry coil car→Decoiler→Press and pinch device→Hydraulic cutter→Looper 1→Side guide device→Slitter→Scrap winder→Looper2→Tension stand→Tension leveling→Electrostatic oil spraying system→Recoiler→Exit coil car

The Technical Specifications Of Slitting Machine:

| High Speed Metal Slitting Line For 4mm Thickness And 2 Meter Width | |

| Formed Material | PPGI, GI, Al, copper etc. |

| Material Thickness | 0.5-4.0mm |

| Material Width | 500-2000mm |

| Way of cutting | Feed cutting |

| Slitting strips | Max 10 strips |

| Stripe width | Min 60mm |

| Re-coiler diameter | Φ508mm |

| Motor Power | 11.5KW |

| Voltage | 380V 50Hz 3Phase(As your requirement) |

| Forming Speed | 100m-200m/min |

More pictures of machines:

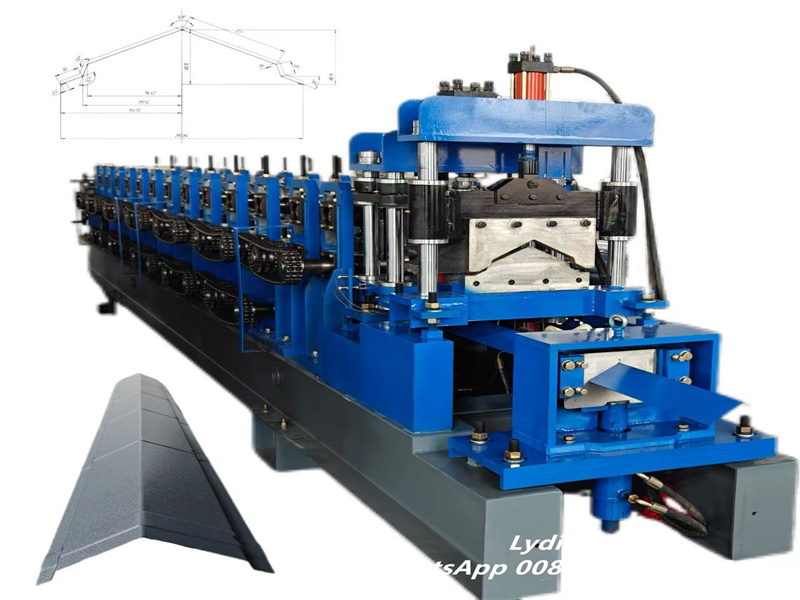

Double-Layer Ridge Capping Roll Forming Machine In modern roofing construction, ridge caps play a critical

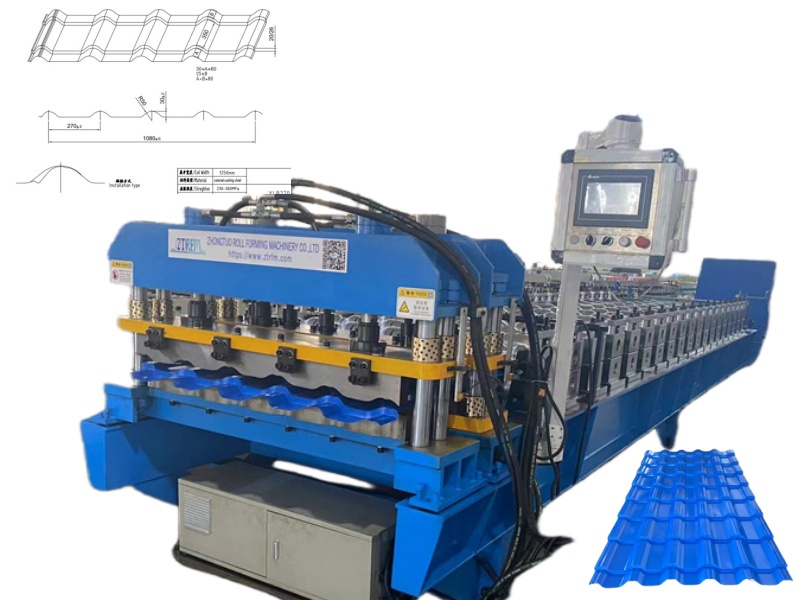

Mangalore Tile Profile Sheet Roll Forming Machine Overview of Mangalore Tile Profile Sheet Roll Forming

Metal Ridge Capping Making Roll Forming Machine Efficient, Accurate & Worry-Free Roofing Profile Machine The

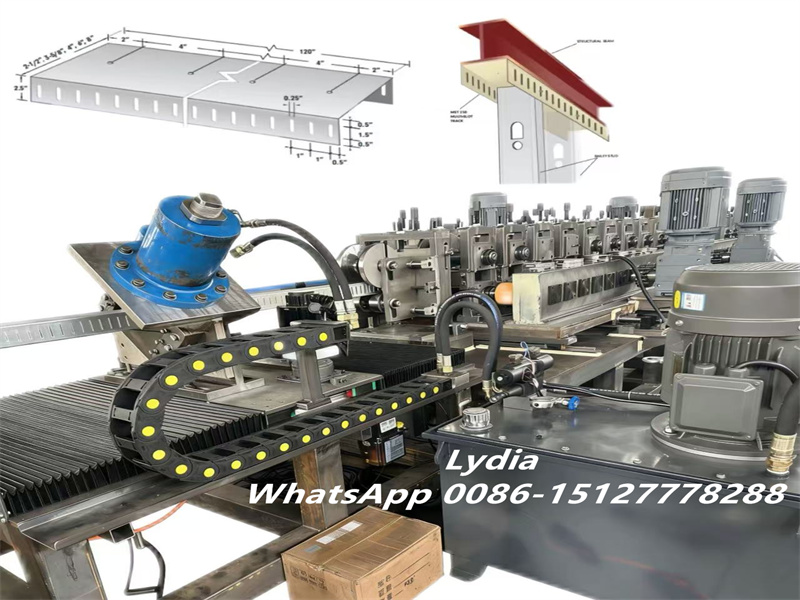

C Channel Light Steel Keel Stud and Track Roll Forming Machine High-Precision Drywall CU/CW Profile

STAY IN THE LOOP